Custom Spray Nozzle Solutions – Evaporative Flue Gas Cooling

Application #090491

Industry: Steel

Application: Quenching Flue Gas

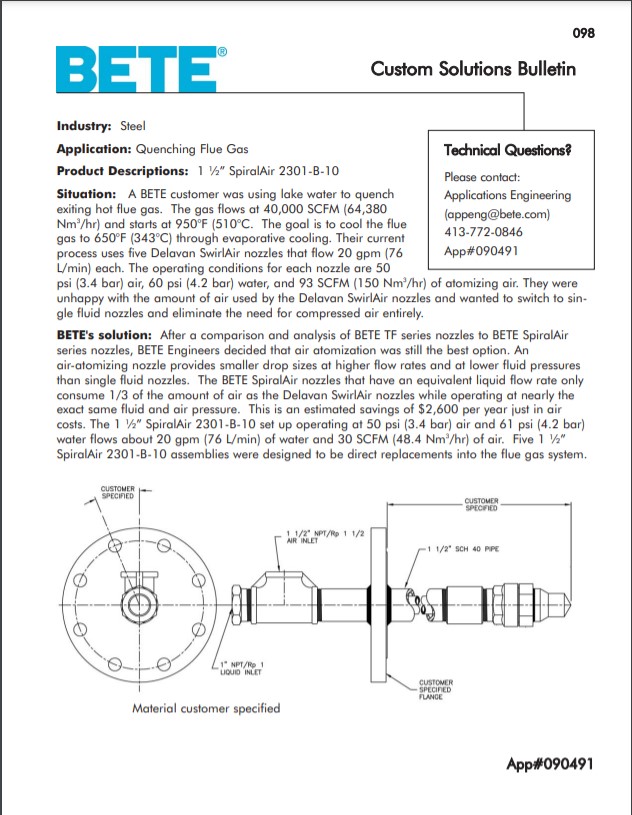

Product Description: 1 ½” Bete SpiralAir 2301-B-10

Situation: A Bete customer was using lake water to quench exiting hot flue gas. The gas flows at 40,000 SCFM (34,380 Nm³/hr) and starts at 950°F (510°C). The goal is to cool the flue gas to 650°F (343°C) through evaporative cooling. Their current process uses five Delavan SwirlAir nozzles that flow 20 gpm (76 L/min) each. The operating conditions for each nozzle are 50 psi (3.4 bar) air, 60 psi (4.2 bar) water, and 93 SCFM (150 Nm³/hr) of atomizing air. They were unhappy with the amount of air used by the Delavan SwirlAir nozzles and wanted to switch to single fluid nozzles and eliminate the need for compressed air entirely.

Solution: After a comparison and analysis of Bete TF series nozzles to Bete SpiralAir series nozzles, BETE Engineers decided that air atomization was still the best option. An air-atomizing nozzle provides smaller drop sizes at higher flow rates and at lower fluid pressures than single fluid nozzles. The Bete SpiralAir nozzles that have an equivalent liquid flow rate only consume 1/3 of the amount of air as the Delavan SwirlAir nozzles while operating at nearly the exact same fluid and air pressure. This is an estimated savings of $2,600 per year just in air costs. The 1 ½” SpiralAir 2301-B-10 set up operating at 50 psi (3.4 bar) air and 61 psi (4.2 bar) water flows about 20 gpm (76 L/min) of water and 30 SCFM (48.4 Nm³/hr) of air. Five 1 ½” SpiralAir 2301-B-10 assemblies were designed to be direct replacements into the flue gas system.

Custom Spray Nozzle Solutions – Evaporative Flue Gas Cooling Drawings and Sketches:

.jpg)