Custom Spray Nozzle Solutions – Seawater Flue Gas Desulphurization

Application #060995

Industry: Utilities

Application: Seawater Flue Gas Desulphurization (FGD)

Product Description: Special 4″ FL Bete ST 161 XFCN

Situation: A Bete customer in the early stages of design of a seawater flue gas desulphurization (FGD) called upon BETE’s extensive background in the design of nozzles for traditional FGD applications to provide recommendations for their seawater system. The initial design called for approximately 1 million L/min (264,000 GPM) of seawater to be used in the scrubber.

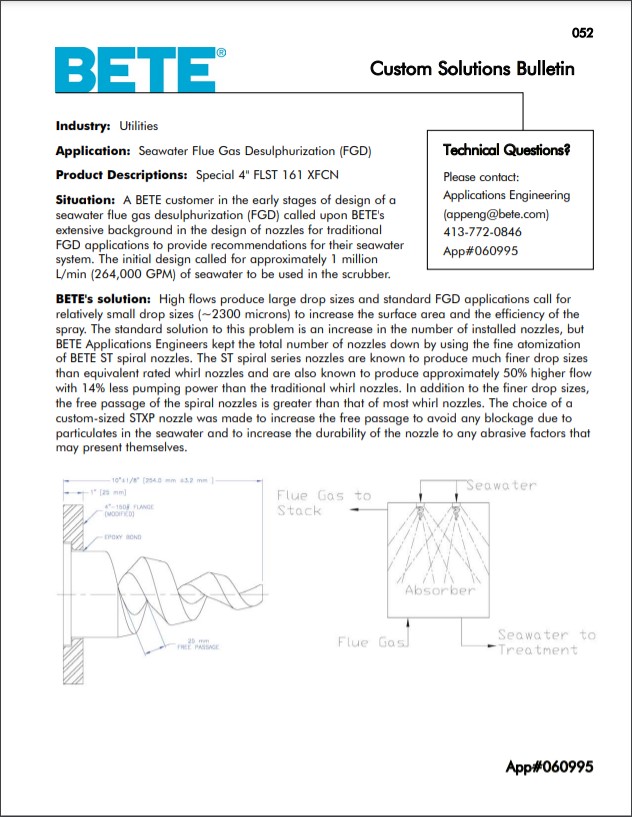

Solution: High flows produce large drop sizes and standard FGD applications call for relatively small drop sizes (~2300 microns) to increase the surface area and the efficiency of the spray. The standard solution to this problem is an increase in the number of installed nozzles, but Bete Applications Engineers kept the total number of nozzles down by using the fine atomization of Bete ST spiral nozzles. The ST spiral nozzles are known to produce much finer drop sizes than equivalent rated whirl nozzles and are also known to produce approximately 50% higher flow with 14% less pumping power than the traditional whirl nozzles. In addition to the finer drop sizes, the free passage of the spiral nozzles is greater than that of most whirl nozzles. The choice of a custom-sized STXP spiral nozzles was made to increase the free passage to avoid any blockage due to particulates in the seawater and to increase the durability of the nozzle to any abrasive factors that may present themselves.

Custom Spray Nozzle Solutions – Seawater Flue Gas Desulphurization Drawings and Sketches: