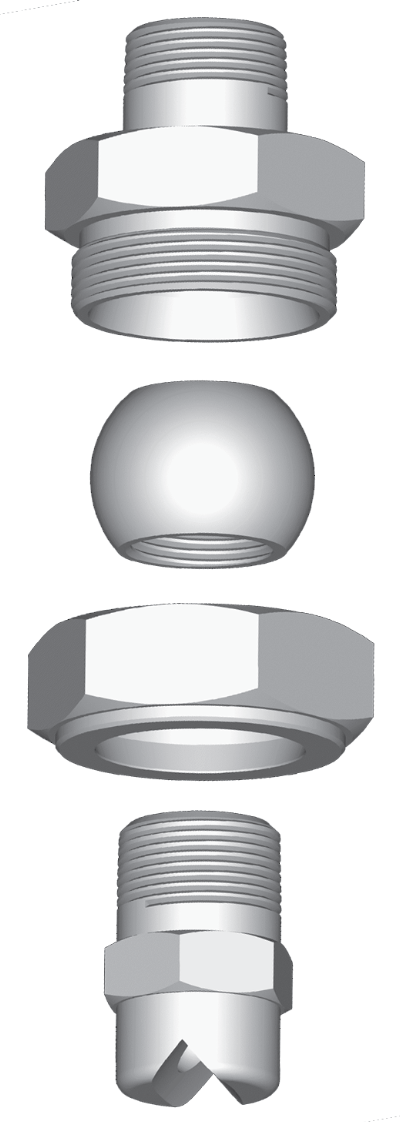

BETE Snap-In Nozzle Tips for Quick Set-Up and Change

Design Features of BETE SF Snap Release Nozzle Systems

- Nozzles can be quickly changed and aligned by hand without tools

- Clamp-on adaptor fits any style nozzle

- Quick set-up system features special “Snap-in” tips

- Polypropylene, resistant to most acids and alkalies

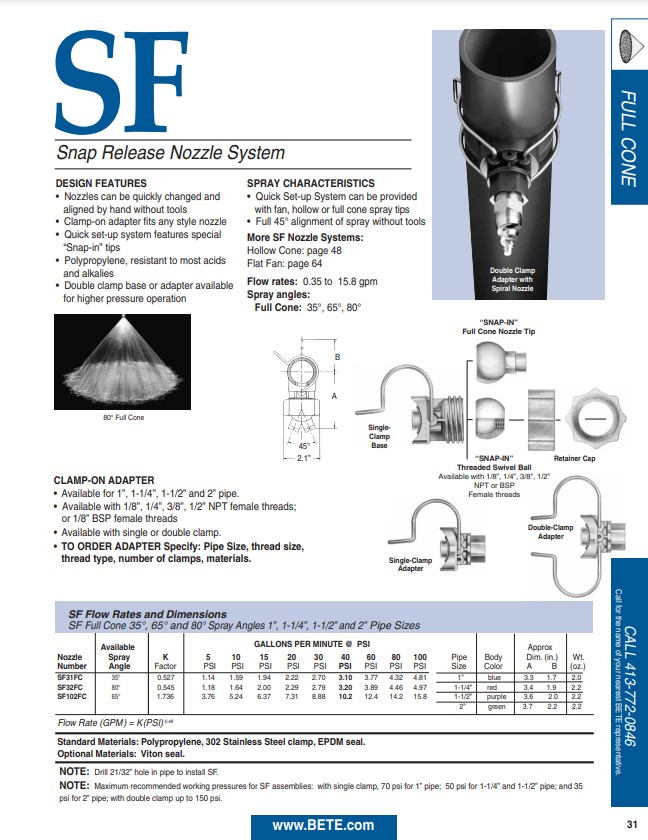

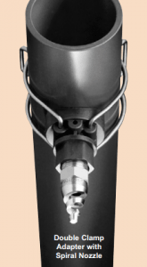

- Double clamp base or adapter available for higher pressure operation

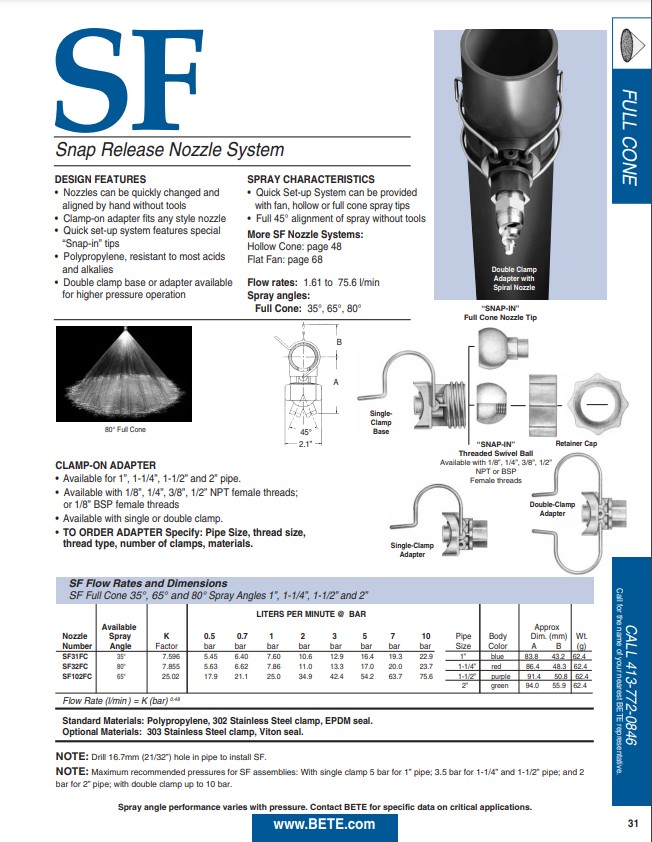

BETE SF Snap Release Nozzle Systems Spray Characteristics

- Quick set-up system can be provided with fan, hollow or full cone spray tips

- Full 45° alignment of spray without tools

- Flow rates: 0.35 to 15.8 gpm (1.61 to 75.6 L/min)

- Spray angles:

- Fan: 40°, 50°, 65°, 80°, 95°

- Hollow Cone: 50°, 65°, 90°

- Full Cone: 35°, 65°, 80°

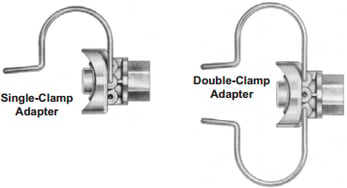

Clamp-On Adapters

- Available for 1”, 1-1/4”, 1-1/2” and 2” pipe

- Available with 1/8”, 1/4”, 3/8”, 1/2” NPT or BSP female threads (BSP threads available only in 1/8” size)

- Available with single or double clamp.

How Spray Pattern is Achieved for the BETE SF Snap Release Systems

- Fan – a thin flat sheet of liquid is produced when the fluid exits the orifice, and the spray begins to widen and gradually moves outward from the nozzle

- Full cone - atomization is achieved by the water being spun inside the nozzle and then exiting an orifice

- Hollow cone -the inlet of the nozzle and the direction of the spray are inline. Flow enters the nozzle and is directed by channels or vanes to swirl along the axis of the nozzle. The emitting spray is atomized in a hollow cone pattern