Ductile-Iron Pump Capable of Handling Liquids with Suspended Particles

________________________________________________________________________________________________________________________

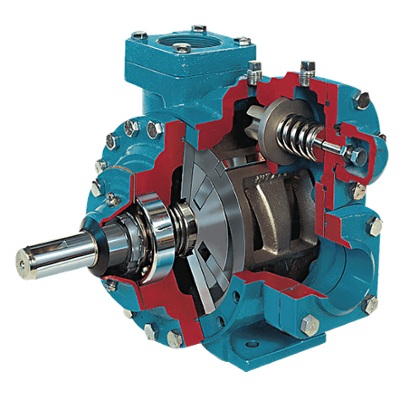

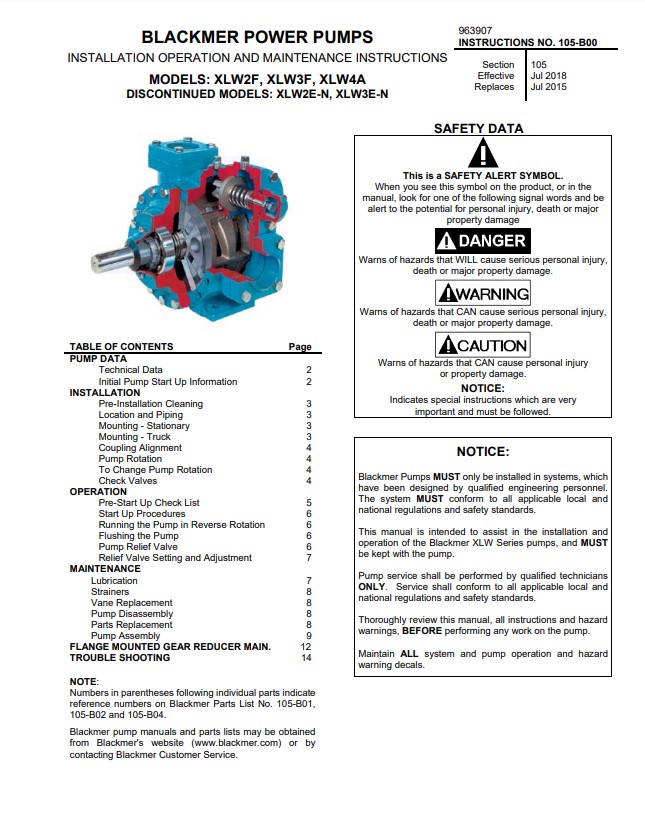

Blackmer® XLW Ductile Iron Pumps, part of the Heavy Duty Line of sliding vane pumps, are specially designed to handle liquids with suspended abrasive particles and are constructed with hardened and replaceable wear surfaces (liners and end discs) for extended service life. The XLW is capable of handling liquids with suspended particles up to 250 microns and 25% concentration.

Utilizing unique Blackmer sliding vane designs, these positive displacement rotary pumps offer the best combined characteristics of sustained high level performance, energy efficiency, trouble-free operation and low maintenance cost.

Blackmer fully Integrated Unit Assemblies are the pre-engineered and pre-designed drop-in pumping solution. These unit assemblies, include motor, gearbox, baseplate, coupling safety covers, and a XLW Sliding Vane Pump (2, 3 & 4-inch size). No alignment required with these pre-configured fully Integrated Unit Assemblies as they are ready for immediate drop-in installation.

Features and Benefits

- Replaceable casing, liners and end discs that allow easy rebuilding of the pumping chamber to like-new condition without removing the pump from the piping

- Hardened ductile-iron construction with internal relief valve

- Blackmer mechanical seal and ball bearing construction provide maximum reliability

- Symmetrical bearing support assures even loading and wear for long life

- Adjustable relief valve protects pump against excessive pressures

- External ball bearings are isolated from pumpage by mechanical seals to maximize bearing life and minimize contamination risk

Advantages of sliding vane technology:

- Unique sliding-vane pump design self-adjusts for wear to maintain flow rates

- Excellent self-priming and dry-run capabilities

- Sliding vane design provides sustained performance and trouble-free operation

- Easy maintenance: vanes can be easily replaced without removing the pump from the piping system

- High suction lift and line-stripping capabilities

- Low maintenance and low life-cycle costs

Applications

- Oxide primers

- Vertical and horizontal bead mills

- Solvent recovery

- Oil tank bottom recirculation

- Heath treater supply

- Enhanced oil recovery

- Crude or hot oil transfer

________________________________________________________________________________________________________________________

Performance and Specifications

AVAILABLE MODELS |

NOMINAL FLOW RATE |

DIFFERENTIAL PRESSURE |

|

|

|

VISCOSITY |

TEMPERATURE |

MIN/MAX SPEED (RPM) |

|

|

|

CONNECTION ORIENTATION |

VANE MATERIALS |

PRIMARY MATERIALS OF CONSTRUCTION |

|

|

|

AVAILABLE CERTIFICATES |

|

Dimensions

________________________________________________________________________________________________________________________

| PUMP MODEL | L | W | H | APPROX. WT. | |

|---|---|---|---|---|---|

| XLW2 | in | 13-4/9 | 11 | 10 | 85 lb |

| mm | 341.3 | 281 | 254 | 38.6 kg | |

| XLW3 | in | 15-15/16 | 15-7/8 | 13-3/8 | 160 lb |

| mm | 404.8 | 403.2 | 339.7 | 72.6 kg | |

| XLW4 | in | 16-7/16 | 16-15/16 | 15-7/16 | 205 lb |

| mm | 417.5 | 430.2 | 392.2 | 93 kg |

Materials of Construction

________________________________________________________________________________________________________________________

| PARTS | MATERIALS |

|---|---|

| Casing, Heads, Relief, Valve Cover | Ductile Iron: ASTM 536 |

| Liner | Hardened Ductile Iron |

Pump Options

________________________________________________________________________________________________________________________

| OPTIONS | DETAILS |

|---|---|

| ORIENTATION OPTIONS | Right Hand: INLET is to the right, when looking from driven side Left Hand: INLET is to the left, when looking from driven side |

| PORTING OPTIONS | Top Outlet: Outlet 90° offset from inlet |

| CONNECTION OPTIONS | NPT (threaded) |

| MOUNTING OPTIONS | Pump Only Unit: Pump, Motor, Baseplate, Couplings, Guards |

| SEALING OPTIONS | Blackmer single mechanical seal |

Vane Options

________________________________________________________________________________________________________________________

| MATERIAL | TEMPERATURE LIMITS | VISCOSITY |

|---|---|---|

| EC Laminate | -25°F to 300°F (-32°C to 149°C) | 105 - 15,750 cP |

| EC Hardened Iron | -25°F to 300°F (-32°C to 149°C) | 105 - 15,750cP |

Elastomer Options

________________________________________________________________________________________________________________________

| MATERIAL | TEMPERATURE LIMITS |

|---|---|

| FKM | -15°F to 300°F (-26°C to 149°C) |

| PTFE – SS Spring | 0°F to 300°F (-18°C to 149°C) |

Maintenance Kits

________________________________________________________________________________________________________________________

| MODEL(S) | DESCRIPTION | PART NUMBER | ||

|---|---|---|---|---|

| XLW2F | Kit - Maintenance | 898974 | ||

| XLW2F | Kit - Rebuild | 899074 | ||

| XLW3F | Kit - Maintenance | 898975 | ||

| XLW3F | Kit - Rebuild | 899075 | ||

| XLW4A | Kit - Maintenance | 899176 | ||

| XLW4A | Kit - Rebuild | 899276 | ||