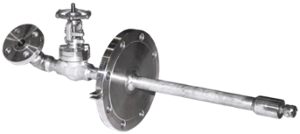

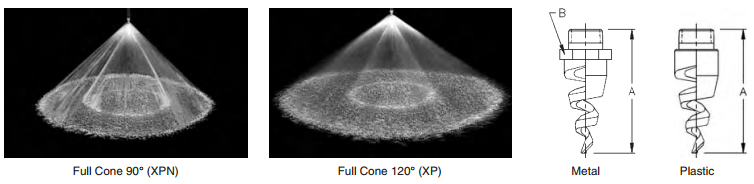

BETE Clog-Resistant Full Cone Pigtail Nozzles

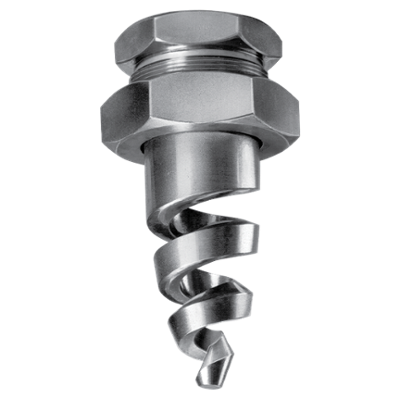

The BETE spiral spray pattern remains one of the major advances in nozzle technology. The liquid is atomized into small droplets by a continuously descending spiral and, therefore, enters and exits with no internal restrictions through relatively large passages. the result is higher discharge velocity so lower pumping pressures can be used to produce the required atomization. The spiral full cone pattern and is developed from a series of concentric hollow cones that combine to give a full cone effect.

