BETE Clog-Resistant Tangential Spray Nozzles

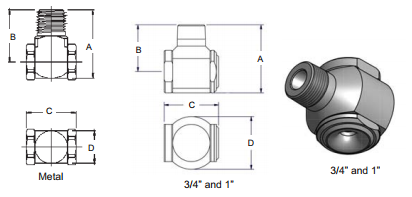

The BETE WTZ Spray Nozzle is a full cone tangential whirl nozzle. With this design of nozzle the fluid is initially in motion perpendicular to the final spray direction. The fluid travels down the pipe, enters tangentially into the nozzle body and is twisted through 90 degrees in a whirl motion causing it to break up into droplets before exiting the spray orifice. Normally the whirl motion of these nozzles causes the spray to exit in a hollow cone pattern, but with the addition of a contoured insert fluid can be drawn to the center as well forming a full cone pattern.

A tangential nozzle may also be selected over an axial whirl nozzle due to space considerations. For example, if a lance is being put into a gas stream the spray would need to be perpendicular to the initial fluid flows.

Furthermore, the design is naturally more resistant to clogging than axial whirls as the whirl chamber is less intricate.

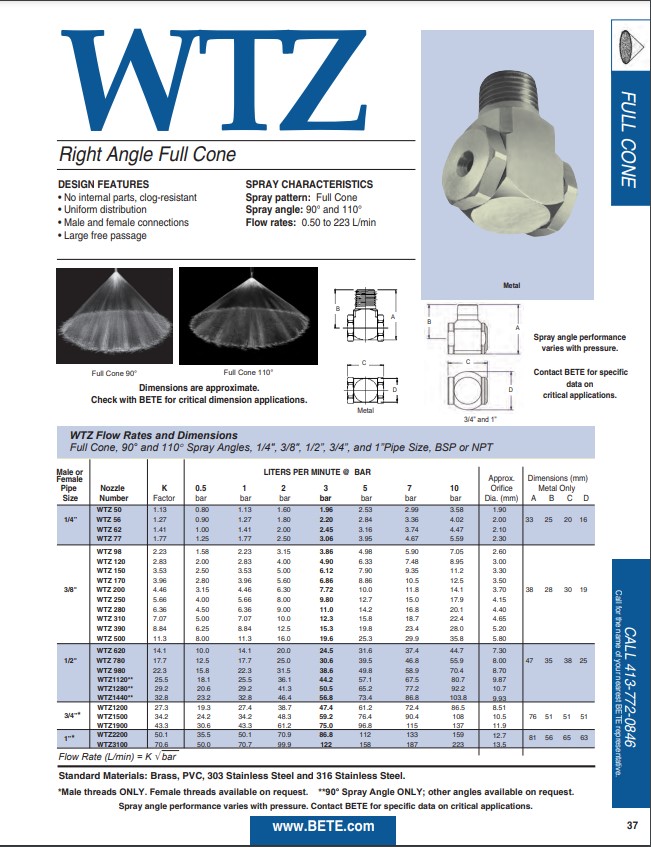

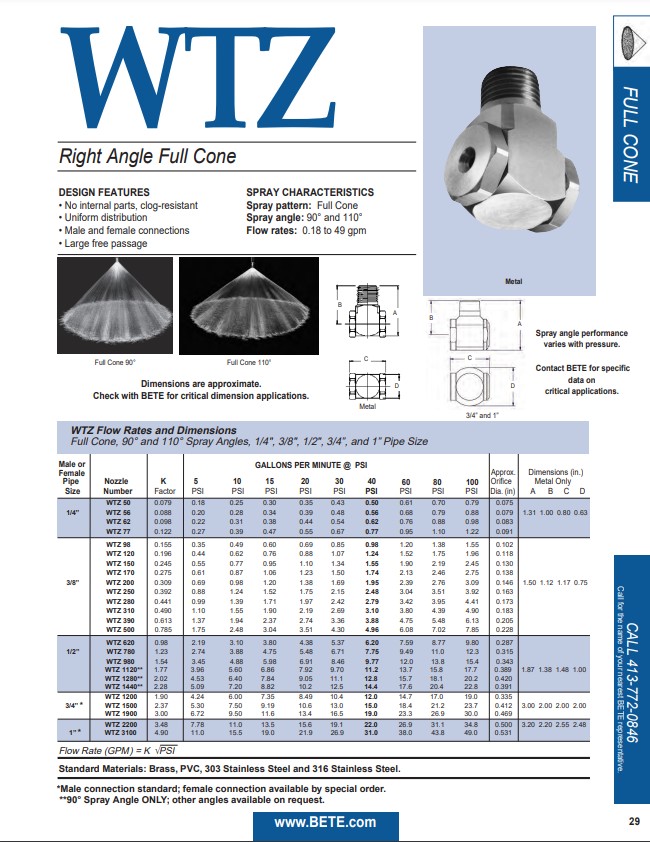

Design Features of BETE WTZ Spray Nozzles

- No internal parts, clog-resistant

- Uniform distribution

- Male and female connections

- Large free passage

| Available Spray Angles | Flow Rate Range |

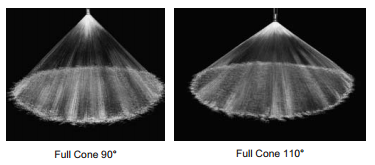

| 90 - 110° | 0.177 to 49 gpm |

| Available Connection Types | Materials |

|

PVC, Brass, 303, 316, Duplex 2205, Nickel Alloy C-276, Nickel Alloy C-22, Nickel Alloy 625, Nickel Alloy 825 |

Spray Patterns: Full Cone

Standard Materials: Brass, PVC, 303 Stainless Steel and 316 Stainless Steel

BETE WTZ Spray Nozzle Applications

- Clog-resistance