Your Seal-less, Leak-Free Blackmer Magnetic Drive Pump

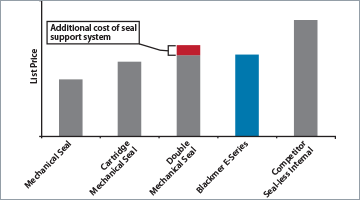

Elevate your pump performance to new heights with Blackmer's E Series Magnetic Drive Gear Pumps. These pumps are not just innovative, durable, and environmentally friendly; they represent a significant advancement in pump technology. The E Series is engineered to outshine its competitors, thanks to a groundbreaking design featuring a patented between-the-bearing support system. This unique configuration effectively eliminates leaks and minimizes mechanical wear, enhancing both the safety of your personnel and environmental protection.

Furthermore, the E Series offers a range of material construction options, including ductile iron, carbon steel, and stainless steel, ensuring compatibility with a wide array of chemicals. Notably, when it comes to cost-effectiveness, reliability, and initial investment, no other magnetically coupled pump can match the E Series Magnetic Drive Gear Pump.

| Available Materials: | Capacity: |

|

|

| Max Temperature: | Max Pressure: |

|

|

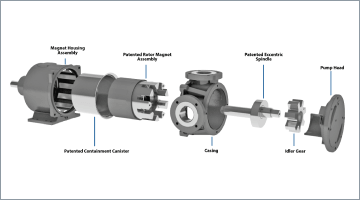

Blackmer E Series Magnetic Drive Gear Pump Features

|

|

|

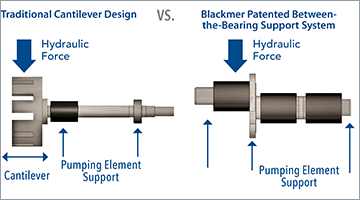

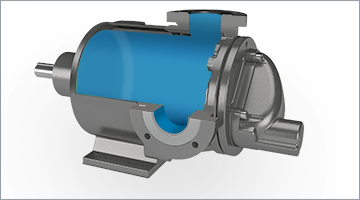

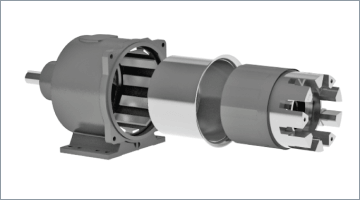

| Between-the-Bearing Support System | One Fluid Chamber Design | High-Torque and Compact Magnetic Coupling |

| Eliminates the damaging effects of cantilevered loads that are present in competitor internal gear pumps, maximizing rotor, idler and bushing life. | Greatly improves fluid circulation through the magnetic coupling, resulting in lower operating temperatures, longer magnet life, and more effective cleaning and flushing processes. | High-strength magnetic couplings are standard to allow for more operational flexibility, with inner magnets mounted directly to the rotor for an extremely compact design. |

|

|

|

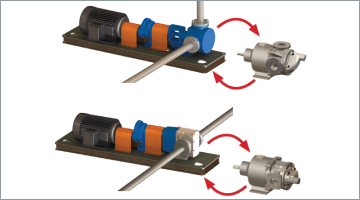

| Simple Design | Competitor Pump Interchangeability | Affordable Upfront Solution |

| The need for only seven primary components improves reliability and reduces system complexity while easing maintenance and repair. | Interchangeable with up to 95% of the packed, mechanically sealed and seal-less magnetic drive gear pumps in use today, with no need for piping, driver, baseplate or coupling modifications. | Due to the simple, seven primary-component part design, E Series Magnetic Drive Gear Pumps have a much lower investment cost than competitors’ magnetic drive gear pumps. |

Blackmer E Series Magnetic Drive Gear Pump Specifications & Performance

| MODEL | DUCTILE IRON GEAR PUMP PORT SIZES | CARBON STEEL GEAR PUMP PORT SIZES¹ | STAINLESS STEEL GEAR PUMP PORT SIZES¹ | |||

|---|---|---|---|---|---|---|

| THREADED | FLANGED | THREADED | FLANGED | THREADED | FLANGED | |

| E1-2 E1-4 |

N/A | N/A | 1-1/2" NPT 1-1/2" BSPT |

1-1/2" ANSI 2" ANSI DN40 |

1-1/2" NPT 1-1/2" BSPT |

1-1/2" ANSI 2" ANSI DN40 |

| E1-24 E1-32 |

2" NPT 2" BSPT |

2" ANSI 2" ANSI 180° |

2" NPT 2" BSPT |

2" ANSI 2" ANSI 180° 3" ANSI |

2" NPT 2" BSPT |

2" ANSI 2" ANSI 180° 3" ANSI DN50 |

| E1-55 E1-69 E1-82 |

N/A | 3" ANSI 4" ANSI |

N/A | 3" ANSI 4" ANSI DN80 |

N/A | 3" ANSI 3" ANSI 180° 4" ANSI DN80 |

| E1-133 | N/A | 4" ANSI² | N/A | 4" ANSI | N/A | 4" ANSI |

| E1-222 | N/A | 6" ANSI² 180° | N/A | 6" ANSI 180° | N/A | 6" ANSI 180° |

(1) Flanged connections meet Class 150# ANSI

(2) Flanged connections meet Class 125# ANSI

Note: All port orientations 90° unless specifically noted 180°

Note: All E Series ANSI flanges are "raised-face" (RF), with the exception of E1-133/222 models which are "flat-face" (FF)

| MODEL | DUCTILE IRON / CARBON STEEL GEAR PUMPS | STAINLESS STEEL GEAR PUMPS | ||

|---|---|---|---|---|

| RPM | GPM (M³/H) | RPM | GPM (M³/H) | |

| E1-2 | 1,750 | 15 (3.4) | 1,150 | 10 (2.3) |

| E1-4 | 1,750 | 30 (6.8) | 1,150 | 20 (4.5) |

| E1-24 | 780 | 75 (17.0) | 640 | 55 (12.5) |

| E1-32 | 780 | 100 (22.7) | 640 | 80 (18.2) |

| E1-55 | 640 | 135 (30.7) | 520 | 110 (25.0) |

| E1-69 | 640 | 170 (38.6) | 520 | 140 (31.8) |

| E1-82 | 640 | 200 (45.4) | 520 | 160 (36.3) |

| E1-133 | 520 | 300 (68.1) | 520 | 300 (68.1) |

| E1-222 | 520 | 500 (113.6) | 520 | 500 (113.6) |