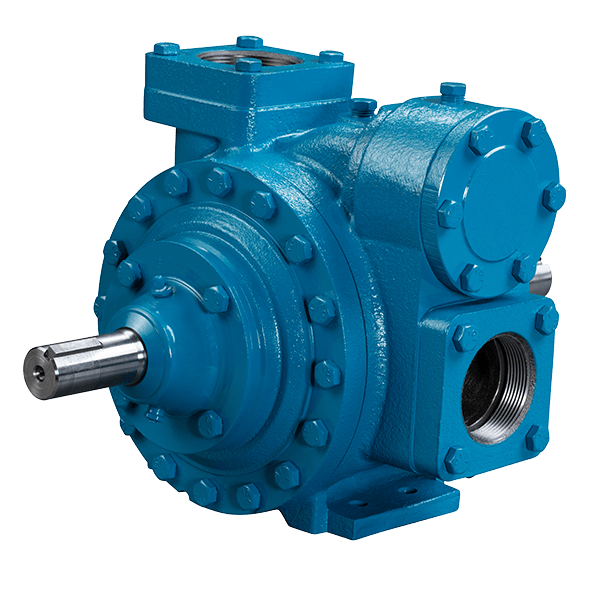

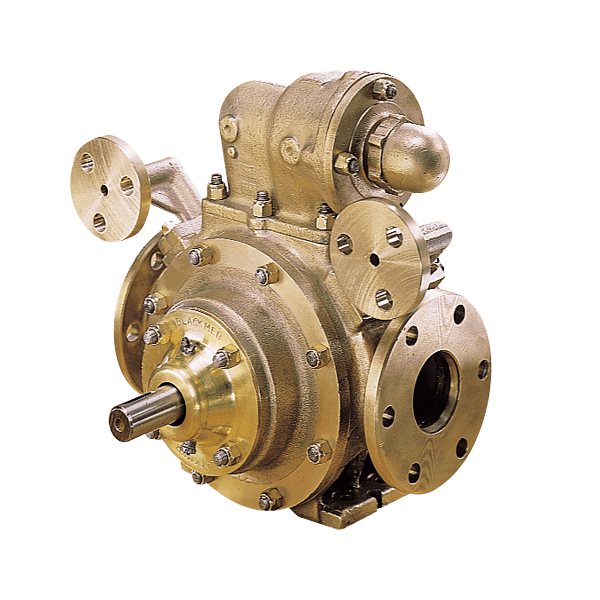

Sliding Vane Pumps

Blackmer positive displacement pumps have revolutionized the pumping industry with their unique sliding vane technology. This revolutionary rotary vane design allows the pumps to self-adjust for wear to help maintain flow rates. This sliding vane pump design creates excellent self-priming and dry-run capabilities, while also providing sustained performance and trouble-free operation.