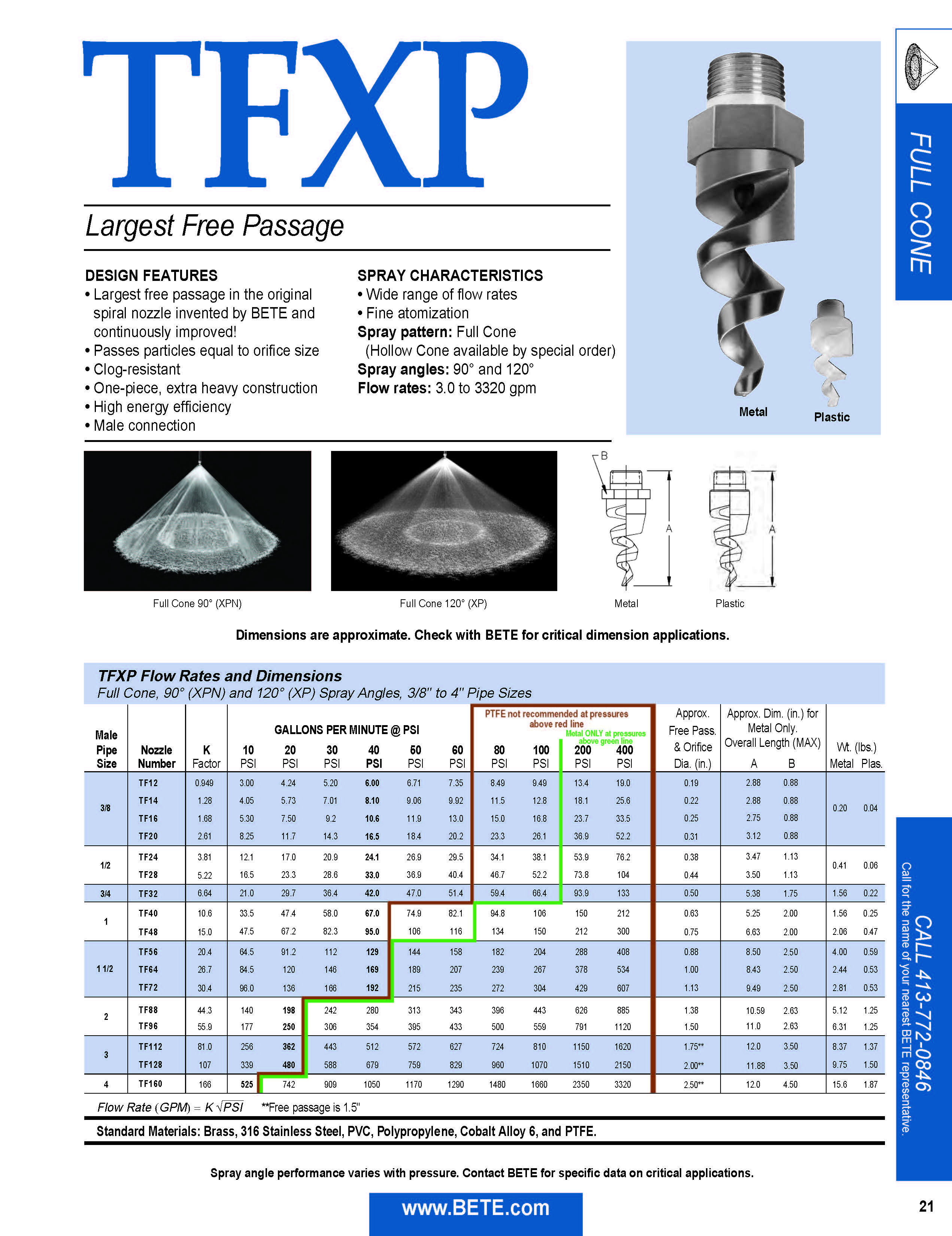

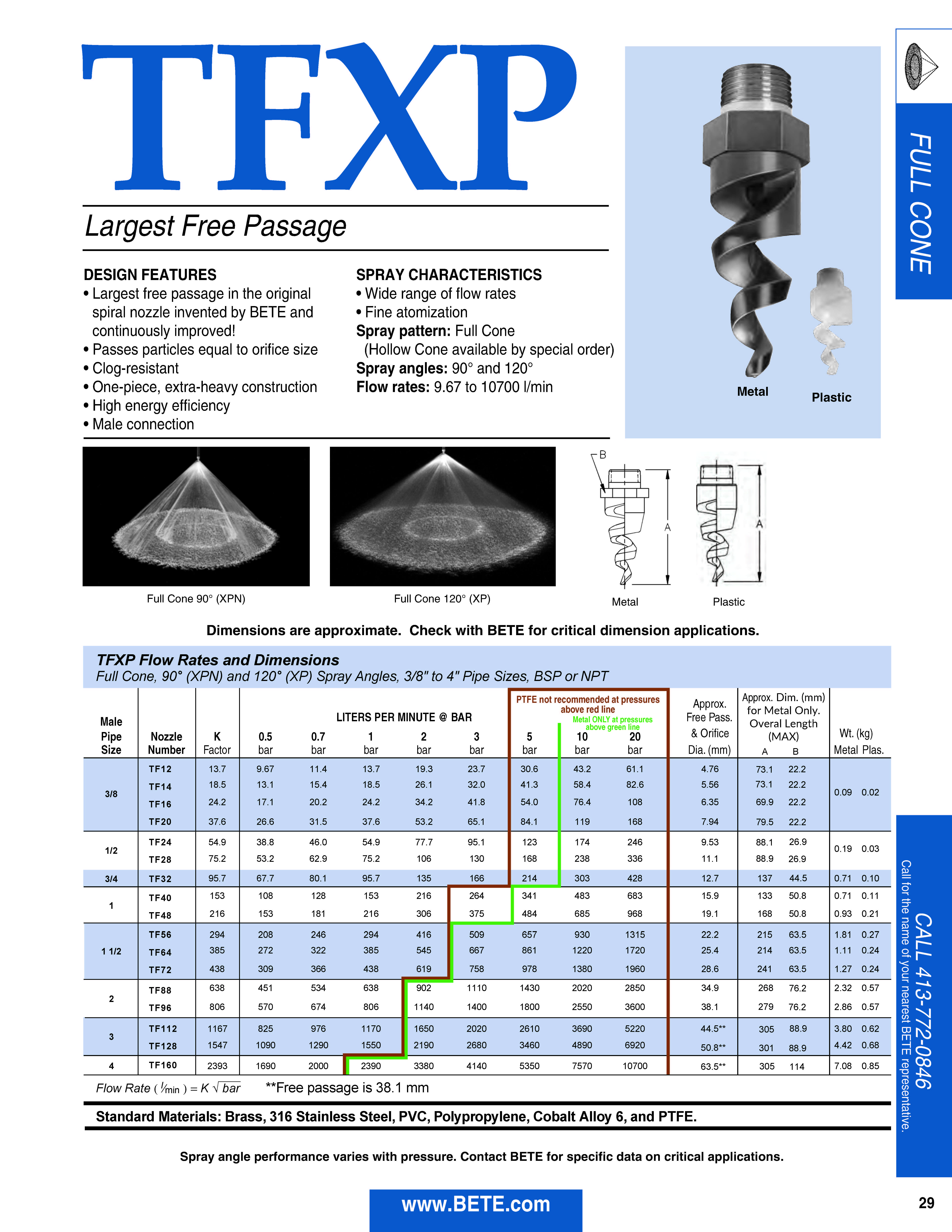

BETE TFXP Spray Nozzles Design Features

- Large free passage in the original spiral nozzle invented by BETE and continuously improved!

- Passes particles equal to orifice size

- Clog-resistant

- One-piece, extra heavy construction

- High energy efficiency

- Male connection

- Largest free passage design

- Fine atomization

BETE TFXP Spray Characteristics

- Wide range of flow rates

- Fine atomization

- Clog resistant

| Available Spray Angles | Flow Rate Range |

| 90 - 120° | 2.12 to 3710 gpm |

| Available Connection Types | Materials |

|

Brass, 316, 310, 347, Cobalt Alloy 6, Duplex 2205, A494 CW6MC (cast Nickel Alloy 625), A494 CW2M (cast Nickel Alloy C-276), A494 CX2MW (cast Nickel Alloy C-22), A494 CU5MCuC (cast Nickel Alloy 825), Nickel Aluminum Bronze, PVC, Polypropylene, CPVC, PVDF, PTFE |

- Spray Patterns: Full Cone (Hollow Cone available by special order)

How Spray Pattern is Achieved for BETE TXFP Spray Nozzles

The spray pattern of the spiral nozzle is formed by the fluid shearing along with the turns of the spiral, which produce multiple concentric cones. These cones form 2 to 3 bands of relatively coarse droplets surrounded by wider bands of relatively fine droplets.