How We Worked with a Municipality to Decrease Sewage Production with the E/One Indoor Grinder Pump

The Challenge: Low Sewer Capacity Stalled Home Development Potential

A home builder/developer in Trenton, Ontario, struggled with some neighborhood developments because the municipality needed to increase the wastewater treatment (WWTP) sewer capacity. As a result, the builders required a low-flow alternative to gravity sewers that would solve the limitation challenges of the municipality’s system.

The Solution: Basement Grinder Pump Stations

First, our application experts worked with E/One to create a low-pressure sewer design for the customer’s development. Then, after the design was complete, we met with the municipality to show our solution and provide several established E/One installation references to demonstrate the potential for success.

We proposed that the E/One Indoor Grinder Pump (as part of our low-pressure sewer system solution) would remove infiltration and intrusion water from sewers—cutting sewage produced by 50%. The municipality approved a test installation of our system. It required that we install a metering chamber at the end of the development’s street where they could monitor and confirm our numbers.

The Result: 50% Decrease in Sewage Production & Reduced Costs

The test installation was a success. The municipality confirmed a 50% reduction in produced sewage and approved a permanent installation.

The results were:

- A 50% decrease in produced sewage

- Greater efficiency as the E/One system pumps only the household sewage instead of the ground and surface water in conventional sewers

- The system works so well that the customer has used it in 84 other builds

E/One System Lowered Upfront Costs for the Customer

The upfront costs for the customer were lower because:

- The E/One sewer design doesn’t have air release chambers or manholes, which are 2x the cost of low-pressure, small-diameter force mains.

- There was no initial capital cost for a sewage lift station, saving the customer between $250,000 to $500,000.

- Since there is no sewage lift station, the customer saves on those operating costs, typically between $30,000 and $35,000 per year.

Sewer System & Pump Technology Used

We designed a low-pressure sewer system with E/One’s IH901 Indoor Stations to solve the customer’s problems.

E/One IH901 Indoor Grind Pump Station Specs

- Capacity: 91 gal (344.47 L)

- Flow: 7 – 15 gpm (26.5 to 56.78 lpm),

- Pressure: 0 – 80 psi (0 – 5.51 bar)

- Inlet Velocity: 2 ft/sec (1.09 m/sec)

- Motor: 1HP, 1725 rpm

- Energy Efficiency: 6 kWh – 23 kWh/month to operate

- Stainless steel unilateral valves that prevent backflow

- Adaptable 1-1/4” discharge connection

- Corrosion-resistant HDPE tank

How Grinder Pump Stations Work

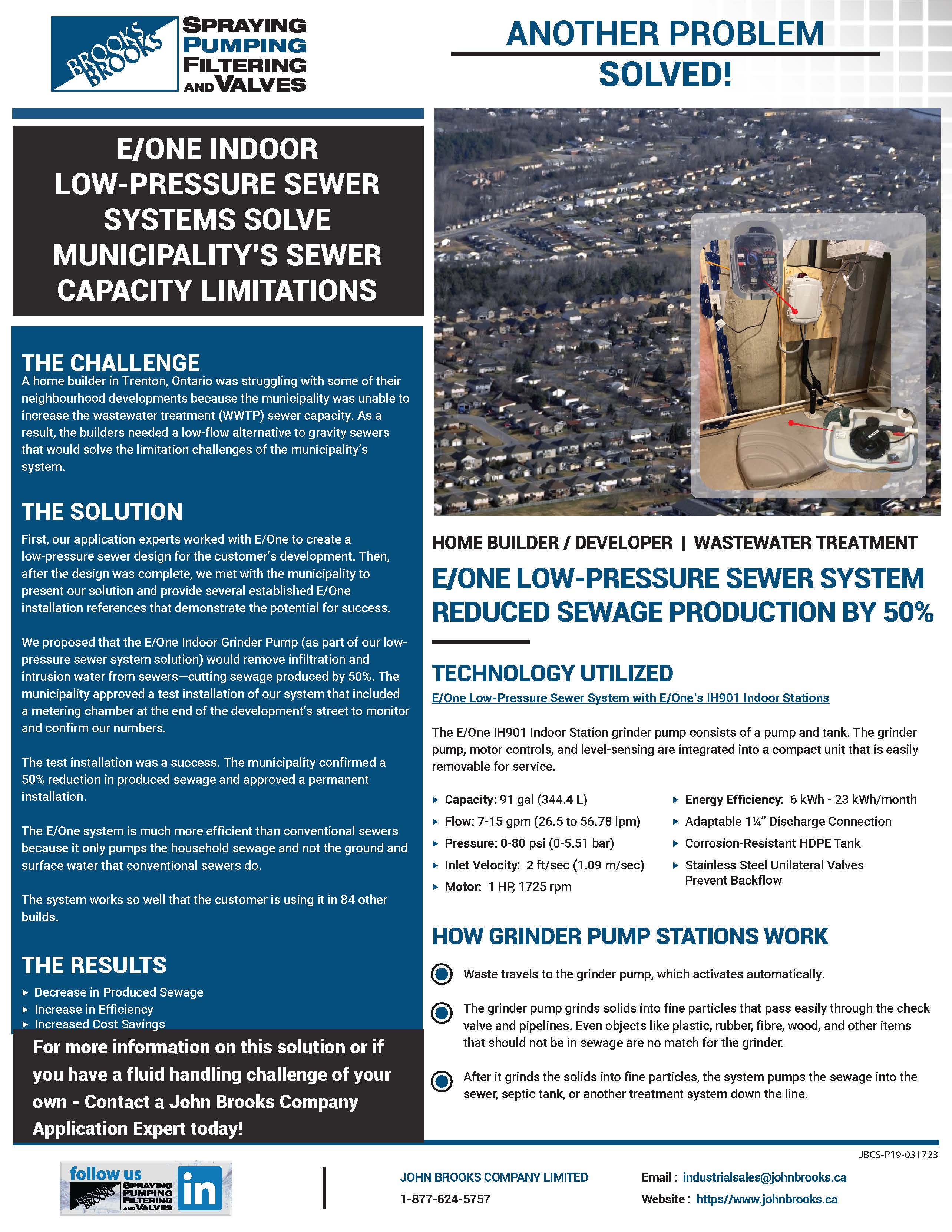

The E/One IH901 Indoor Station grinder pump consists of a pump and tank. The grinder pump, motor controls, and level-sensing are integrated into a compact, easily removable unit for service.

Waste travels to the grinder pump, which activates automatically. The grinder pump grinds solids into fine particles that pass quickly through the check valve and pipelines. Even objects like plastic, rubber, fibre, wood and other items that should not be in sewage are no match for the grinder. After it grinds the solids into fine particles, the system pumps the sewage into the sewer, septic tank, or another treatment system.

The pump runs infrequently and for brief periods making its annual electric energy consumption about the same as a 40-Watt light bulb.

E/One grinder pumps do not require preventive maintenance and boast an average of eight to 10 years between service calls. In addition, the one-piece core eliminates the need for in-field troubleshooting and servicing if service is required. The pump core can be quickly removed and replaced, meaning minimal maintenance costs and inconvenience for the homeowner.