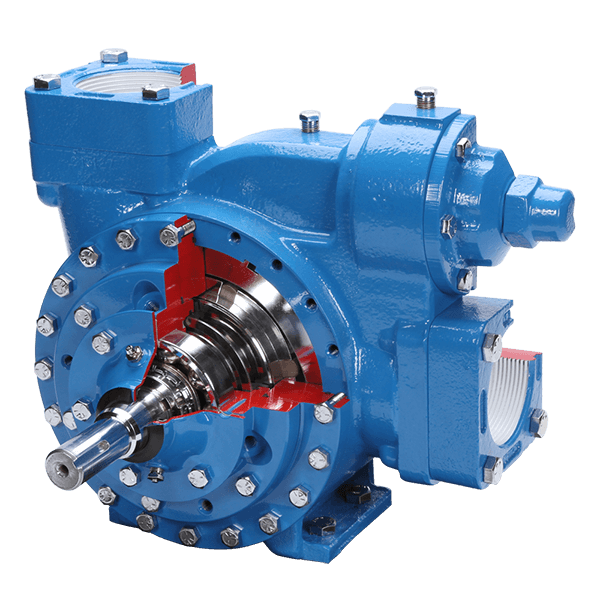

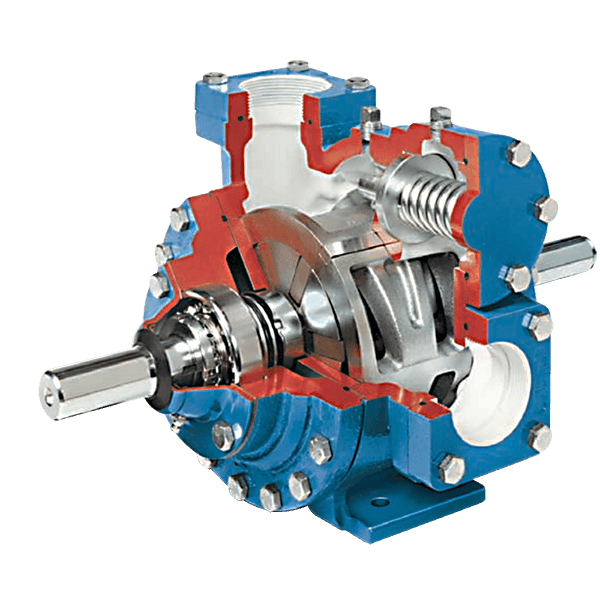

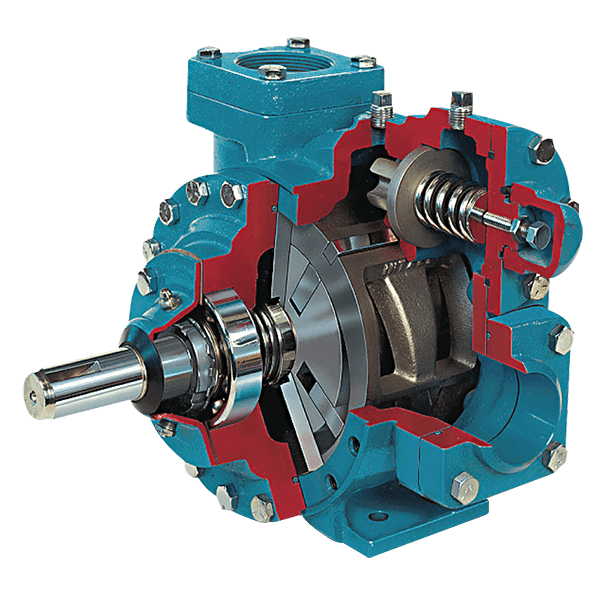

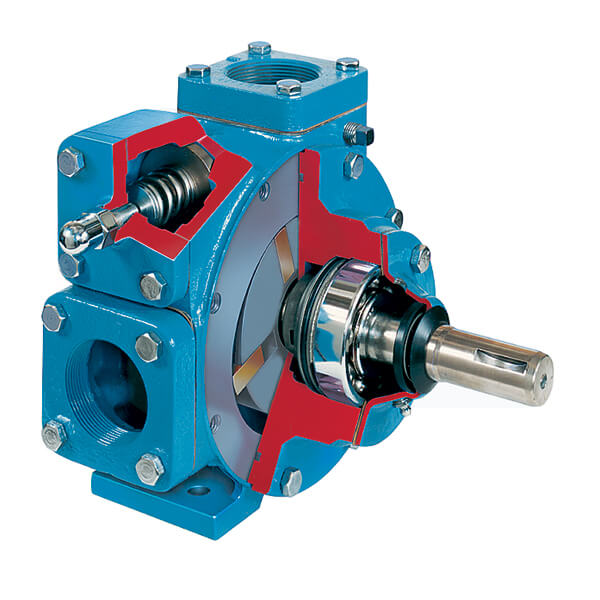

How it Works

Blackmer sliding vane pumps use a rotor with sliding vanes that draw the liquid in behind each vane, through the inlet port and into the pumping chamber. As the rotor turns, the liquid is transferred between the vanes to the outlet where it is discharged as the pumping chamber is squeezed down. Each vane provides a positive mechanical push to the liquid before it.

Vane contact with the chamber wall is maintained by three forces: (1) centrifugal force from the rotor’s rotation, (2) push rods moving between opposing pairs of vanes, and (3) liquid pressure entering through the vane grooves and acting on the rear of the vanes.

Each revolution of a Blackmer sliding vane pump displaces a constant volume of fluid. Variance in pressure has minimal effect. Energy-wasting turbulence and slippage are minimized and high volumetric efficiency is maintained.

