Custom Spray Nozzle Solutions – Coal Dumping Station Dust Suppression

Application #080596

Industry: Coal

Application: Dust Suppression

Product Description: 3/8″ Bete TF in 316 SS

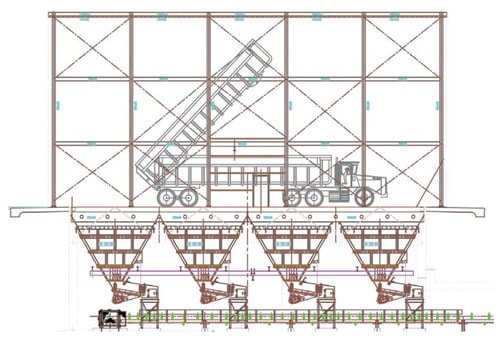

Situation: An engineering firm contacted BETE looking for assistance in designing a dust control system for a coal dumping station. Dump trucks carrying coal drive into the enclosed station and dump the coal into one of four hoppers located beneath the road surface. The hoppers deposit the coal onto a main conveyor belt to be transported. A dust suppression system at the dumping point was required to maintain a safe and clean environment and to ensure that all of the coal makes it to the conveyor belt.

Solution: The droplet size distribution and spray pattern produced by the Bete TF original spiral nozzle are ideal for the application. The solution proposed by BETE employed the 3/8″ TF12FCN operating at 100 psi (9.5 gpm each). They were placed 6 ft above the hoppers on headers along each sidewall, at a distance of every 5 ft. Nozzle coverage was verified in BETE’s spray test laboratory to ensure adequate spray width and distance. Only the nozzles in the area of the coal being dumped operated at any given time, thus maintaining the desired environment.

Custom Spray Nozzle Solutions – Coal Dumping Station Dust Suppression Drawings and Sketches:

.jpg)