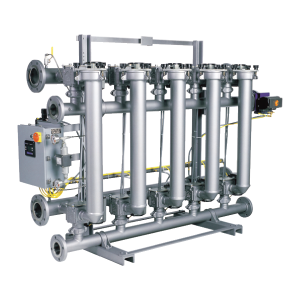

Eaton F Series Tubular Backwash Filters features a modular design that enables future capacity and configuration flexibility. It also uses cleanable media that reduces life cycle costs and maximizes productivity.

Features of the Eaton F Series Tubular Backwash Filters

- For liquid filtering applications that require unattended operation, maximum uptime, and solids removal from 1 to 1,700 microns, the F-Series family of filter systems delivers unbeatable performance.

- Versatility with a modular design that enables future capacity and configuration flexibility.

- Single system flow rates up to 3,000 gpm (681 m3/hr).

- Smooth pipe and nozzle connection transitions to avoid dead spots in the fluid stream and minimize pressure drop.

- A broad selection of filter media materials and retentions suitable for a wide range of applications.

- Proprietary 3-way, full-ported valves allow fast, frequent sequencing and maximum cleaning force during backwashing.

- Isolated top-to-bottom backwash flow ensures complete and efficient media cleaning while continuing to deliver filtered product downstream.

- Numerous automated backwash options for operator-free service and minimal backwash effluent (<2% of system volume).

- Available ACCUFLUX® media dramatically increases filter surface area in the same footprint.

|

3-Way Ball Valves To ensure positive sealing and maximum flow, our F-Series filters feature the industry’s best 3-way ball valves. These important components— designed and manufactured by Eaton exclusively for Eaton systems—were developed specifically for the demands of industrial filtration. Their full-ported design reduces pressure drop and requires no additional linkages for actuation. |

Options

- Internal or external backwashing

- Media-cleaning diffusers for more effective cleaning at low operating pressures or volumes

- Drain header trap

- Quick coupler valve connectors for ease of body tube removal

- 304 stainless steel frame material

- ASME code vessels

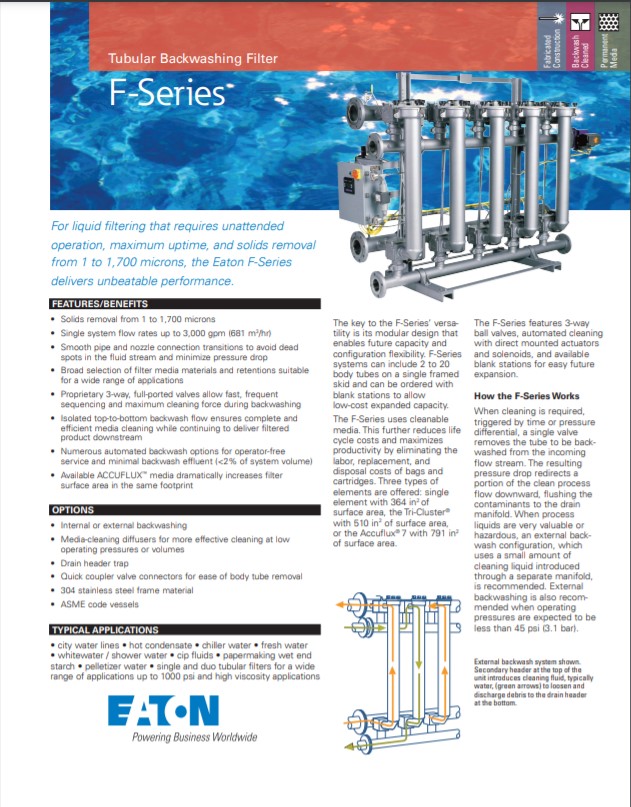

How the EATON F Series Works

When cleaning is required, triggered by time or pressure differential, a single valve removes the tube to be backwashed from the incoming flow stream. The resulting pressure drop redirects a portion of the clean process flow downward, flushing the contaminants to the drain manifold. When process liquids are very valuable or hazardous, an external back-wash configuration, which uses a small amount of cleaning liquid introduced through a separate manifold, is recommended. External backwashing is also recommended when operating pressures are expected to be less than 45 psi (3.1 bar).

EATON F Series Typical Applications

- CIP Fluids

- Chiller Water

- City Water Lines

- Fresh Water

- Hot Condensate

- Papermaking Wet End Starch

- Pelletizer Water

- Whitewater | Shower Water