Advantages of Sliding Vane Technology

Blackmer Sliding Vane Pumps provide numerous inherent advantages for users due to this rotary vane design, and being a positive displacement pump, among them are the following:

- Unique sliding vane pump design self-adjusts for wear to maintain flow rates

- Excellent at self-priming, eliminates expensive priming systems

- Extended dry-run capability, eliminates nuisance current monitoring systems

- Sliding vane design provides sustained performance and trouble-free operation

- Easy maintenance: vanes can be easily replaced without removing the pump from the piping system

- High suction lift abilities that exceed 25 feet (7.6 meters) and line-stripping capabilities to completely empty tanks, and piping of fluid

- Low maintenance and low life-cycle costs, pumps are renewable and repairable

- Solids handling, provided by large displacement and slow internal velocities

- Thin to thick fluid viscosity flexibility, eliminates expensive heating systems

- Highly efficient, sliding vane pumps require less horsepower than other pumps, meaning spending less on motors initially and less on electricity to power the pump

Cavitation Line

Rotary vane pumps used for high vapor pressure liquids

______________________________________________________________________________________________________________

|

|

|

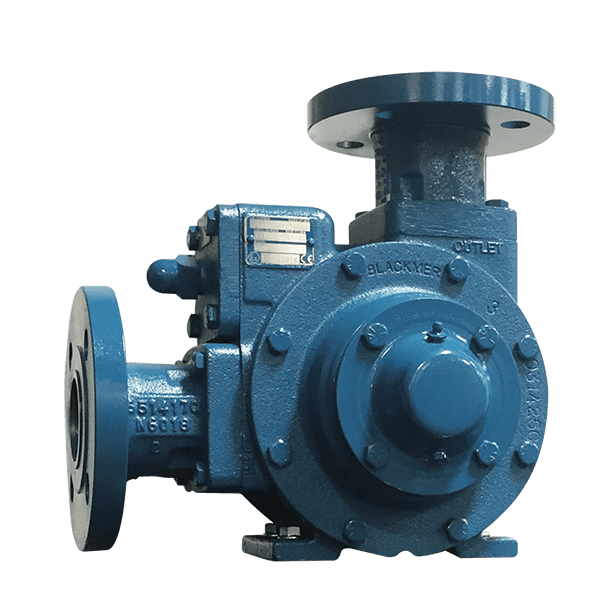

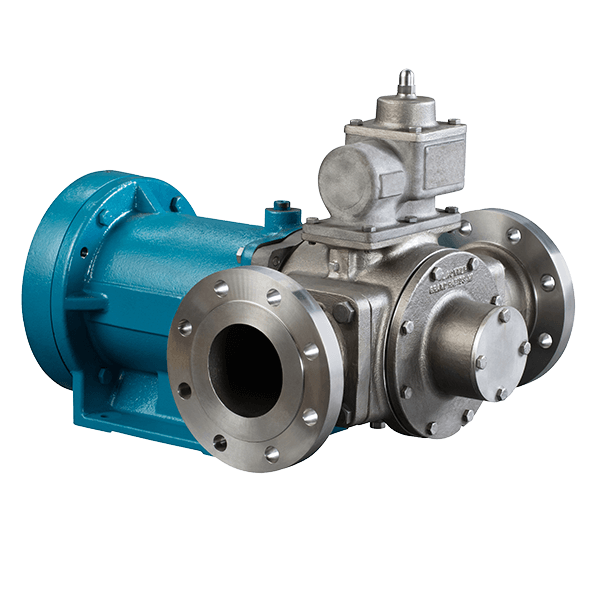

| LGL Series Sliding Vane Pumps | SGL Series Sliding Vane Pumps | CRL Series Sliding Vane Pumps |

| Rotary vane pumps designed specifically for propane (LPG) and NH3 applications | Ductile-iron rotary vane pumps for liquefied gas transfer applications | Ductile-iron, recirculation vane pumps for liquefied CO2 applications |

