BETE Low Maintenance Interchangeable Fan Spray Nozzle Tips

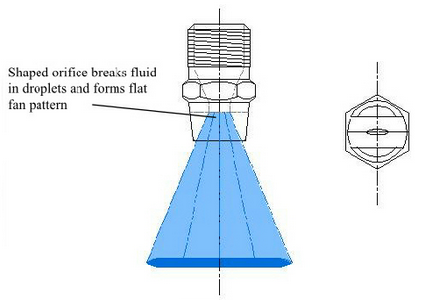

The flat fan pattern is effectively a line of spray. The impact of this spray is high when compared to full or hollow cone spray patterns but not as high as a solid stream nozzle. The droplet sizes produced by this type of nozzle are larger than cone nozzles, although very fine droplet flat fans can be created by some air atomizing flat fan nozzles. For a flat fan nozzle to cover an area, some relative motion is required. Commonly this motion is provided by a conveyor moving product under a series of flat fan sprays. Alternatively, the nozzle itself can be in action to provide complete coverage.

The BETE NFD spray nozzle is an elliptical orifice flat fan nozzle. With this standard nozzle design, the spray pattern is formed by the exit of the fluid through a shaped orifice. The slightly tapered nature of the flat spray pattern means that spray distribution is only partially even. The ends of the spray pattern have less fluid delivered. A series of nozzles with slightly overlapping spray patterns should be built to achieve a thoroughly even spray. Once the level of spray loss at the edges of the pattern is known, this is just a matter of simple trigonometry.

