Custom Spray Nozzle Solutions – Biodiesel Mixing Nozzles

Application #080401

Industry: Petroleum Processing

Application: Mixing/Agitation

Product Description: 3″ Bete TurboMix 1500

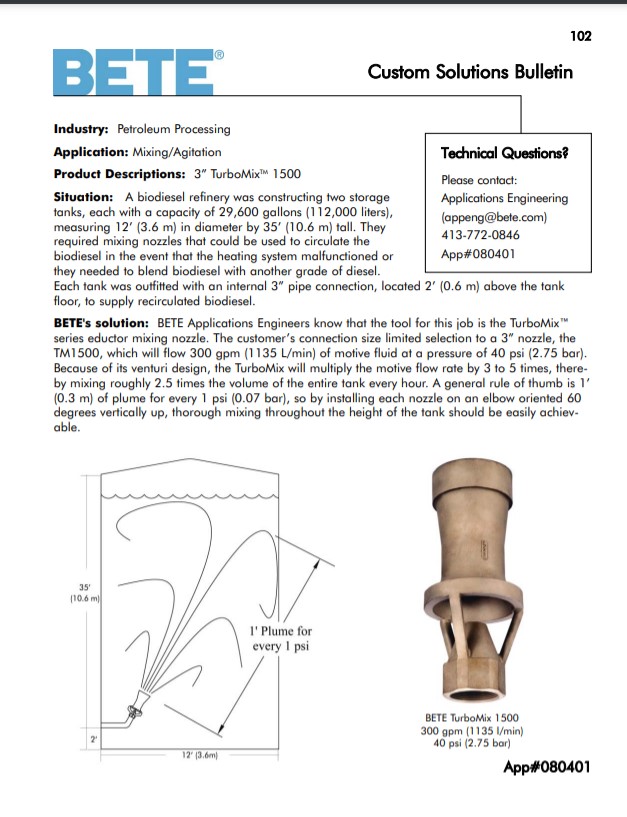

Situation: A biodiesel refinery was constructing two storage tanks, each with a capacity of 29,600 gallons (112,000 liters), measuring 12′ (3.6 m) in diameter by 35′ (10.6 m) tall. They required mixing nozzles that could be used to circulate the biodiesel in the event that the heating system malfunctioned or they needed to blend biodiesel with another grade of diesel. Each tank was outfitted with an internal 3″ pipe connection, located 2′ (0.6 m) above the tank floor, to supply recirculated biodiesel.

Solution: Bete Applications Engineers know that the tool for this job is the TurboMix series eductor mixing nozzle. The customer’s connection size limited selection to a 3″ nozzle, the TM1500, which will flow 300 GPM (1135 l/min) of motive fluid at a pressure of 40 psi (2.75 bar). Because of its venturi design, the TurboMix will multiply the motive flow rate by 3 to 5 times, thereby mixing roughly 2.5 times the volume of the entire tank every hour. A general rule of thumb is 1′ (0.3 m) of plume for every 1 psi (0.07 bar), so by installing each nozzle on an elbow oriented 60 degrees vertically up, thorough mixing throughout the height of the tank should be easily achievable.

Custom Spray Nozzle Solutions – Biodiesel Mixing Nozzles Drawings and Sketches: