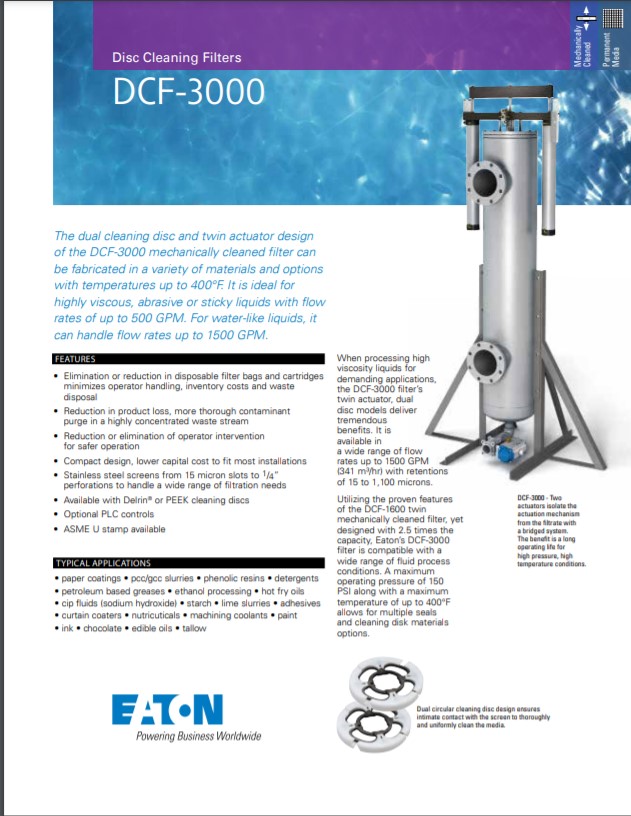

Eaton DCF 3000 Mechanically Cleaned Filters’ dual cleaning disc and twin actuator design can be fabricated in a variety of materials and options with temperatures up to 400°F. It is ideal for highly viscous, abrasive or sticky liquids with flow rates of up to 500 GPM. For water-like liquids, it can handle flow rates up to 1500 GPM.

When processing high viscosity liquids for demanding applications, the Eaton DCF 3000 filter’s twin actuator, dual disc models deliver tremendous benefits. It is available in a wide range of flow rates up to 1500 GPM (341 m³/hr) with retentions of 15 to 1,100 microns. Utilizing the proven features of the DCF 1600 twin mechanically cleaned filter, yet designed with 2.5 times the capacity, the Eaton DCF 3000 filter is compatible with a wide range of fluid process conditions. A maximum operating pressure of 150 PSI along with a maximum temperature of up to 400°F allows for multiple seals and cleaning disk materials options. Two actuators isolate the actuation mechanism from the filtrate with a bridged system. The benefit is a long operating life for high pressure, high temperature conditions.

EATON DCF 3000 Specifications

Specifications |

DCF-3000 |

|---|---|

| Approximate Weight | 350 lbs | 159 kg |

| Service Height | 136 in | 3454 mm |

| Flow Rates at 100μ | Up to 1100 GPM | 250 m³/hr |

| Operating Pressure | 30 – 150 psi | 2-10.5 bar |

| Maximum Operating Temperature | 400° F | 204° C |

| Viscosity | Water-like to 500,000+ |

| Standard Retention | 15 -1,100 microns |

| Vessel Material | 316 Stainless Steel |

| Elastomers | EPT/EPDM (Nordel™), Viton®, White Nitrile (food grade) |

| Cleaning Discs | Delrin®, PEEK |

| Packing | Urethane, Teflon®, Viton® and Glyon®/Viton® |

| Process Connections | 4-8 in 150# ANSI Flanged |

| Purge Connection | 2 in NPT | 2 in BSPT |

| Air for Actuator Drive – Clean, Dry, Non-Lubricated Air | Minimum: 80 psi | 5.5 bar min – Maximum: 116 psi | 8 bar / 5.0 cfm | 141.5 L/min |

| Electrical for Controllers | 115 VAC or 230 VAC 50/60Hz |

| Semi Auto Voltage | 24 VDC, 115 VAC, 230 VAC |

| Flooded Weight | 720 lbs | 325 kg |

Features

- Elimination or reduction in disposable filter bags and cartridges minimizes operator handling, inventory costs and waste disposal

- Reduction in product loss, more thorough contaminant purge in a highly concentrated waste stream

- Reduction or elimination of operator intervention for safer operation

- Compact design, lower capital cost to fit most installations

- Stainless steel screens from 15 micron slots to 1/4” perforations to handle a wide range of filtration needs

- Available with Delrin® or PEEK cleaning discs

- Optional PLC controls

- ASME U stamp available

Typical Applications:

- Adhesives

- CIP fluids (sodium hydroxide)

- Chocolate

- Curtain coaters

- Detergents

- Edible Oils

- Ethanol Processing

- Hot Fry Oils

- Ink

- Lime Slurries

- Machining Coolants

- Nutricuticals

- PCC|GCC Slurries

- Paint

- Paper Coatings

- Petroleum Based Greases

- Phenolic Resins

- Starch

- Tallow