Custom Spray Nozzle Solutions – Aqueous Ammonia Injection

Application #090811

Industry: Utilities

Application: Aqueous Ammonia Injection for Selective Catalyst Reduction (SCR)

Product Description: Bete SpiralAir with Protection Air Shroud

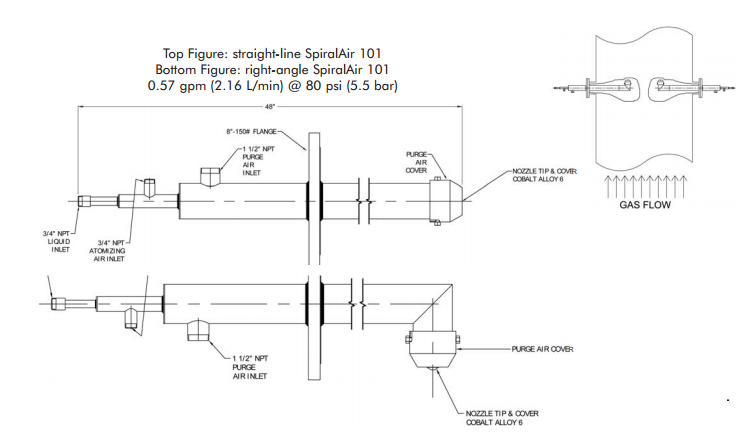

Situation: The customer, a power plant OEM, had a preliminary specification for a coal-fired power plant SCR system. They wanted to spray 0.57 (2.16 L/min) to 0.62 gpm (2.35 L/min) of a 29% aqueous ammonia solution into the power plant flue gas stream to control NOx emissions. The available air pressure was up to 80 PSI (5.5 bar). Droplet size was to be minimized to ensure complete evaporation. The material of construction requested was 316 stainless steel. The lances were to have a 8″ 150# mounting flange. Because this was a preliminary specification, the OEM requested two options, a straight-line configuration as well as a right-angle configuration.

Solution: The Bete SpiralAir101 provided the exact flow rates needed at 80 PSI (5.5 bar) of atomizing air and a liquid pressure of 82 to 87 PSI. The spray angle of 15-20 degrees was optimal to prevent spray from hitting the walls of the duct and the Sauter mean droplet size range around 25 microns to allow for complete evaporation. Because this was a custom solution, Bete was able to design to whatever protection air flow rate was required.

Custom Spray Nozzle Solutions – Aqueous Ammonia Injection Drawings and Sketches:

.jpg)