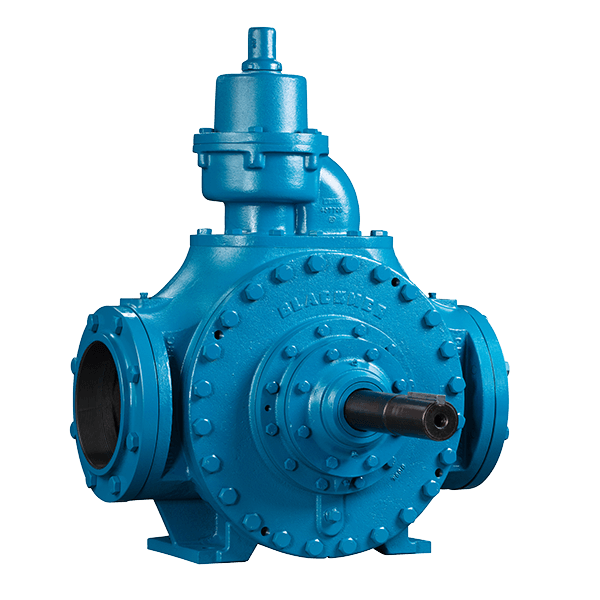

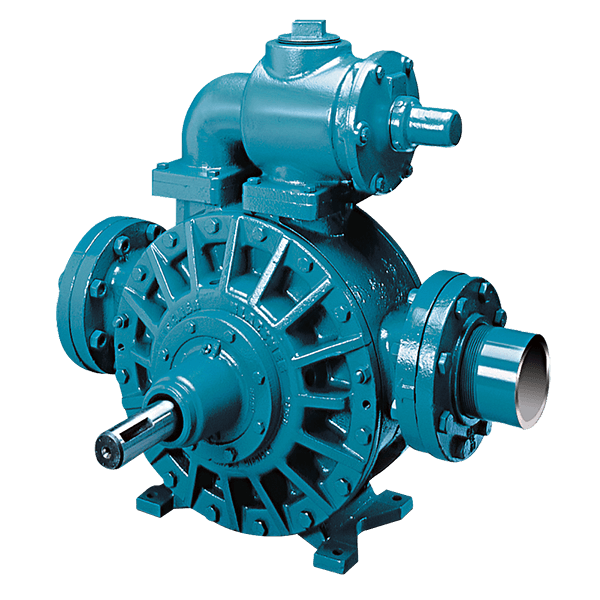

Heavy Duty Line

Rotary vane pumps used for severe-duty high volume transfer

________________________________________________________________________________________________________________________

|

|

|

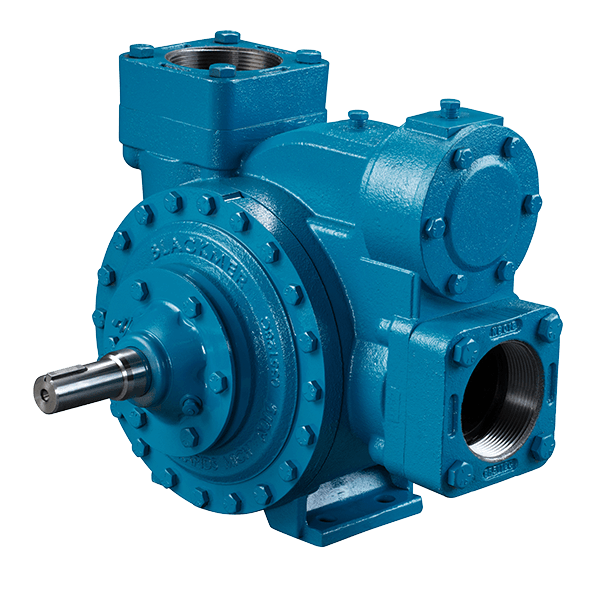

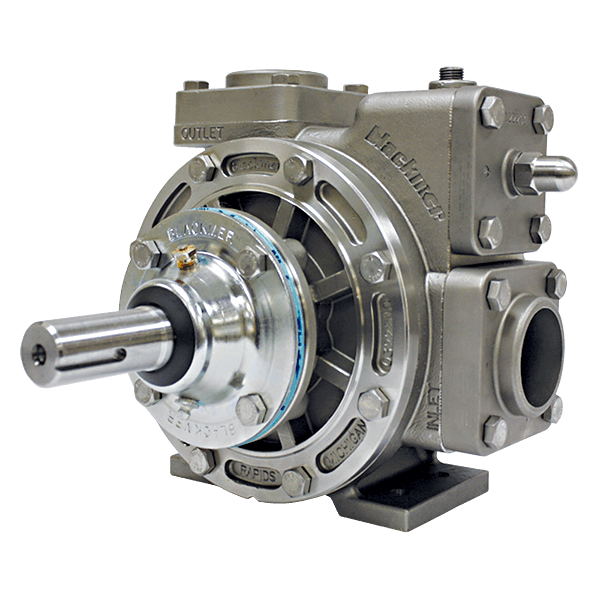

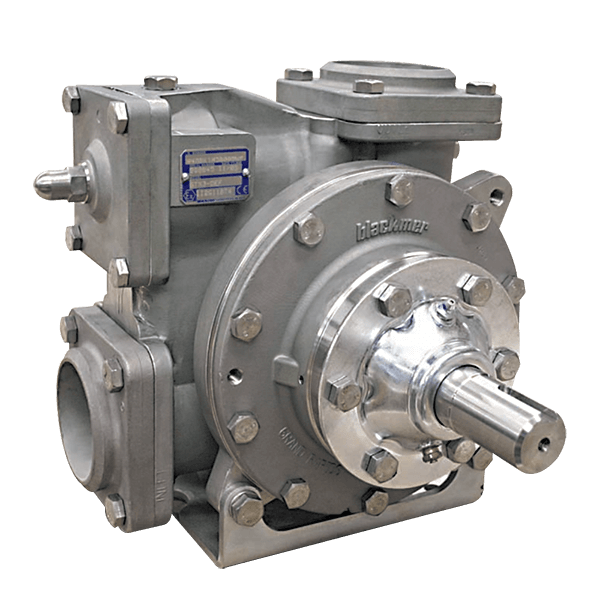

| HXL Series Sliding Vane Pumps | ML Series Sliding Vane Pumps | XLW Series Sliding Vane Pumps |

| Positive displacement vane pumps for use in refineries, terminal operations, and loading applications | Ductile-iron rotary vane pumps designed for handling all types of liquids | Ductile-iron rotary vane pumps capable of handling liquids with suspended particles |

