Axial Spray Nozzles With Low Flow Rates

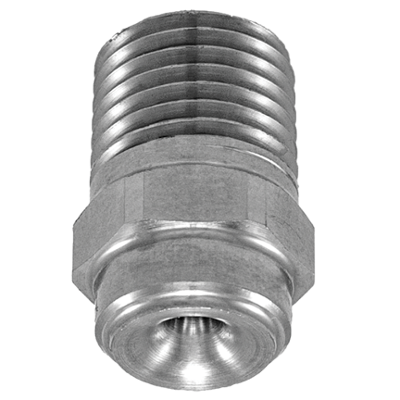

The BETE whirl nozzles provide uniform distribution of relatively large droplets. Tangential or axial whirl nozzles feature an internal vane within the nozzle body which causes the liquid to “whirl”. The BETE WL Whirl Nozzle is an axial full cone whirl nozzle. With this design of full cone nozzle the fluid is set into a whirl motion by an internal vein or whirl chamber. The resulting turbulence breaks up the liquid into droplets which are then shaped in to a full cone pattern as they exit the orifice.

Design Features of BETE WL Full Cone Nozzles

- Advanced whirl plate design produces uniform coverage

- Male and female connections

- Low Flow

BETE WL Nozzles Spray Characteristics

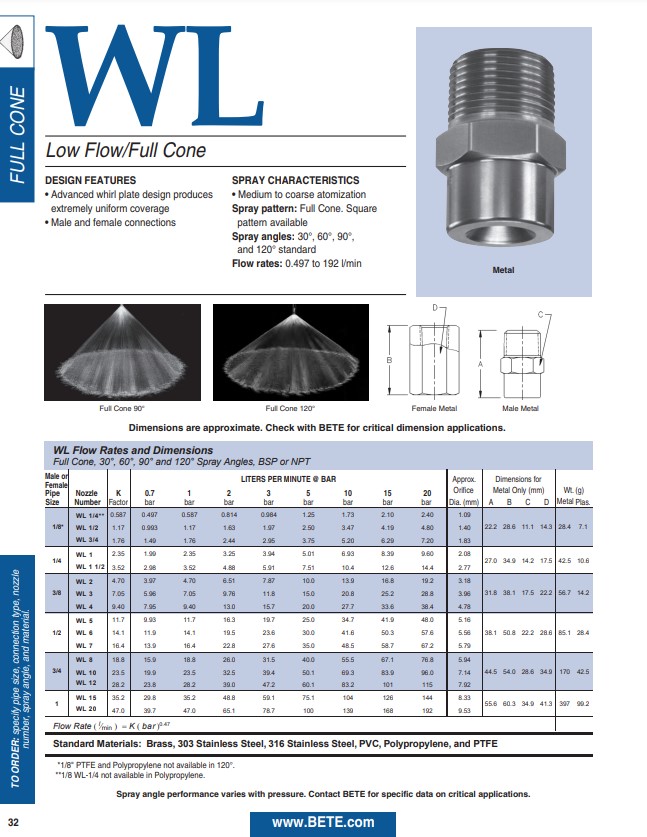

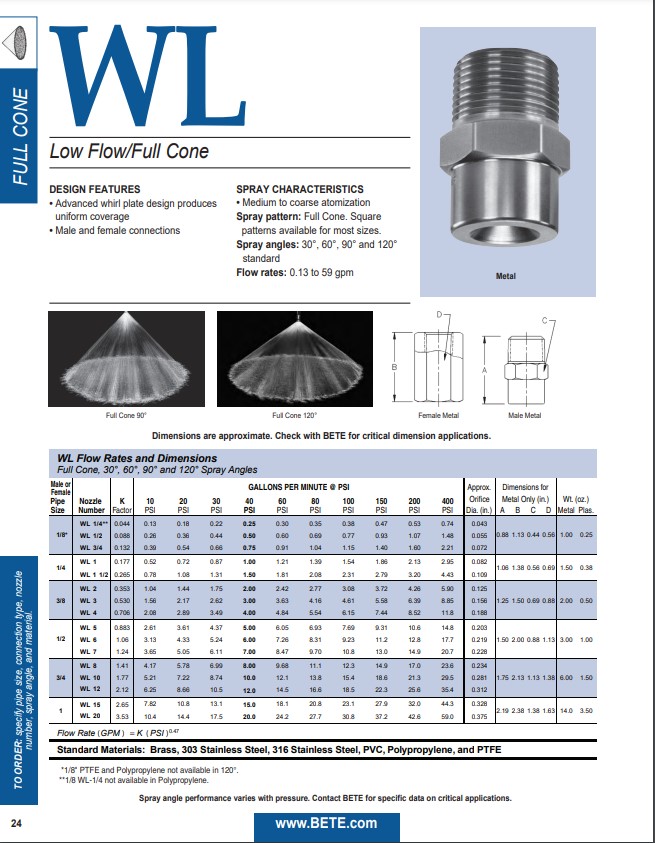

- Medium to coarse atomization

-

Spray pattern: Full Cone. Square pattern available

| Available Spray Angles | Flow Rate Range |

| 30 - 120° | 0.0937 to 65.5 gpm |

| Available Connection Types | Materials |

|

PVC, PTFE, CPVC, Brass, 303, 316, Duplex 2205, Nickel Alloy C-276, Nickel Alloy C-22, Nickel Alloy 625, Nickel Alloy 825, Polypropylene, PVDF |

Applications of BETE WL Full Cone Nozzles

- Cooling: Deluge

- Cooling: Parts

- Distribution

- Etching: Electronics

- Foam Control

- Mist Eliminator Wash

- Packing

- Washing: Intermittent

- Washing: Parts

How Spray Pattern is Achieved on BETE WL Nozzles

- Atomization is achieved by the water spun inside the nozzle and exiting an orifice

- Produces medium to coarse droplet size

- More uniform pattern than spiral nozzles