We Customized a Cartridge Filter Solution to Increase the Efficiency of the Uranium Mine’s Cooling Loop Heat Exchanger System

The Challenge

Unfiltered Sediment in Cooling Brine Caused Build-up on Heat Exchanger Plates

After mining uranium ore, cooling pipes inject brine into the ore body to freeze it for transport. The cooling brine (-25°C to -35°C) is pumped through the pipes, extracting heat from the ore body to accomplish the freezing process, and the energy created by the freezing process has to be removed by a series of heat exchangers.

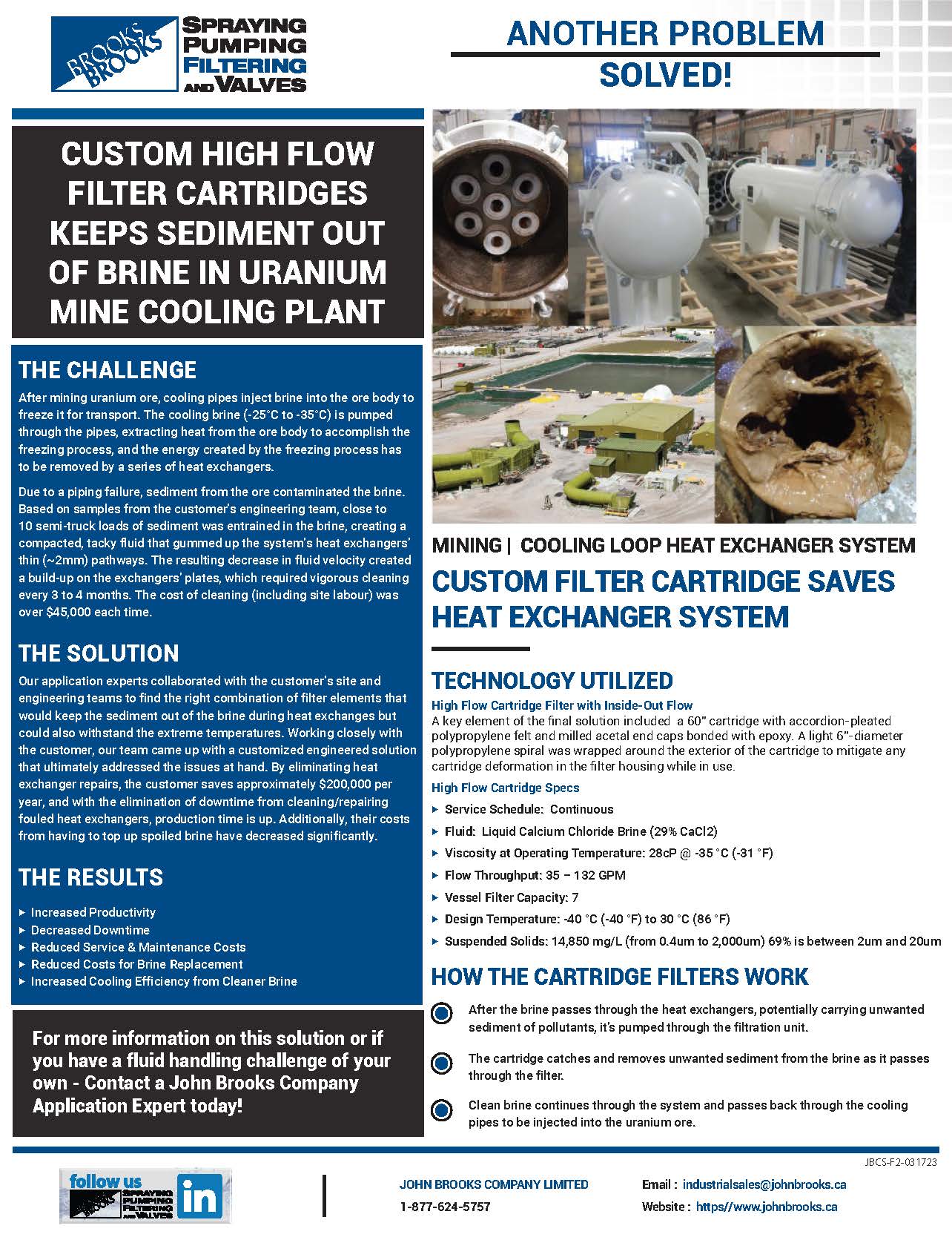

Due to a piping failure, sediment from the ore contaminated the brine. Based on samples from the customer’s engineering team, close to 10 semi-truck loads of sediment was entrained in the brine, creating a compacted, tacky fluid that gummed up the system’s heat exchangers’ thin (~2mm) pathways. The resulting decrease in fluid velocity created a build-up on the exchangers’ plates, which required vigorous cleaning every 3 to 4 months. The cost of cleaning (including site labour) was over $45,000 each time.

The Solution

A Customized Filter Cartridge Built to Withstand Extreme Cold Temperatures

Our application experts collaborated with the customer’s site and engineering teams to find the right combination of filter elements that would keep the sediment out of the brine during heat exchanges but could also withstand the extreme temperatures.

Working closely with the customer, our team came up with a customized engineered solution that ultimately addressed the issues at hand.

The Custom High Flow Cartridge

A key element of the final solution included a 60” cartridge with accordion-pleated polypropylene felt and milled acetal end caps bonded with epoxy. A light 6”-diameter polypropylene spiral was wrapped around the exterior of the cartridge to mitigate any cartridge deformation in the filter housing while in use.

The Result

Clean Brine and Reduced Maintenance and Operations Costs

This customized engineered solution’s primary benefit to the customer was a decrease in maintenance and operation costs. By eliminating heat exchanger repairs, the customer saves approximately $200,000 per year, and with the elimination of downtime from cleaning/repairing fouled heat exchangers, production time is up. Additionally, their costs from having to top up spoiled brine (which is even more expensive given the customer’s remote location) have decreased significantly.

Since installing the designer filter cartridge, the customer has:

- Increased productivity

- Decreased downtime

- Reduced service & maintenance costs

- Reduced costs for brine replacement

- Increased cooling efficiency from cleaner brine

Filter Cartridge Technology Used

We used a custom high flow cartridge filter with inside-out flow to solve the customer’s problems.

Filter Cartridge Specs

- Service Schedule: Continuous

- Fluid: Liquid Calcium Chloride Brine (29% CaCl2)

- Viscosity at Operating Temperature: 28cP @ -35 °C (-31 °F)

- Flow Throughput: 35 – 132 GPM

- Vessel Filter Capacity: 7

- Design Temperature: -40 °C (-40 °F) to 30 °C (86 °F)

- Suspended Solids: 14,850 mg/L (from 0.4um to 2,000um) 69% is between 2um and 20um

How the Cartridge Filters Work

After the brine passes through the heat exchangers, potentially carrying unwanted sediment of pollutants, it’s pumped through the filtration unit.

The cartridge catches and removes unwanted sediment from the brine as it passes through the filter.