State-Of-The-Art Plastic AODD Pumps

________________________________________________________________________________________________________________________

The development of the Almatec® E-Series was based on the extensive experiences with the proven pump models. The solid design with distinctive wall thicknesses, the flange connection capability, the ring tightening structure and more construction features are responsible to meet the customer demands of safety, quality and reliability. Six pump sizes available with optional equipment's cover most applications in the market. Pulsation dampeners are available as screw-on and flanged models.

Features at a Glance:

- Air-operated diaphragm pumps in solid design

- Housing made of PE or PTFE, both also available in a conductive version

- Interchangeability to the previous A-Series

- Six sizes from DN 8 to DN 50

- Max. capacities of 0.9 to 35 m³/h

- Increased pump safety due to innovative ring-tightening structure

- Compared to the previous A-Series, increased capacity and decreased air consumption thanks to an optimized flow pattern, decreased noise level

- Models available with ATEX, EC1935/2004, FDA, USP Class VI approval

- Exterior free of metal

- Optimized diaphragm fixin

- Different possible port configurations

- Ball or cylinder check valves with identical interior design

- Maintenance and lubrication-free air control system PERSWING P® without dead center

- Composite diaphragms with integrated metal core, no diaphragm discs

- Proof against dry running and overloading, self-priming, insensitive to solids

- Gentle displacement

- Can be infinitely controlled via the air volume

- No drives, no rotating parts, no shaft seal

- Unattended operation with long service life

- Easy to start up

- Integrated muffler

- Recessed tie rods

- Low noise levels

- Screw-on or flanged pulsation damper

- Draining system

- Barrier chamber system

- Diaphragm monitoring

- Stroke counter

- Flange connection

- Transport cart

Materials:

| PART | MATERIALS |

|---|---|

| Housing | PE, PTFE, PE Conductive (ATEX), PTFE Conductive (ATEX) |

| Diaphragms | EPDM, PTFE/EPDM, PTFE modified/EPDM, NBR, ATEX variations |

| Ball Valves | EPDM, PTFE, NBR, Stainless Steel |

| Cylinder Valves | PTFE |

Technical Data:

