Custom Spray Nozzle Solutions – Coating System

Application #051291

Industry: Home Building Materials

Application: Coating

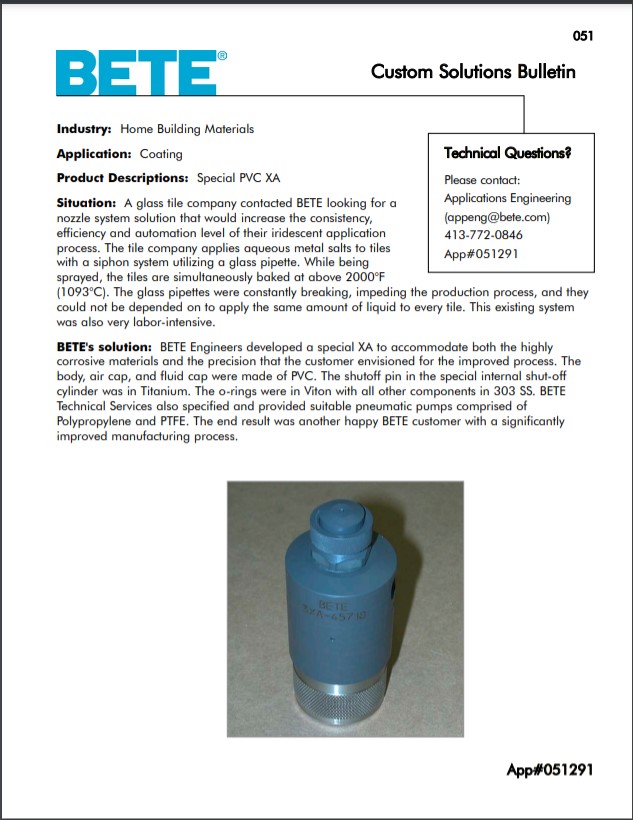

Product Description: Special PVC Bete XA

Situation: A glass tile company contacted Bete looking for a nozzle system solution that would increase the consistency, efficiency and automation level of their iridescent application process. The tile company applies aqueous metal salts to tiles with a siphon system utilizing a glass pipette. While being sprayed, the tiles are simultaneously baked at above 2000°F (1093°C). The glass pipettes were constantly breaking, impeding the production process, and they could not be depended on to apply the same amount of liquid to every tile. The existing system was also very labor-intensive.

Solution: Bete Engineers developed a special XA nozzle to accommodate both the highly corrosive materials and the precision that the customer envisioned for the improved process. The XA body, air cap and fluid cap were made of PVC. The shutoff pin in the special internal shut-off cylinder was in Titanium. The o-rings were in Viton with all other components in 303 SS. Bete Technical Services also specified and provided suitable pneumatic pumps comprised of Polypropylene and PTFE.

Custom Spray Nozzle Solutions – Coating System Drawings and Sketches: