Reduce Down-Time With Patented Stationary Tank Cleaning Devices

BETE HydroClaw Clog Resistant Stationary Tank Cleaning Spray Nozzle for Quick, Efficient Tank Cleaning

The unique, patent-pending, clog-resistant design quickly cleans tanks and eliminates maintenance downtime associated with clogged spray balls. Ideal for tanks up to 10 ft. (3 m) in diameter often found in the food, beverage, chemical, and personal care industries where superior cleaning with reduced cycle times and low water, energy, and chemical consumption are important considerations.

Spray Pattern:

What causes spray balls to clog?

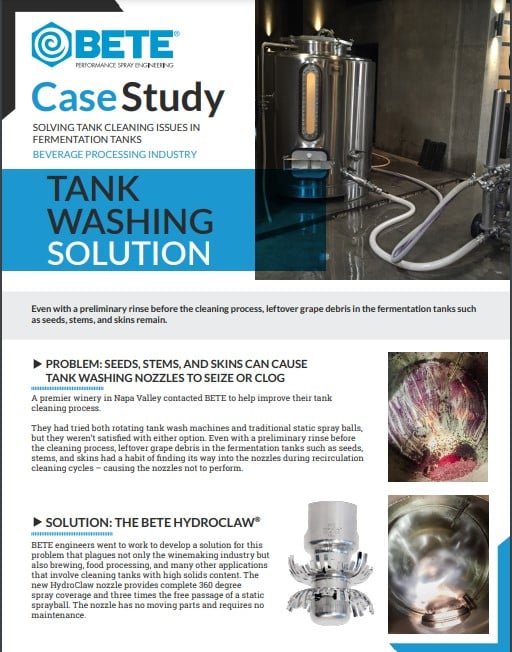

- Wineries: stems, skins, and seeds

- Breweries: grains, obstinate hops, and fruits

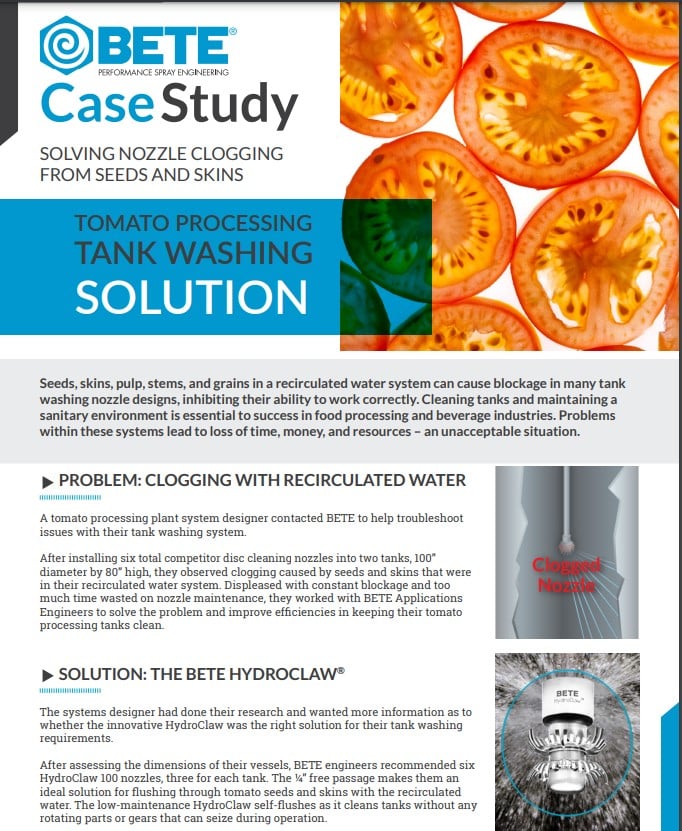

- Food and Beverage Producers: skins, fruit pulp, and residue build-up

- Juice Processing Plants: fruit seeds and pulp

- Sugar Processing Plants: sticky sugar residue

- Tomato Processing Plants: seeds and skins

Design Features of the BETE HydroClaw Tank Washing Nozzles

- Unique, patent-pending, clog-resistant design with no moving parts

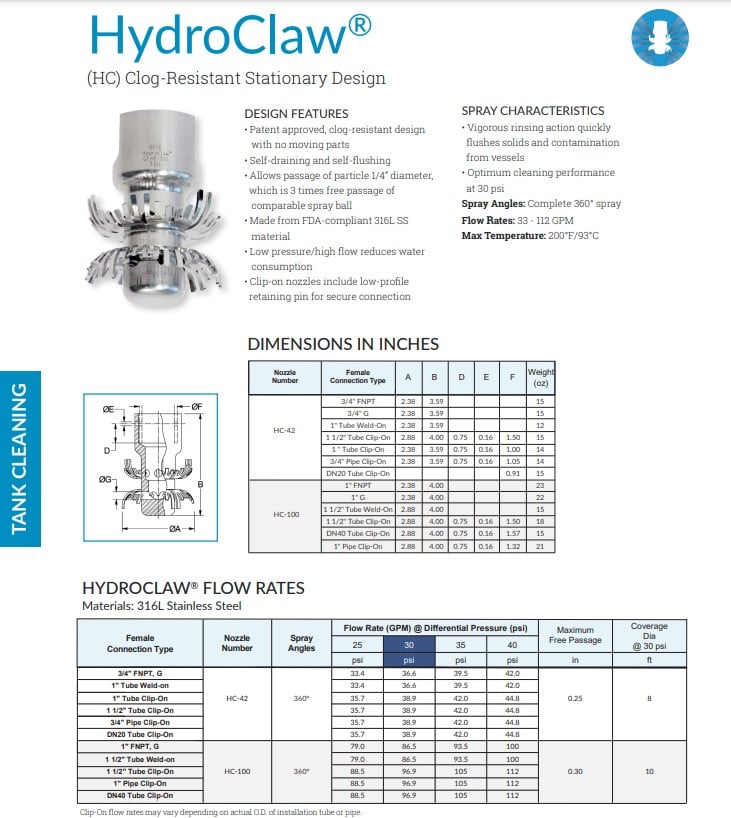

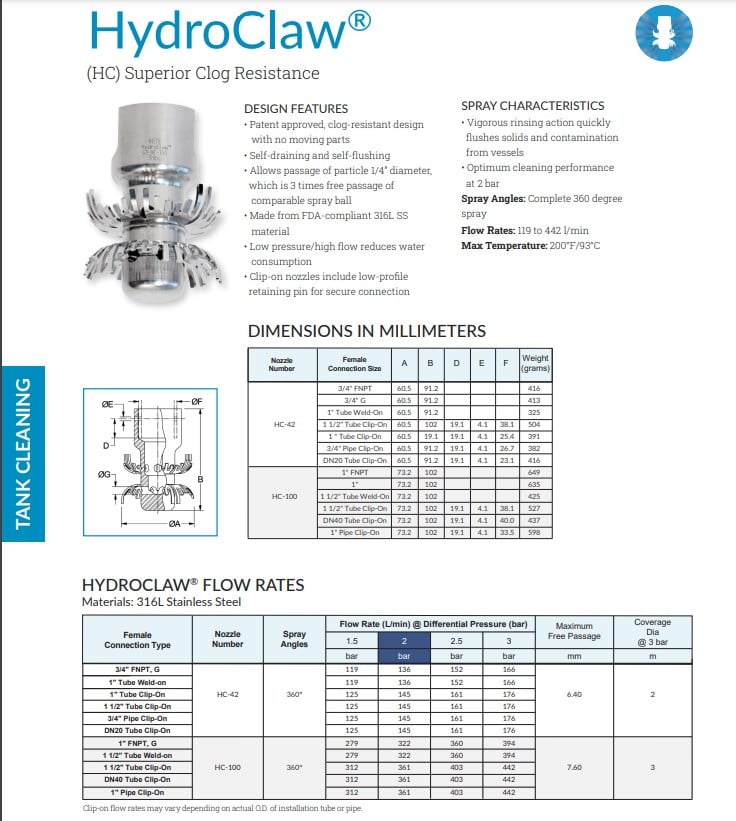

- HC-42 allows passage of particles 1/4” (6.4 mm) in diameter, HC-100 allows passage of particles over 1/4” (7.6 mm) in diameter – three times the free passage of a comparable spray ball

- Made from FDA compliant 316L stainless steel for use in food-grade and sanitary Clean-In-Place (CIP) applications

- Low pressure/high flow operation quickly cleans tank walls to reduce overall water consumption compared to a static spray ball

- Self-draining and self-flushing

- Laser-welded for durability

- Designed for industrial or hygienic small to medium sized tanks

- Available in a variety of connection sizes and types, including threaded, clip-on and welded

- Clip-on nozzles include low-profile retaining pin for secure connection

- Fits through compact openings: either 2-1/2″ (63.5 mm) or 3″ (76 mm) diameter

- Optimal cleaning performance achieved at 30 psi (2 bar)

Spray Characteristics of BETE HydroClaw Tank Washing Nozzles

- Vigorous rinsing action quickly flushes solids and contamination from vessels

- Complete 360° omnidirectional coverage

| Available Spray Angle | Flow Rate Range |

| 360° | 30 to 100 gpm |

| Available Connection Types | Material |

|

316L |

How Spray Pattern is Achieved

- A limited number of large diameter orifices create heavy straight jets that disperse using specially designed deflection cups. These deflection cups are designed with a slot to help break the jets into a uniform 360° omnidirectional spray pattern.