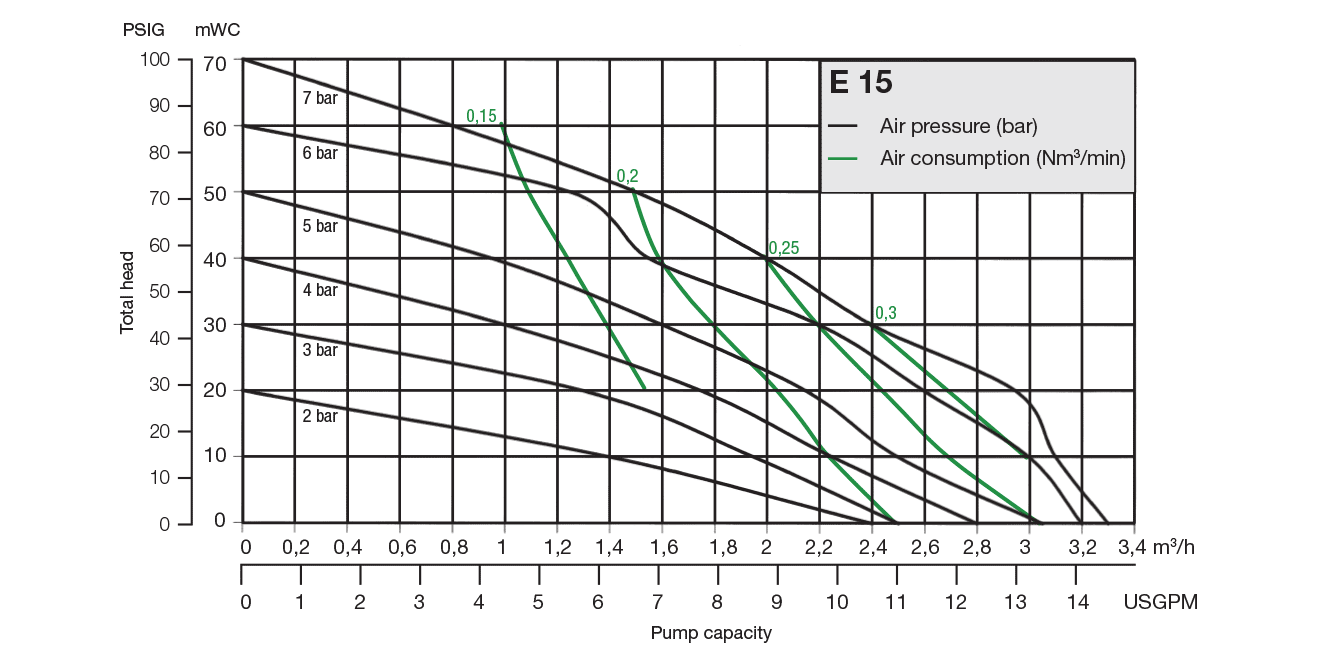

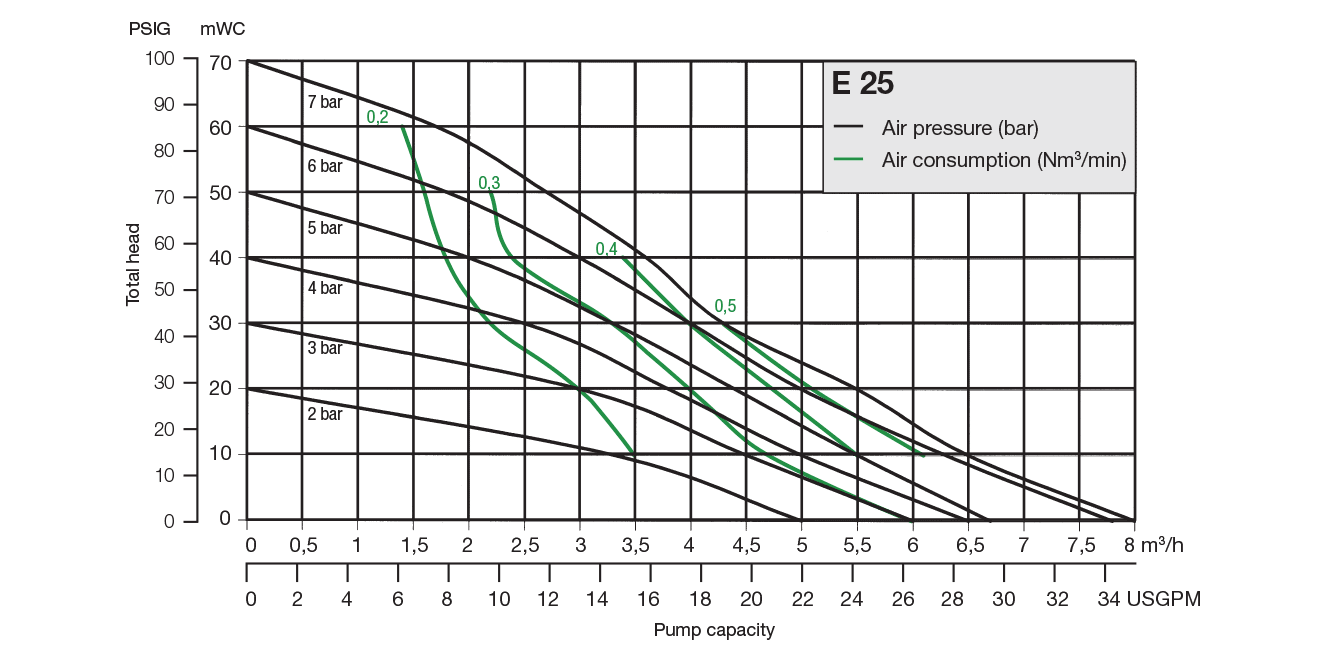

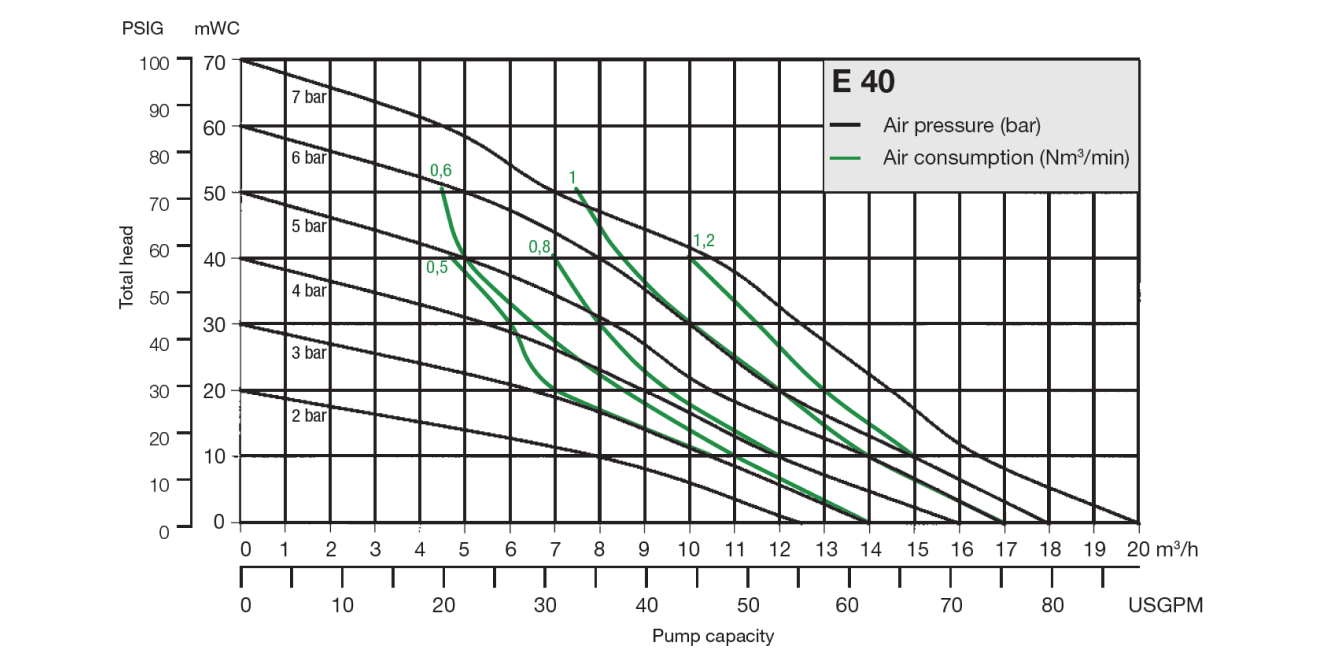

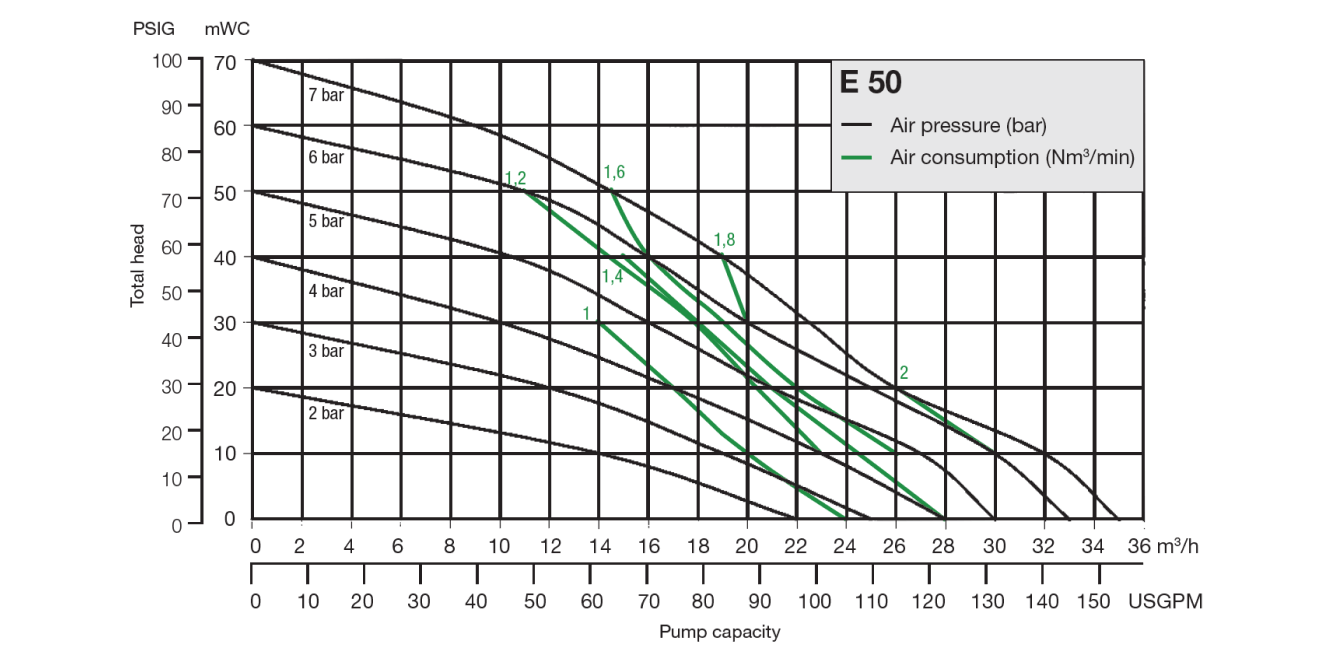

| PUMP SIZE | E 08 | E 10 | E 15 | E 25 | E 40 | E 50 | |

|---|---|---|---|---|---|---|---|

| Dimensions, mm (in.) | Length | 88 (3.5) | 110 (4.3) | 166 (6.5) | 220 (8.7) | 304 (12.0) | 399 (15.7) |

