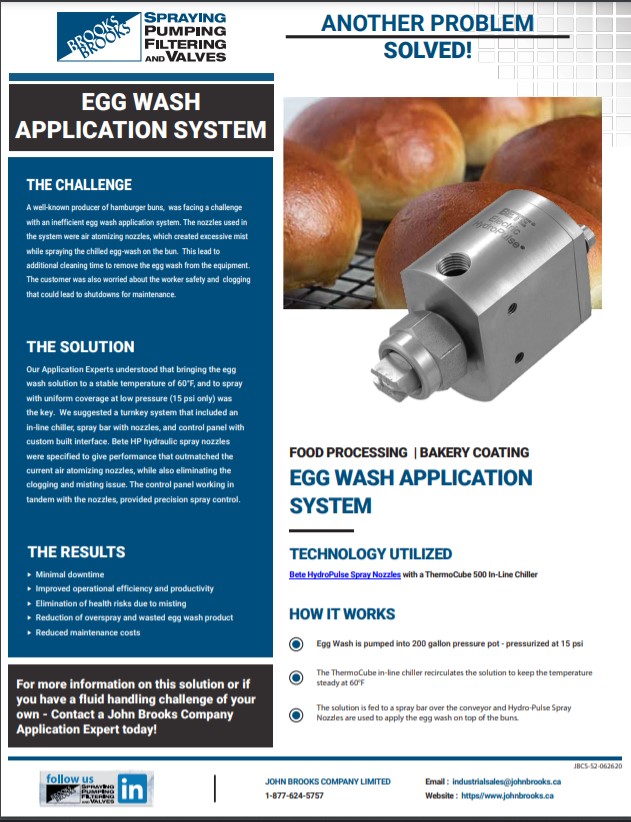

Egg Wash Application System with BETE HydroPulse Spray Nozzles

The Challenge

A well-known producer of hamburger buns, was facing a challenge with an inefficient egg wash application system. The nozzles used in the system were air atomizing nozzles, which created excessive mist while spraying the chilled egg-wash on the bun. This lead to additional cleaning time to remove the egg wash from the equipment. The customer was also worried about the worker safety and clogging that could lead to shutdowns for maintenance.

The Solution

Our spray application experts understood that bringing the egg wash solution to a stable temperature of 60°F, and to spray with uniform coverage at low pressure (15 psi only) was the key. We suggested a turnkey system that included an in-line chiller, spray bar with nozzles, and control panel with custom built interface. Bete HP hydraulic spray nozzles were specified to give performance that outmatched the current air atomizing nozzles, while also eliminating the clogging and misting issue. The control panel working in tandem with the nozzles, provided precision spray control.

The Results

- Minimal downtime

- Improved operational efficiency and productivity

- Elimination of health risks due to misting

- Reduction of overspray and wasted egg wash product

- Reduced maintenance costs

Technology Used

Bete HydroPulse Spray Nozzles with a ThermoCube 500 In-Line Chiller

How it Works

- Egg Wash is pumped into 200 gallon pressure pot – pressurized at 15 psi

- The ThermoCube in-line chiller recirculates the solution to keep the temperature

steady at 60°F - The solution is fed to a spray bar over the conveyor and Hydro-Pulse Spray

Nozzles are used to apply the egg wash on top of the buns.

For more information on this solution or if you have a fluid handling challenge of your own – Contact a John Brooks Company Application Expert today!