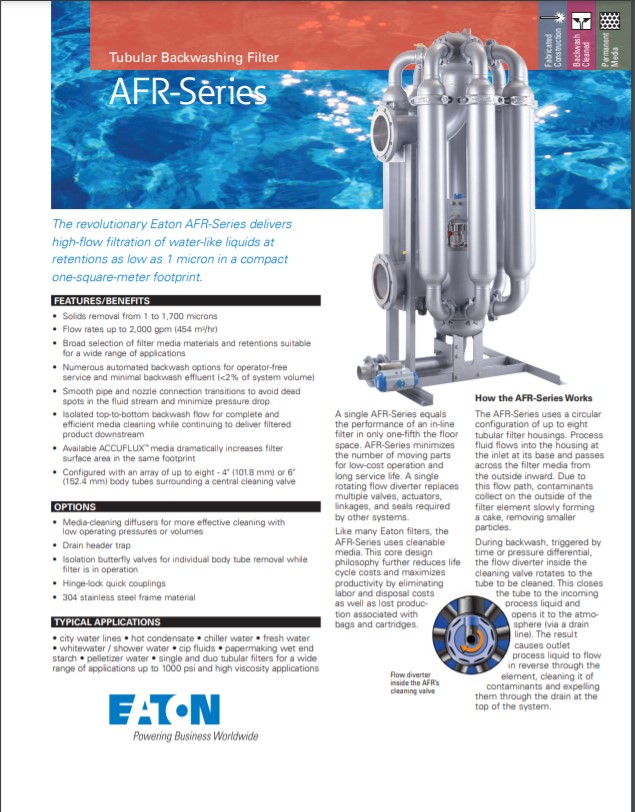

EATON AFR Series tubular backwashing filters features a unique, expandable circular design for increased capacity in a compact one-square-meter footprint. The Eaton AFR Series uses Ronningen-Petter technology for ideal for high volume, low viscosity applications with retentions as low as 2 microns.

EATON AFR High Performance & High Volume

Increased capacity and space saving:

- Solids removal from 1 to 1,700 microns

- Flow rates up to 2,000 gpm (454 m3/hr)

- Broad selection of filter media materials and retentions suitable for a wide range of applications

- Numerous automated backwash options for operator-free service and minimal backwash effluent (<2% of system volume)

- Smooth pipe and nozzle connection transitions to avoid dead spots in the fluid stream and minimize pressure drop

- Isolated top-to-bottom backwash flow for complete and efficient media cleaning while continuing to deliver filtered product downstream

- Available ACCUFLUX™ media dramatically increases filter surface area in the same footprint

- Configured with an array of up to eight – 4″ (101.8mm) or 6″; (152.4 mm) body tubes surrounding a central cleaning valve

Options:

- Media-cleaning diffusers for more effective cleaning with low operating pressures or volumes

- Drain header trap

- Isolation butterfly valves for individual body tube removal while filter is in operation

- Hinge-lock quick couplings

- 304 stainless steel frame material

Cost reduction:

- A single AFR Series filter can replace a 13- station multiplexed system.

- For even higher flow rates, AFR Series filters can be easily combined.

Specifications:

- Connection Inlet and Outlet: 8” ANSI or 200 mm DIN flanged. Drain: 3”(80 mm) weld stub

- Process Parameters Temperature: 300°F (149°C) maximum (determined by screen material and elastomer seals). Operating pressure: up to 250 psi (17 bar)

- Elastomer Seals Standard: Buna-N (180°F (82°C) max). Optional: Nordel (230°F (110°C) max); Viton® (300°F (149°C) max)

- Housing/ Wetted Parts Materials Standard: 316 stainless steel. Optional: Wide range available; consult Eaton

- Frame Material Standard: Painted carbon steel. Optional: 304 stainless steel

- Automation Standard: Choice of programmable logic controller (PLC) or semi-automatic. Optional: Wide range available

- Utilities Electrical: 110 or 220 Volt, 50 or 60 Hz, single-phase. Air: 60-120 psi (4.1-8.3 bar) @ 5 cfm. Air must be clean, dry and non-lubricated

Applications of Eaton AFR Series Tubular Backwashing Pressure Filter:

- Chemical Filtration

- Food and Beverage Filtration

- Manufacturing Process Filtration

- Oil and Gas Refining

- Petrochemical Processing

- Wastewater Treatment

- Water Treatment

- Pre-RO Filtration

- Seal Protection

- Heat Exchanger Protection