| Width | 128 (5.0) | 147 (5.8) | 189 (7.4) | 255 (10.0) | 353 (13.9) | 430 (16.9) | |

| Height | 129 (5.1) | 169 (6.7) | 240 (9.4) | 320 (12.6) | 432 (17.0) | 552 (21.7) | |

| Nominal port size | NPT | 1/4" | 3/8" | 1/2" | 1" | 1 1/2" | 2" |

| Air connection | BSP | R 1/8 | R 1/8 | R 1/4 | R 1/4 | R 1/2 | R 1/2 |

| Weight, kg (lb) | PE | - | - | 7 (15) | 15 (33) | 34 (75) | 66 (146) |

| PTFE | 2 (4) | 5 (11) | 12 (26) | 29 (64) | 69 (152) | 131 (289) | |

| Max. particle size of solids for pumps with ball valves | mm (in.) | 2 (0.08) | 3 (0.12) | 4 (0.16) | 6 (0.24) | 9 (0.35) | 11 (0.43) |

| Suction Lift Dry, mWC (ft) | Cylinder Valves | 1 (3.3) | 2 (6.6) | 3 (9.8) | 4 (13.1) | 5 (16.4) | 5 (16.4) |

| Suction Lift Dry, mWC (ft) | Ball Valves | 0,5 (1.6) | 1 (3.3) | 2 (6.6) | 3 (9.8) | 4 (13.1) | 4 (13.1) |

