Custom Spray Nozzle Solutions – Air-Atomized Spray Drying

Application #070891

Industry: Food Processing

Application: Spray Drying

Product Description: 3″ Bete SpiralAir (SA) 3101 Nozzle

Situation: Customers often purchase Bete SpiralAir nozzles for air-atomized spray drying. The use of air-atomized SpiralAir nozzles allow high product flow rates while still maintaining a relatively small particle size, usually less than a 100 micron Sauter Mean Diameter (D32). The replaceable Cobalt Alloy 6 wear components available for this nozzle allow it to have comparable wear life to traditional spray dry nozzles. This particular customer had been using SpiralAir nozzles for spray drying for some time, and was happy with the results. However, they were building a new, much larger drier, and wanted to use a single nozzle to spray 5 – 40 GPM (20 – 150 l/min) of product.

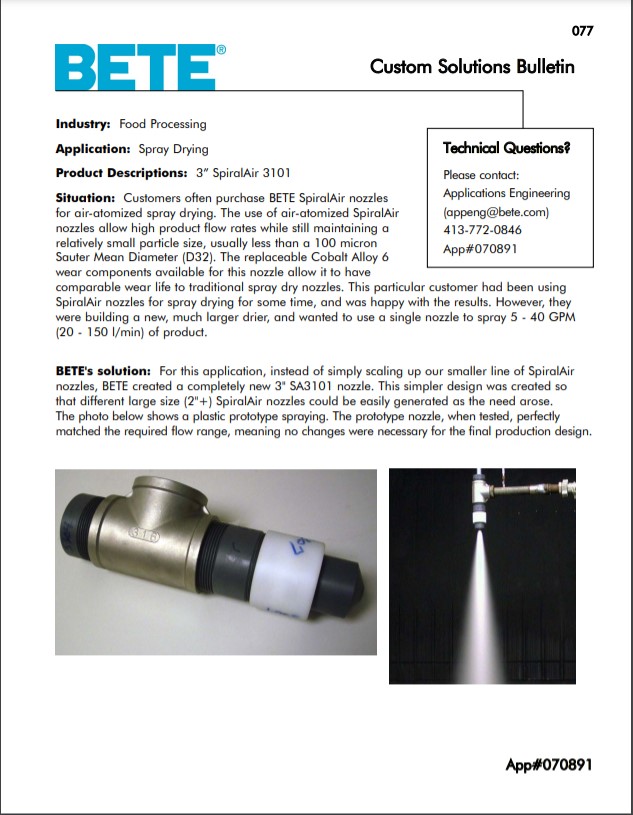

Solution: For this application, instead of simply scaling up a smaller line of SpiralAir nozzles, Bete created a completely new 3″ SA3101 nozzle. This simpler design was created so that different large size (2″+) SpiralAir nozzles could be easily generated as the need arose. The photo below shows a plastic prototype spraying. The prototype nozzle, when tested, perfectly matched the required flow range, meaning no changes were necessary for the final production design.

Custom Spray Nozzle Solutions – Air-Atomized Spray Drying Drawings and Sketches:

.jpg)