™Custom Spray Nozzle Solutions – SpiralAir™ with 25° offset body to fit into custom geometry inlet

Application #060236

Industry: Waste Management

Application: Dry Scrubbing

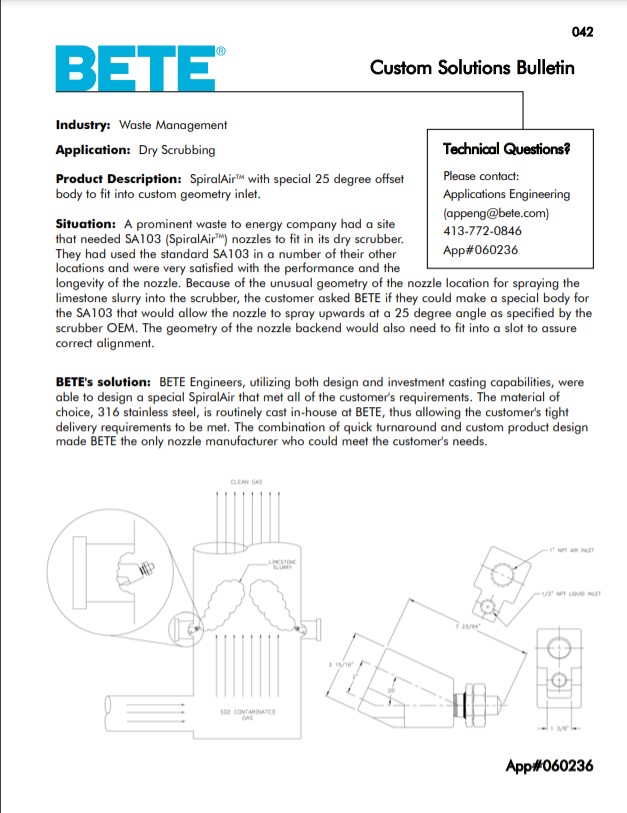

Product Description: SpiralAirTM with special 25° offset body to fit into custom geometry inlet

Situation: A prominent waste to energy company had a site that needed SA103 (SpiralAirTM) nozzles to fit in its dry scrubber. They had used the standard SA103 in a number of their other locations and were very satisfied with the performance and the longevity of the nozzle. Because of the unusual geometry of the nozzle location for spraying the limestone slurry into the scrubber, the customer asked BETE if they could make a special body for the SA103 that would allow the nozzle to spray upwards at a 25 degree angle as specified by the scrubber OEM. The geometry of the nozzle backend would also need to fit into a slot to assure correct alignment.

Solution: BETE Engineers, utilizing both design and investment casting capabilities, were able to design a special SpiralAir that met all of the customer’s requirements. The material of choice, 316 stainless steel, is routinely cast in-house at BETE, thus allowing the customer’s tight delivery requirements to be met. The combination of quick turnaround and custom product design made BETE the only nozzle manufacturer who could meet the customer’s needs.