The Lightest, Most Powerful, Tank Cleaning Machine for Large Tanks

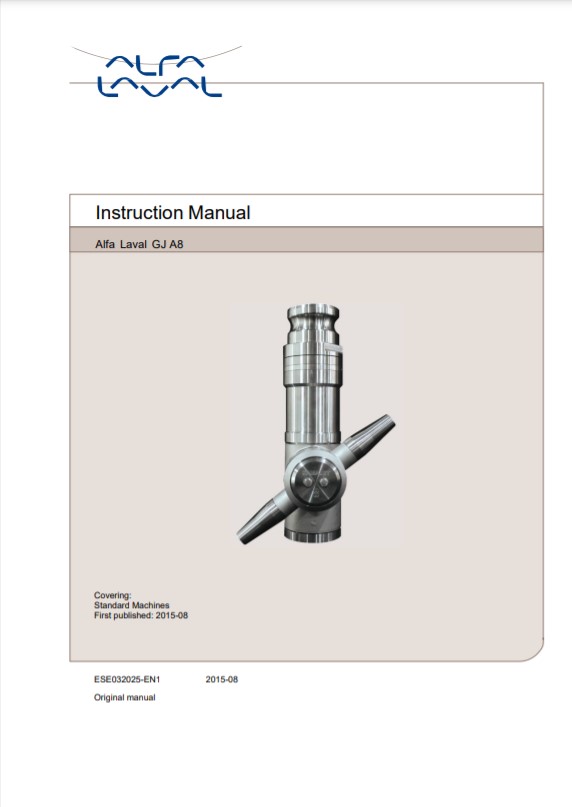

The Alfa Laval GJ A8 is the GJ 8 counterpart – lightweight, powerful, and features self-draining, self-flushing, and self-lubricating capabilities. The GJ A8 is designed completely with FDA compliant materials for hygienic applications. This versatile, fluid-driven machine features Alfa Laval’s revolutionary new gearbox that not only ensures the machine runs almost twice as long, but is also designed for quick and easy change-out in the field.

The GJ A8 is the answer to efficient, effective and hygienic CIP. Characteristic of all Alfa Laval machines, the GJ A8 utilizes patented rotary impingement cleaning technology; ensuring tanks are cleaned quickly and effectively and drastically reducing the amount of water, chemicals, and energy used during CIP. It is also designed to eliminate the need for dangerous and costly manual cleaning.

Benefits:

- Sanitary design

- Long-lasting

- Easy maintenance

- Powerful

Operating Range:

- Pressure: 20 to 1000 psi (1.4 to 69 bar)

- Temperature: 32° to 250°F (0° to 121°C)

- Flow Rate: 25 to 130 gpm (94.6 to 492 l/min)

- Cleaning Radius: 35′ (10.67 Meters)

- Wash Cycle Time: 8 Minutes

- Impact: 40 lbs (18 kg) at 25′ (7.5 m)

Clearance:

- Pin Drive:

- Dual: 8. in. (215.9 mm)

- Triple: 7.75 in. (196.85 mm)

- Clutch Drive:

- Dual: 4.75 in. (120.65 mm)

- Triple: 6.75 in. (171.45 mm)

Overall Dimensions:

- Height: 11 in. (279.4 mm)

- Body Diameter: 2.88 in. (73.2 mm)

- Weight: 15 lb (6.8 kg)

Specifications:

| Inlet Connection: | 1.5″ TC, 1.5″ Slip-fit (R-Clip), 1.5″ NPT-Female / 2″ Quick-Disconnect Male, 2″ FNPT |

|---|---|

| Construction/Design: | Parts are machined from 316-L Stainless Steel investment castings or bar stock. |

| Impeller & Final Shaft: | For increased wear resistance, the input and output shafts are plasma-sprayed with a Chromium Oxide coating on Stainless Steel. |

| Shaft & Gearbox Bushings: | Input shaft thrust is supported by a Tungsten carbide bushing. Gearbox bushings are food grade PPS or other non-cupric material. |

| Bearings: | Bearings in the rotating tee and nozzle housings are self-lubricating, carbon-fiber-reinforced polyphenylene sulfide. |

| Bearing Cups: | Main body castings are protected by replaceable 316-L Stainless Steel cups for extended frictional wear life. |

| Static Seals: | O-Ring materials are selected for each application. Food Grade EPDM is standard, Viton® with Kalrez®, Zalak® available. Other materials can be supplied on special order. |

| Dynamic Seals: | Rotary shaft and housing seals are spring-loaded, double-lipped and made of PTFE. They are reinforced for extra long wear and protection against leakage, abrasion and deposit build-up. |

| Nozzles: | Standard nozzle sizes 1/4″ (6.35 mm), 9/32″ (7.14 mm), 5/16″ (7.94 mm), 3/8″ (9.53 mm) and 7/16″ (11.11 mm). Other nozzle sizes available upon request. |

| Drive Mechanism: | The wash fluid enters the GJ A8 at the inlet collar where it encounters and spins turbine blades. The turbine blades are attached to the top of the input shaft, the bottom of this shaft is connected to the inside of a flow-thru planetary gearhead which then turns the body in the horizontal plane and the nozzles in the vertical plane. |

| Planetary Gearhead: | The flow-thru planetary gearhead has an external casing made of stainless steel. All gears are stainless steel. The gear bushings are a food grade PPS. The wash fluid is circulated through the gearbox to lubricate, clean, and take away heat from the internal gears. |

| Lubricant: | A food grade lubricant is inside the sealed gearhead casing. No customer-supplied or user-maintained lubricant is needed. |