| Suction Lift Wet, mWC (ft) | 9 (29.5) | 9 (29.5) | 9,5 (31.2) | 9,5 (31.2) | 9,5 (31.2) | 9,5 (31.2) | |

| Max. driving and operating pressure | bar (psig) | 7 (100) | 7 (100) | 7 (100) | 7 (100) | 7 (100) | 7 (100) |

| Max. operating temperature, °C (F) | PE | - | - | 70 (158) | 70 (158) | 70 (158) | 70 (158) |

| PTFE | 100 (212) | 100 (212) | 120 (248) | 120 (248) | 120 (248) | 120 (248) | |

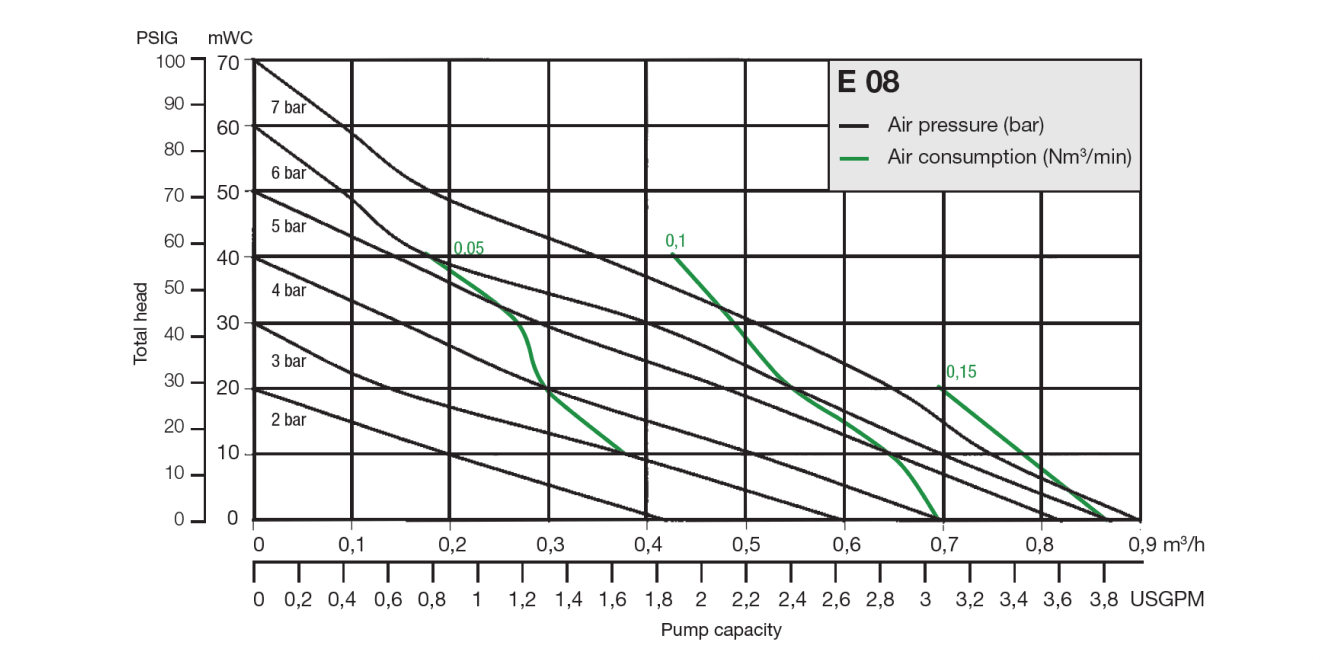

