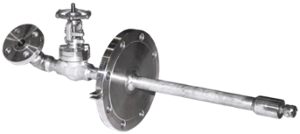

Internal Mix, Siphon-Fed Round Pneumatic Spray Nozzles

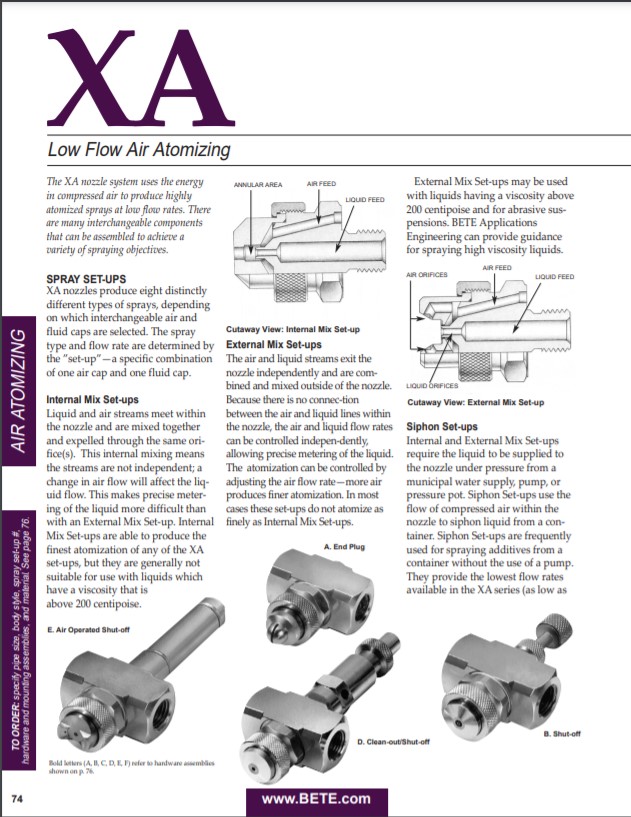

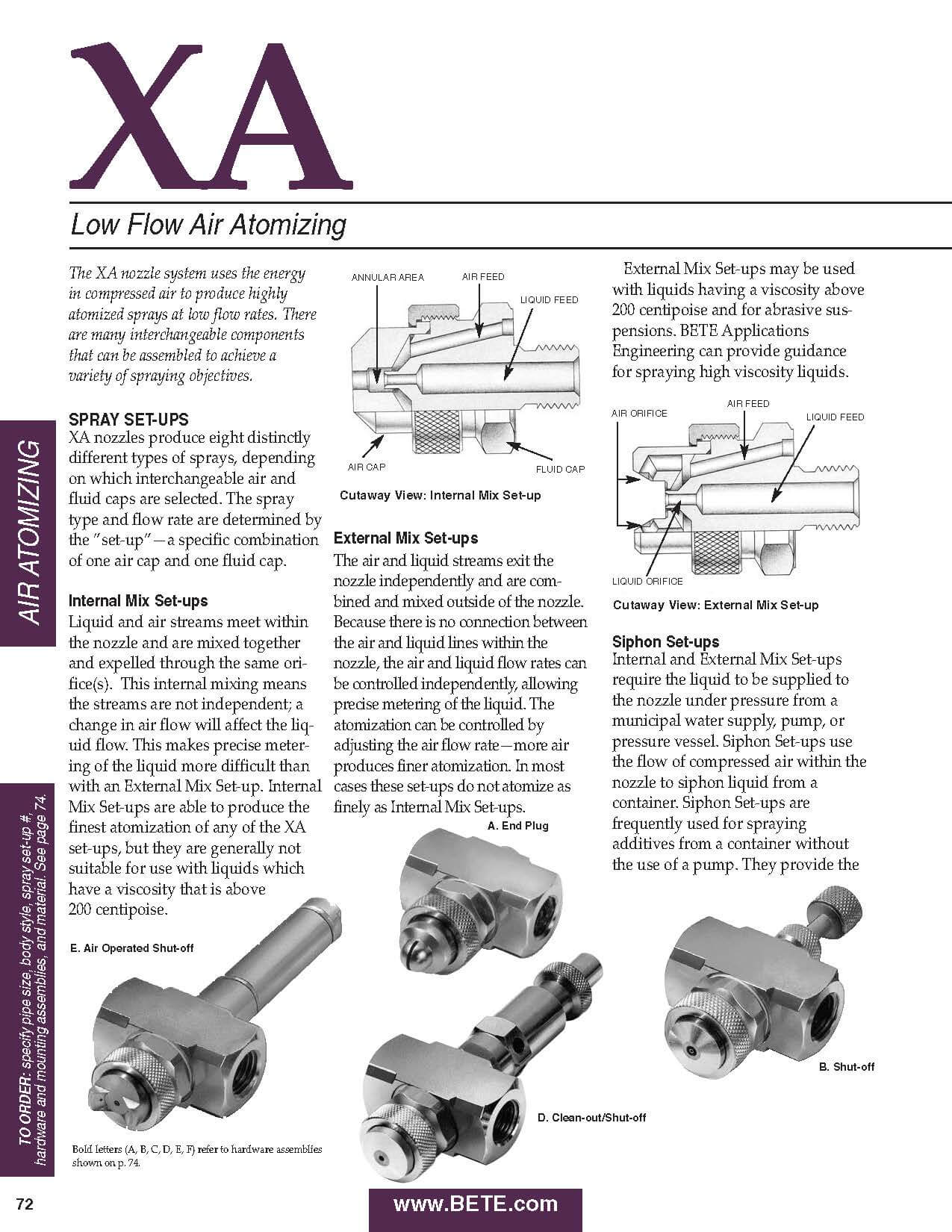