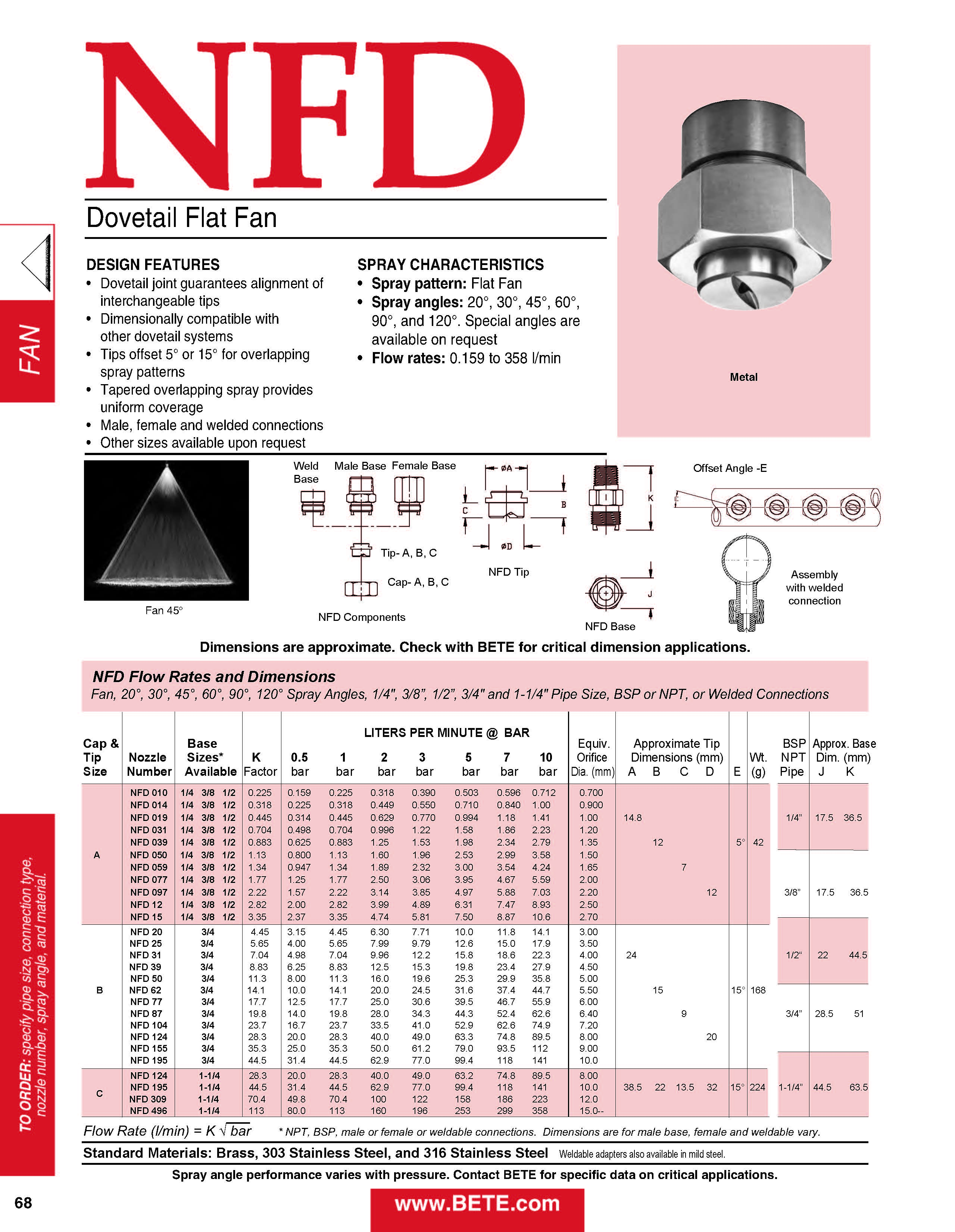

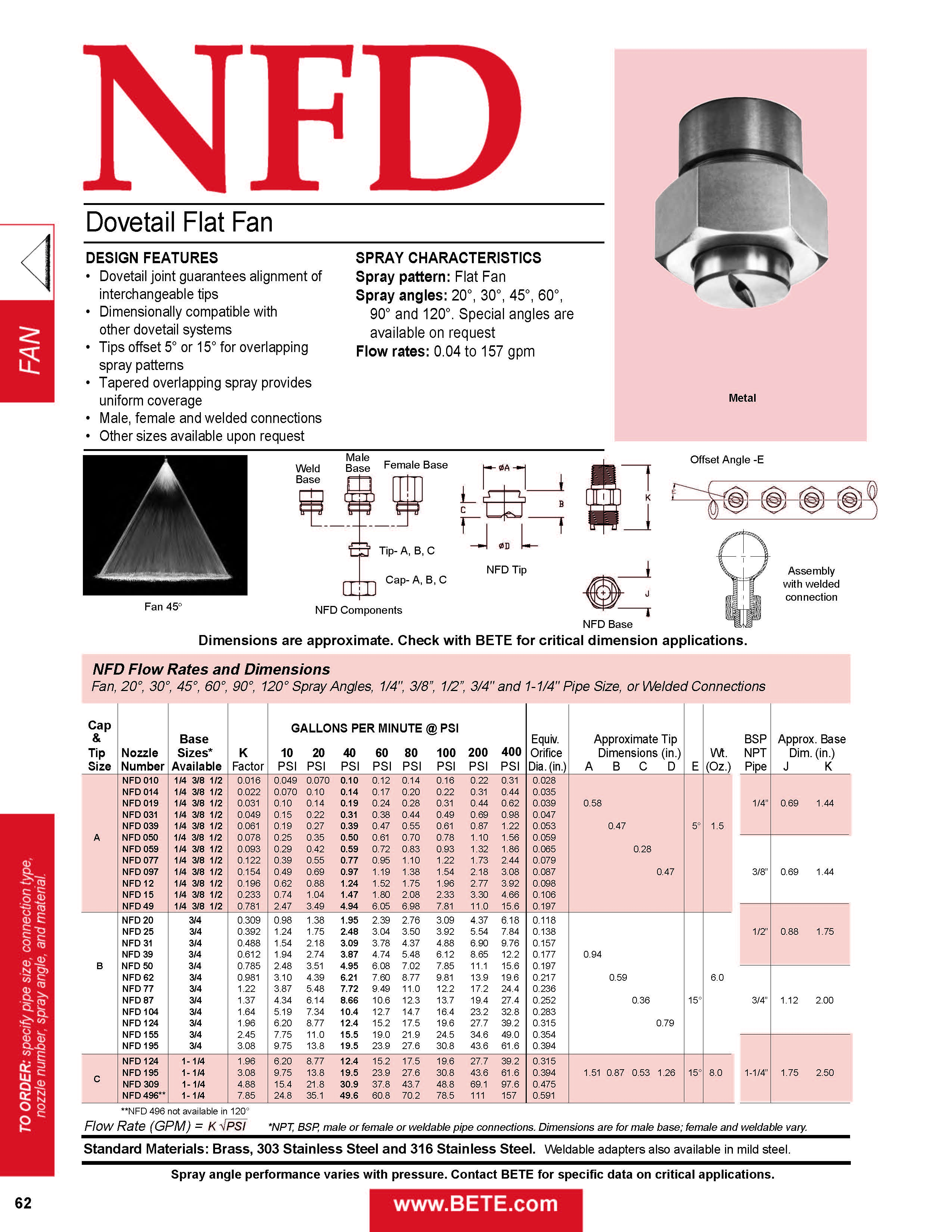

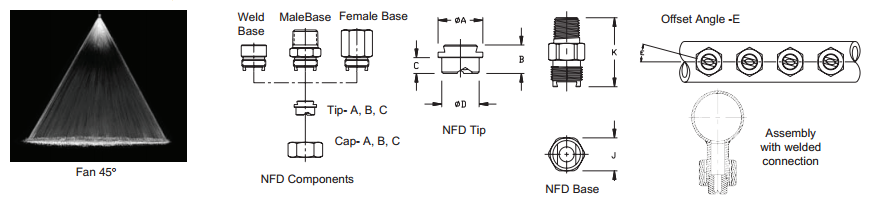

BETE NFD Spray Nozzles Design Features

- Dovetail joint guarantees alignment of interchangeable tips

- Dimensionally compatible with standard dovetail systems

- Tips offset 5° or 15° for overlapping spray patterns

- Tapered overlapping spray provides uniform coverage

- Male, female and welded connections

- Other sizes available upon request

Spray Characteristics of BETE NFD Spray Nozzles

Spray Pattern: Flat Fan

| Available Spray Angles | Flow Rate Range |

| 20 - 120° | 0.0358 to 176 gpm |

| Available Connection Types | Materials |

|

Brass, 303, 316 |

How Spray Pattern is Achieved

- Tips offset 5° or 15° for overlapping spray patterns

- The tapered overlapping spray provides uniform coverage

- Relatively coarse atomization