| Max Capacities | 0.9 m³/h 15 l/min 4 gpm |

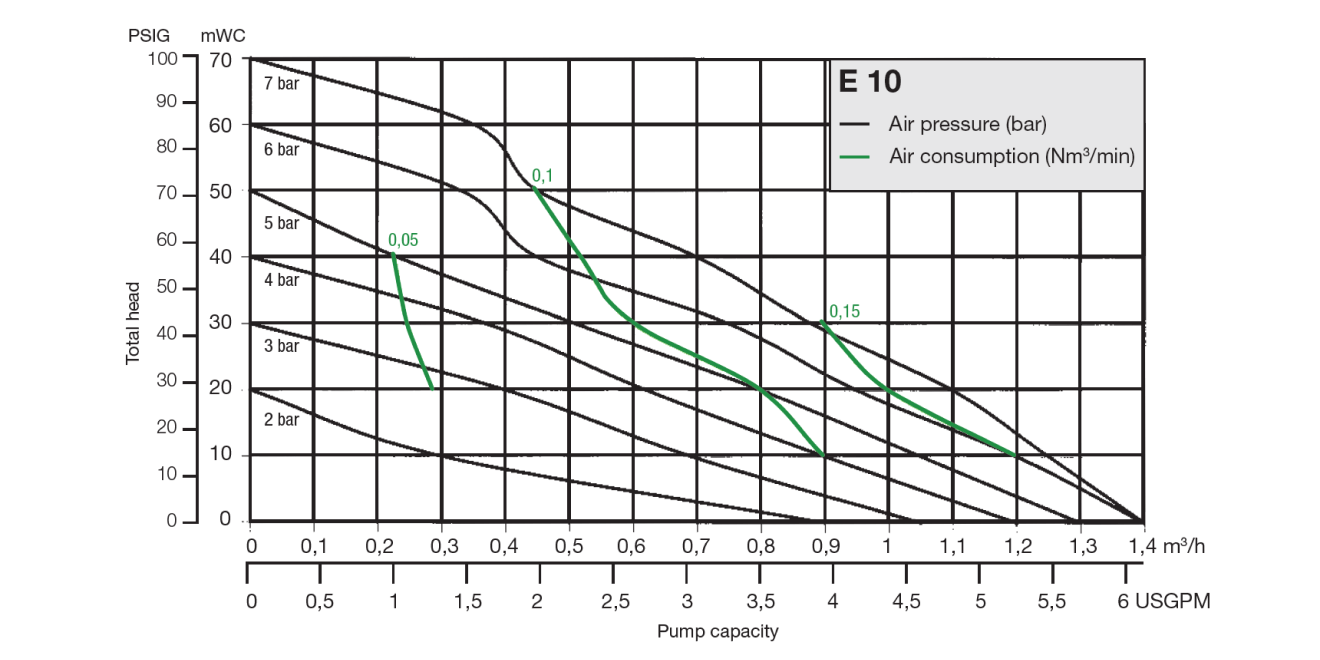

1.4 m³/h 23 l/min 6 gpm |

3.4 m³/h 55 l/min 15 gpm |

8 m³/h 130 l/min 35 gpm |

20 m³/h 330 l/min 88 gpm |

36 m³/h 600 l/min 160 gpm |

These technical data apply to Almatec E-Series standard pumps without optional equipment and dampers.

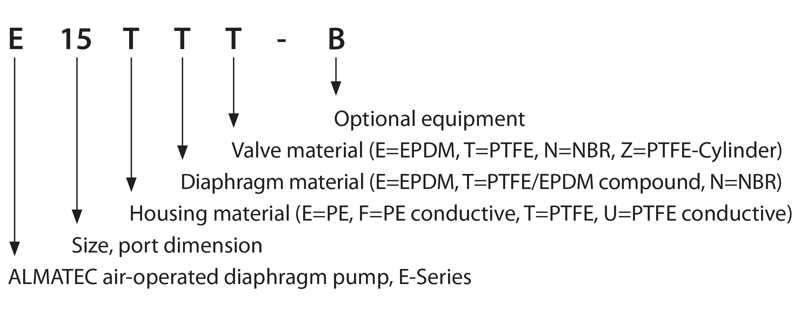

Code System:

Performance:

|

|

|

|

|

|