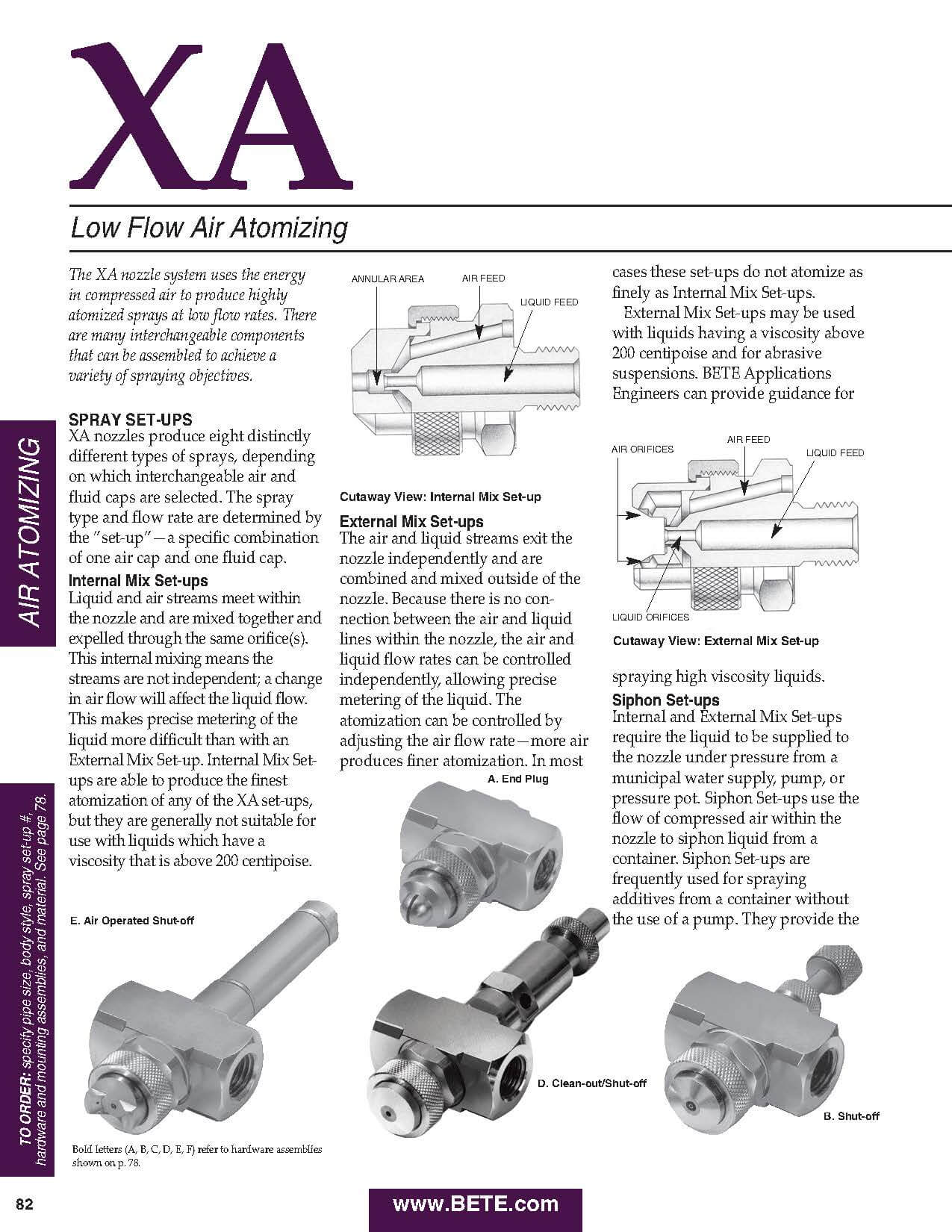

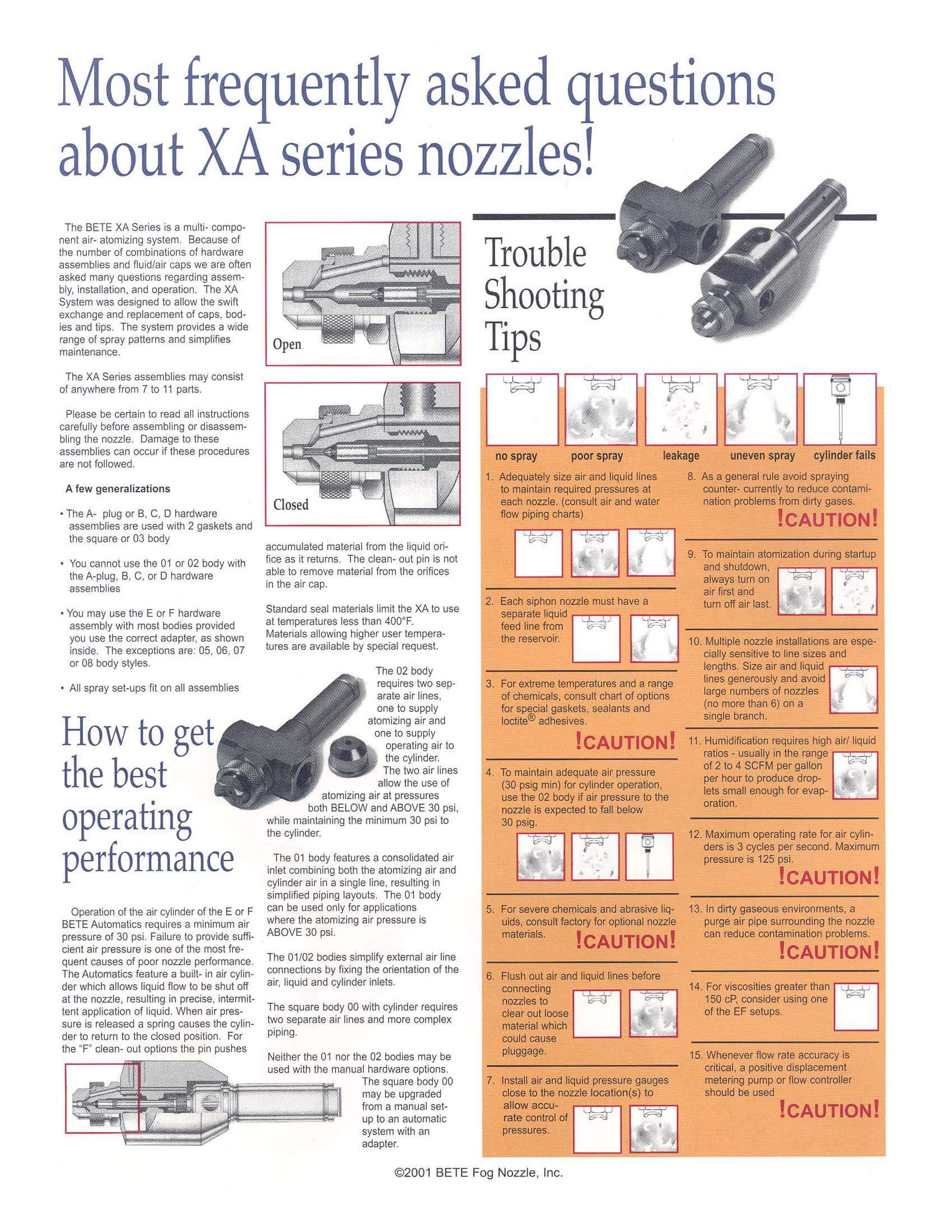

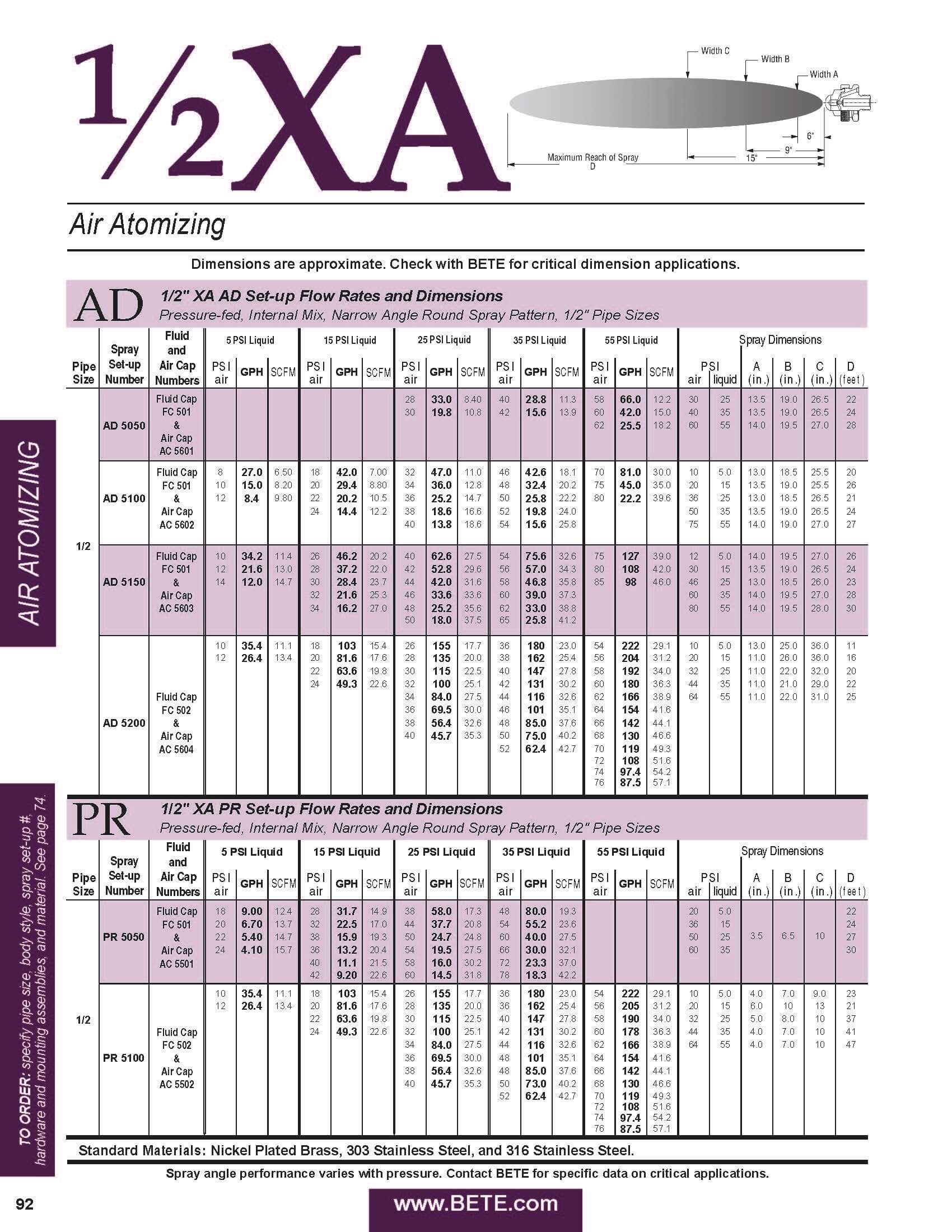

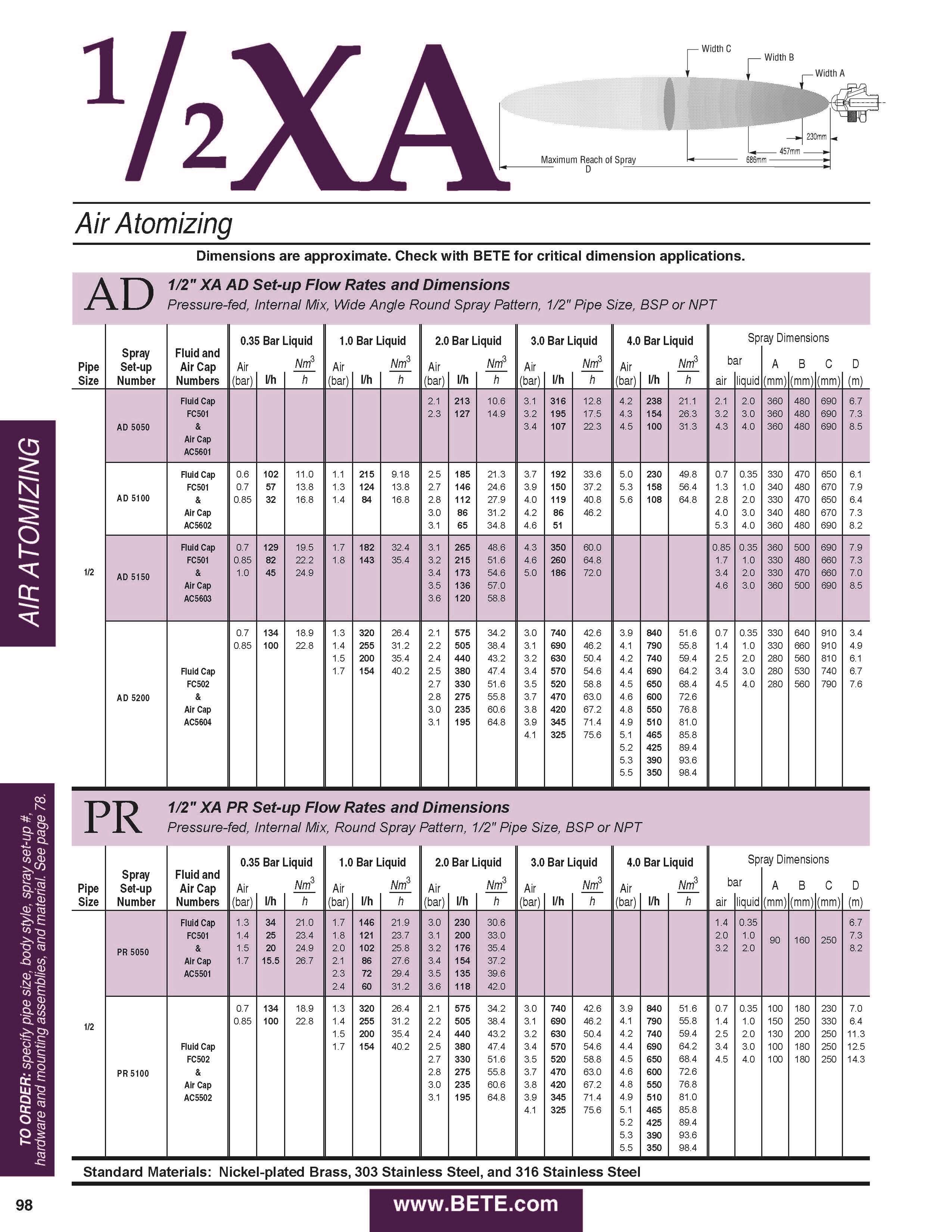

John Brooks Company carries a complete range of two-fluid (typically compressed air & water) atomizing BETE Spray Nozzles. The BETE XASR spray nozzle is part of the BETE XA Nozzle system. It uses the energy in compressed air to produce highly atomized sprays at low flow rates. There are many interchangeable parts that can be assembled to achieve a variety of spraying objective. The BETE XA nozzles produce eight distinctly different types of sprays, depending on which interchangeable air and fluid caps are selected.

