EATON 10 R Two Stage Gas Liquid Separators are designed for liquid slugs or heavy liquid loads, the Eaton standard size Type 10 R Series gas liquid separators can be provided with a large reservoir to meet liquid holdup requirements. Eaton provides a compact model for applications where space is restricted.

EATON 10 R Two Stage Gas Liquid Separators Features

- Standard and Compact Models

- Capable of Handling Slugs of Liquids

- Removes 99% of Liquid and Solid Entrainment Particles Larger than 10 Microns

- ASME Code Stamp

- Two 1/2” NPT Water Gauge Connections

- One 1/2” NPT Vent Connection

- No Required Maintenance

- Gas, Steam, or Air Applications

Options

- Support stand

- Fabricated carbon steel or stainless steel construction, with internal vane blades made of 304L stainless steel

- Multiple inlets and/or outlets

- Sizes larger than 16”

EATON 10 R Gas Liquid Separators Applications

EATON 10 R Gas Liquid Separators are widely used in the chemical and process industries where large volumes of liquid must be separated from gases. They also may be used as a flash or surge tank, or as a scrubber or demister ahead of steam turbines.

Operation

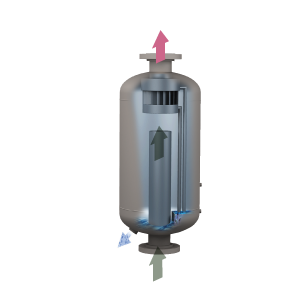

EATON 10 R Gas Liquid Separators have two stages for separating large volumes of liquid from a smaller volume of a gas or vapor. In stage one, the flow enters the inlet and is deflected downward by an impingement plate, causing it to lose velocity. This results in

the majority of the liquid dropping into a reservoir. In the second stage, the moisture

laden gas passes through a vane element where any remaining moisture is separated and flows down into the reservoir. The separator removes all liquid and solid entrainment where the

particle size is 10 microns or greater.

EATON 10 R Gas Liquid Separators Construction

Eaton Type 10 R Gas Liquid Separators are constructed in accordance with the ASME Code Section VIII, Division 1 and are code stamped. They are available with 150 lb. slip on raised face flanges rated at 200 psi at 300 °F or with 300 lb. slip on raised face flanges rated at 250 psi at 650 °F. They feature fabricated carbon steel construction, with internal vane blades made of 304L stainless steel.

Expert Help is Available

Choosing the right gas/liquid separator can present unique problems not encountered in choosing other pipeline components. Why not take advantage of our application experience with gas/liquid separators? Application specialists are available to help you every step of the way…from initial selection, to installation and through start-up…