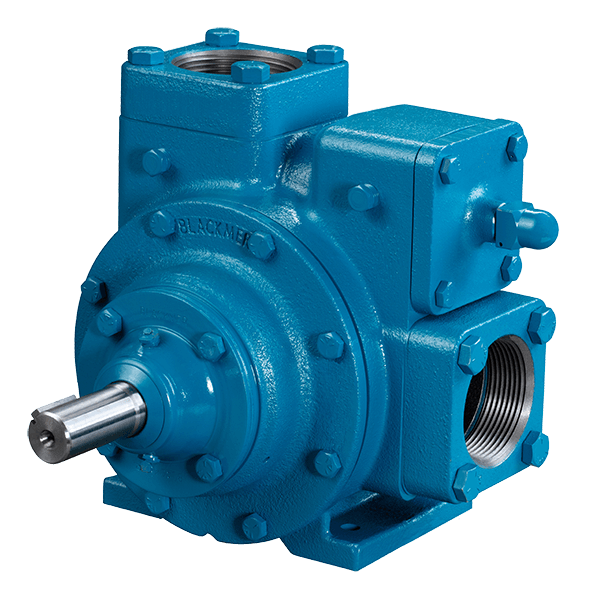

Iron Line

Rotary vane pumps used for non-corrosive liquids of all viscosities

________________________________________________________________________________________________________________________

|

|

|

|

|

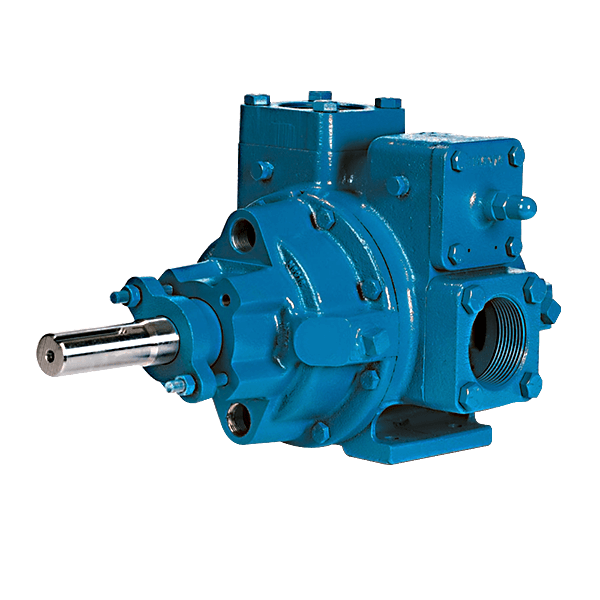

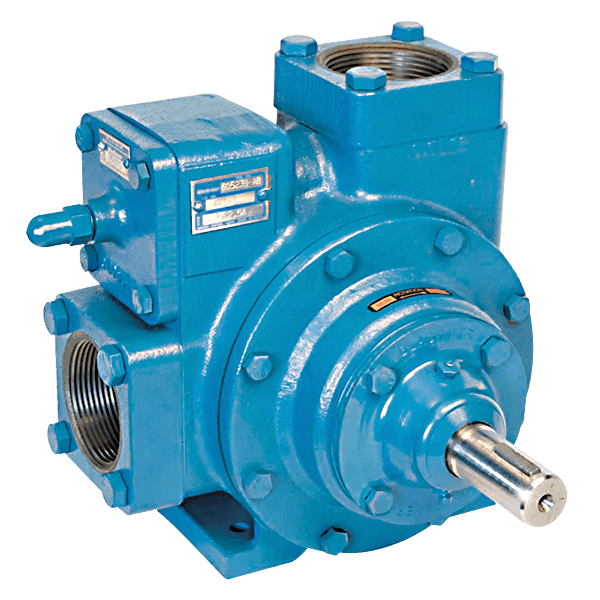

| TX Series Sliding Vane Pumps | X Series Sliding Vane Pumps | GNX Series Sliding Vane Pumps | XL Series Sliding Vane Pumps | NP Series Sliding Vane Pumps |

| Durable vane pumps utilized for the transport of various chemicals and fuels | Ductile-iron rotary vane pump designed for the blending, loading, unloading & transfer of various substances | Alignment-free reduced-speed positive displacement pump for non-corrosive liquids and petroleum products | Ductile-iron rotary vane pumps used in processing, filling and transfer applications | General purpose positive displacement pumps ideal for handling a wide variety of clean non-corrosive liquids |

Magnetic Line

Positive displacement rotary vane pumps that use a magnetic drive without dynamic seals

________________________________________________________________________________________________________________________

|

|

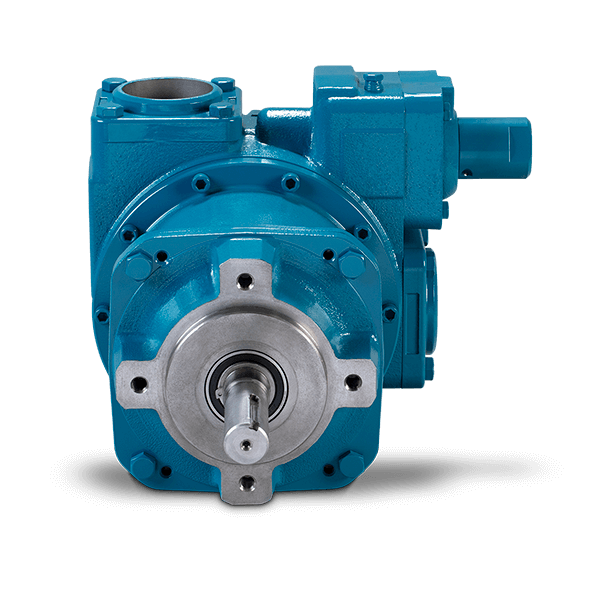

| MAGNES Series Sliding Vane Magnetic Drive Pumps | SMVP Series Sliding Vane Pumps |

| Magnetic drive pumps that provide a leak-free pumping solution for difficult to seal liquids | Stainless-steel vane pumps with a seal-less magnetic coupling for a durable, leak-free operation |

Stainless Line

Rotary vane pumps used for corrosive liquids with thin viscosity

________________________________________________________________________________________________________________________

|

|

|

|

SNP Series Sliding Vane Pumps |

STX Series Sliding Vane Pumps |

SX Series Sliding Vane Pumps |

| Stainless-steel rotary vane pumps for caustic or corrosive liquids | Stainless-steel vane pumps designed for fast fluid off-loading | Stainless-steel vane pumps for use in corrosive, low- and medium-viscosity process applications |

Specialty Line

Rotary vane pumps used in applications where unique pumping requirements are present

________________________________________________________________________________________________________________________

|

|

|

| Sliding Vane Hand Pumps | Dispensing Sliding Vane Pumps | Military Sliding Vane Pumps |

| Hand-operated vane pumps designed for easy, efficient operation in handling a wide range of liquids | Power-operated vane pumps for petroleum product dispensing systems | Durable sliding vane pumps trusted by militaries around the world |