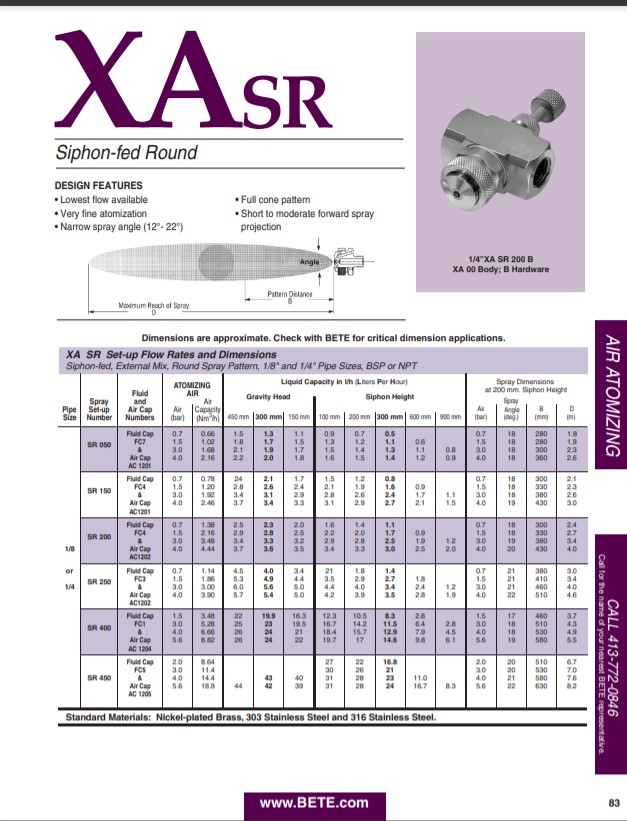

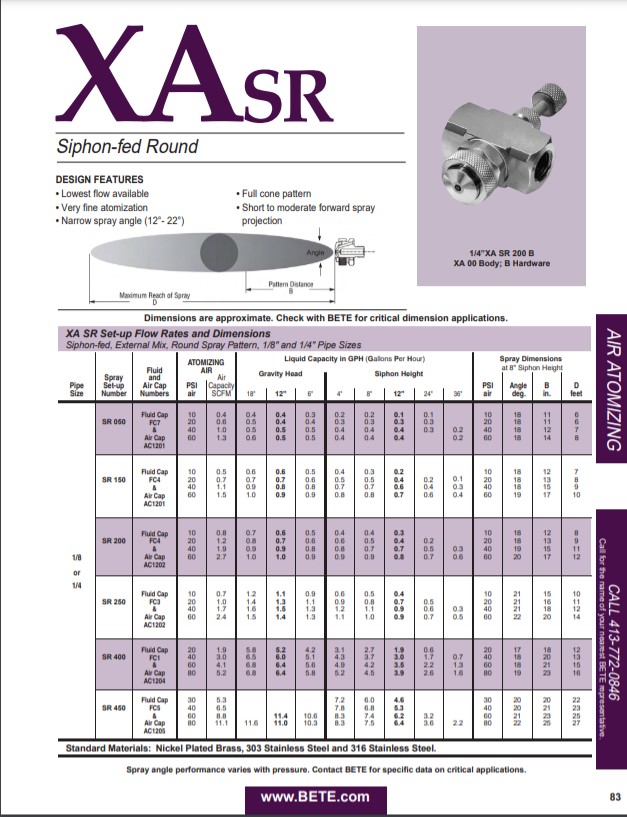

Design Features of BETE XASR Spray Nozzles

- Lowest flow available

- Very fine atomization

- Narrow spray angle (12° to 22°)

