Custom Spray Nozzle Solutions – Cheese Mould Washing

Application #070839

Industry: Food Processing

Application: Cheese Mould Washing

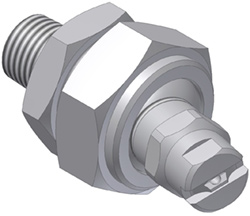

Product Description: 1/4″ Bete NF Nozzles with Bete SJ Swivel Joints

Situation: A cheese making company contacted Bete with the intent to improve the performance of their cheese mould washer. Their washer originally came with 6 headers on the top and 6 headers on the bottom of a conveyor belt that moves at 20 ft/minute (6.1 m/min). The headers were in groups of three running parallel to the belt. Fan nozzles on the headers were oriented straight down at the belt. Mould dimensions range from heights of 1 to 9 in (2.5 to 23 cm) and diameters of 7 to 18 in (18 to 46 cm).

Solution: The decision was made to add two side headers in order to improve performance. The washer was further optimized with the installation of Swivel Joints on some of the top and side headers. These allowed certain nozzles to be angled towards the moulds, which travel down the center of the conveyor. The table below indicates which nozzles were used in each location.

| Location | Nozzle |

| Top, Outside | ¼”NF10-90 with SJ |

| Top, Center | ¼”NF10-90 |

| Bottom, Outside | ¼”NF10-90 |

| Bottom, Center | ¼”NF10-120 |

| Side, Bottom | ¼”NF15-20 with SJ |

| Side, Top | ¼”NF15-120 |

Custom Spray Nozzle Solutions – Cheese Mould Washing Drawings and Sketches: