In various applications, maintaining a well-mixed or agitated tank is essential. The traditional approach involves mechanical mixing components like a motor-driven impeller. However, many scenarios, especially those involving immiscible liquids or suspended solids, can achieve effective mixing with a pump and submerged spray nozzles. This approach significantly reduces system complexity, capital costs, and maintenance demands.

Efficient Tank Mixing with BETE TurboMix Nozzles

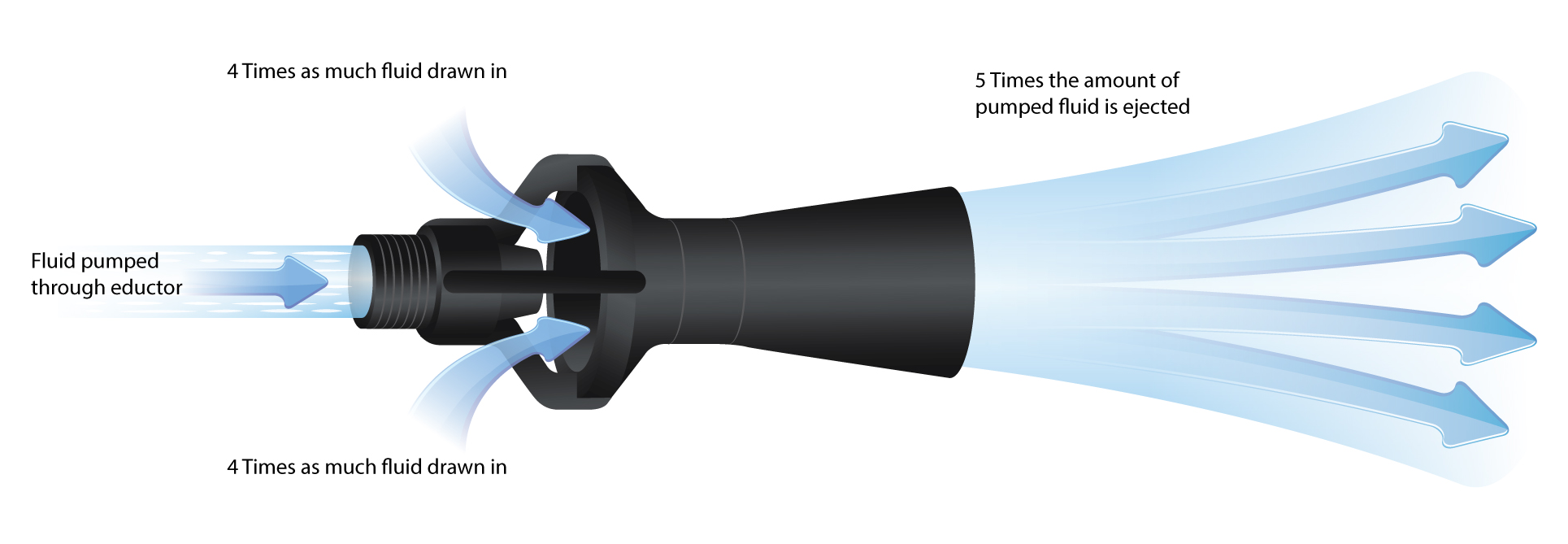

BETE Eductor mixing nozzles (BETE TurboMix ) operate submerged beneath the liquid level in the tank. They utilize a fundamental principle: increased velocity results in reduced pressure. These nozzles harness the fluid's velocity pumped into them, creating a low-pressure zone that draws surrounding liquid from the tank into the nozzle. Consequently, the pumped fluid efficiently blends with the tank contents, with the nozzle emitting three to five times the pumped fluid volume. This multiplier effect enhances mixing efficiency while utilizing a smaller pumping capacity.

The Role of BETE Mixing Nozzles in Tank Agitation

Even after combining liquids, mixing nozzles play a crucial role in agitating the combined fluid. For example, when the mixture contains solids lighter or heavier than the liquid, agitation prevents them from settling or floating. This is equally important for liquids with different densities or mixtures of oil and water-based compounds. Additionally, even uniform liquids can stagnate, promoting bacteria growth and temperature-based stratification. Agitation ensures even suspension of solids while discouraging bacterial growth through effective mixing.

One common setup is the pump-around system, where the pump's suction side is connected to the tank, drawing the liquid through the pipe. The discharge side of the pump is piped to the nozzle inlet. Liquid is drawn from the tank, pumped into the nozzle, and more liquid is entrained and emitted from the nozzle, propagating through the tank to keep the liquid in motion. Correctly positioned nozzles facilitate agitation and mixing without requiring moving components within the tank. Besides pump-around systems, other setups, such as supplying fresh feed to the nozzle inlet, are widely adopted. The fresh feed mixes with the tank's contents immediately and continues mixing as the exit jet propagates downstream.

Common Uses & Industries Benefiting from BETE Tank Mixing Nozzles

BETE Tank Mixing Nozzles find versatile applications across various industries:

- Aerobic & anaerobic digesters

- Preventing bacterial growth and thermal stratification

- Blending ethanol and bio-diesel

- Chemical Injection/Mixing

- Chemical Processing Industry

- Food & Beverage Processing Industry

- Homogenizing tank contents and facilitating chemical/biological reactions during pumping/draining

- Suspending particulates/solids or injecting steam/air

- Removing sludge and sediment from tank bottoms

Important Factors Influencing BETE Tank Mixing Nozzle Selection

When choosing a BETE Tank Mixing Nozzle, several critical factors should be taken into account:

- Applicable design specifications and mixing requirements

- Circulation, agitation/solids suspension, mixing/blending, solids sweeping, etc.

- Required material of construction for abrasive or corrosive environments

- Size & shape of tank/vessel

- Available nozzle mounting locations

- Available/required flow rates

- Available pressure drop (∆P) across the nozzle (∆P = supply pressure at nozzle inlet - process pressure outside nozzle)

/Petrochemical-processing-brochure.jpg)