- Full cone pattern

- Short to moderate forward spray projection

BETE XASR Spray Patterns

- Full Cone Spray Nozzles

- Air Atomizing Spray Nozzles

How Spray Pattern is Achieved

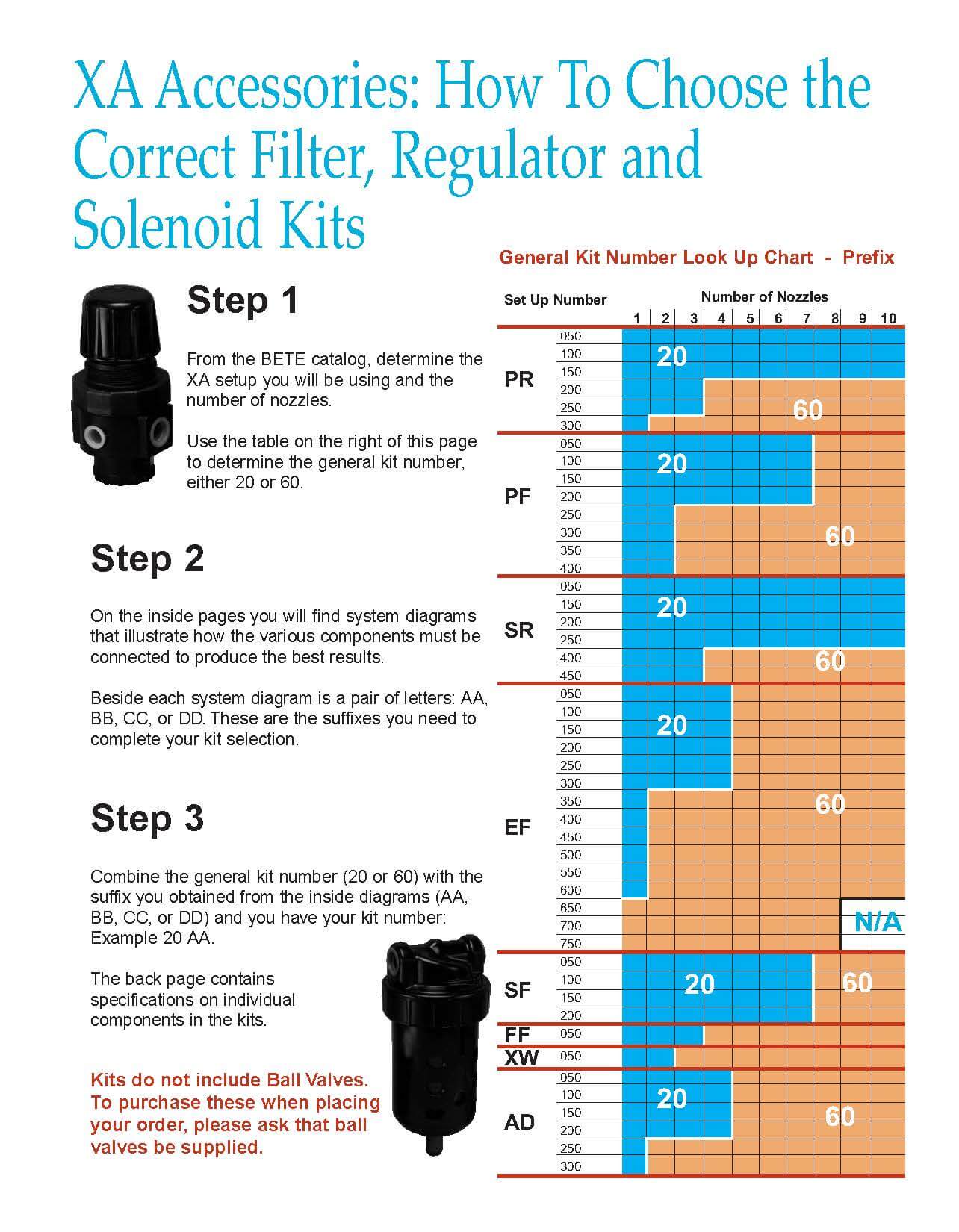

- The liquid is supplied by either a siphon or gravity feed in a siphon-fed system. An air regulator controls the air delivery pressure, while the air filter ensures high-quality compressed air. Maintaining operational control by manual or solenoid valves used with various hardware assemblies.

- Liquid and air streams combine inside the nozzle and are mixed. They exit through the same orifice creating a narrow full cone spray angle

- The streams are not independent; Liquid flow is affected as airflow changes.

Applications for BETE XASR Spray Nozzles

- Air Atomizing

- Air Conditioning

- Coating

- Concrete Curing

- Cooling: Evaporative

- Fogging

- Humidification (humidify air in ducts, drying kilns, curing rooms, greenhouses, and other open areas.)

- Lubrication (lubricate dies and moulds, roll bite in strip mills)

- Misting

- Moistening

- Odor Control

- Scrubbing: Conditioning (inject ammonia or water upstream of electrostatic precipitators; inject odor control additives)

- Scrubbing: Dry (inject lime slurry into dry scrubber)

The photo on this page represents only one of the configurations available. Please contact us for more information.