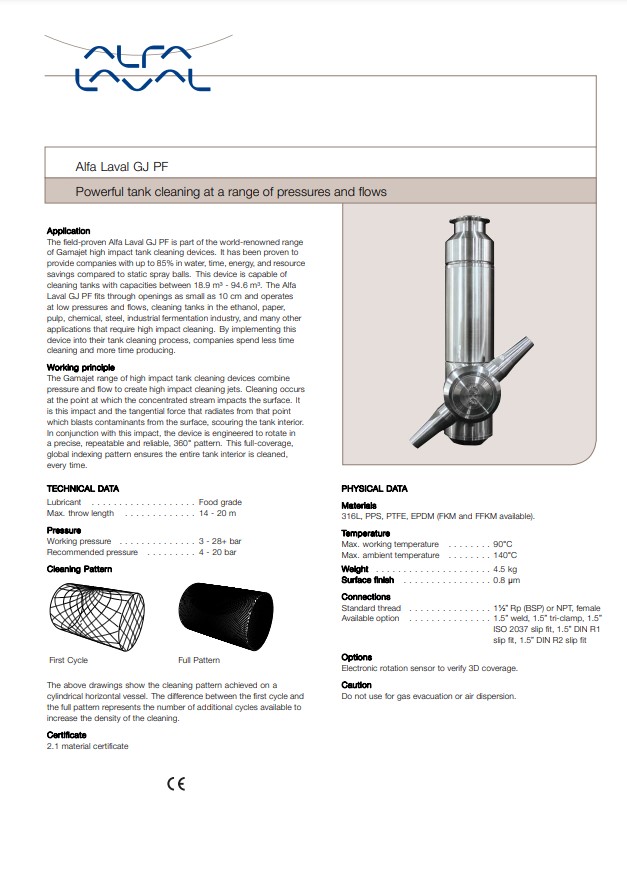

Powerful, Sanitary Tank Cleaning for a Variety of Pressures and Flows — Self-Cleaning | Self-Flushing | Self-Lubricating

The Alfa Laval Gamajet GJ PF FT tank cleaning machine was specifically engineered to offer the most efficient and effective cleaning for vessels with capacities of 5,000 to 25,000 gallons. The durable machine offers optimal cleaning at a variety of pressures and flows.

The sanitary design of the GJ PF FT makes it ideal for use in food and beverage, pharmaceutical and personal care industries, for both portable and permanent applications. The standard machine is self-cleaning, self-flushing, and self-lubricating, requiring no oil or grease in the gear train. All components of the GJ PF FT are made from FDA compliant materials.

The key to the GJ PF FT’s versatility and durability is the use of an oversized gear head that efficiently generates the proper torque to rotate the unit. The larger components last 20-30% longer than traditional drive mechanisms, making the GJ PF FT our most durable design to date. The large gear reduction allows the GJ PF FT to operate at lower pressures and higher flows when compared to other tank cleaning machines. Like other Alfa Laval tank cleaning machines, the GJ PF FT uses the same proven l impingement cleaning pattern, scouring 100% of the tank, every time.

Benefits:

- Sanitary Design

- Operates at Lower Pressures

- Powerful: 25 lbs (11.5 kg) of cleaning force at 25′ (7.5 m)

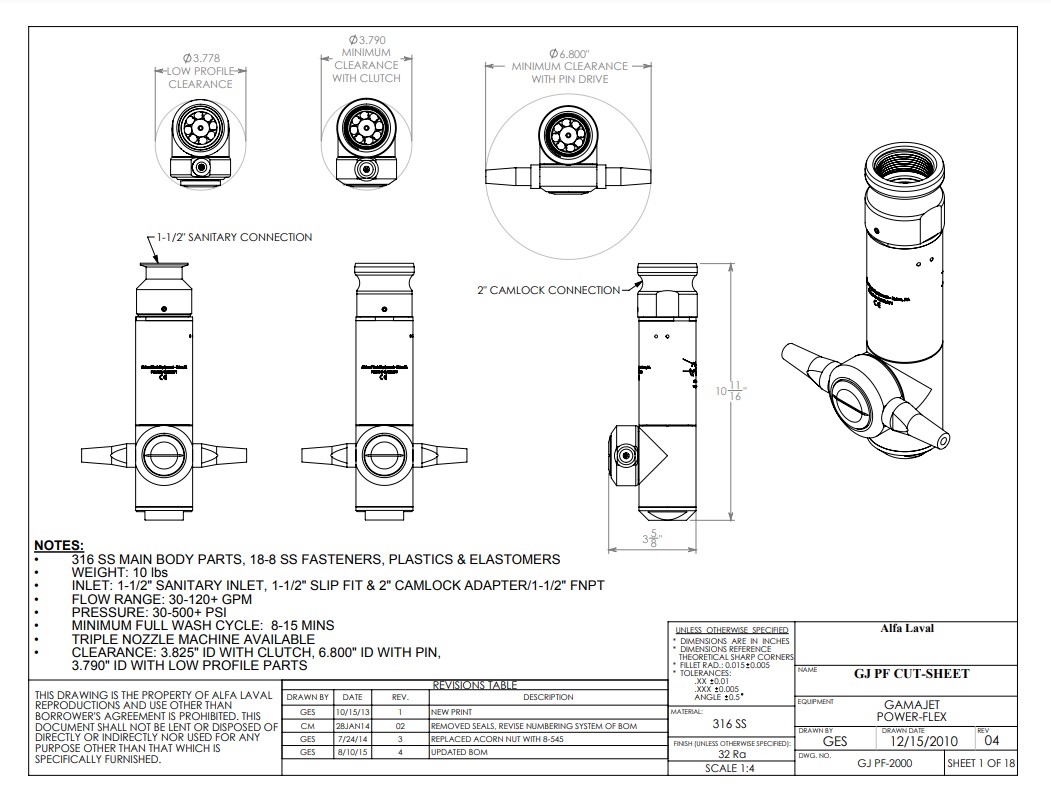

Overall Dimensions:

- Height: 10.75 in. (273 mm) Custom lengths available

- Body Diameter: 3.87 in. (98 mm)

- Weight: 10 lb (4.5 kg)

Clearance:

- Pin Drive:

Dual or quad: 6.88 in. (175 mm) - Clutch Drive:

Dual or low profile: 3.8 in. (98 mm)

Operating Range:

- Pressure: 40 to 400 psi (3 to 28 bar)

- Temperature: 0° to 200°F (0° to 93°C)

- Flow Rate: 20 to 70 gpm (75.7 to 264 l/min)

- Cleaning Radius: 30 ft. (9 m)

- Wash Cycle Time: 8-20 min.

- Impact: 25 lbs (11.5 kg) at 25 ft. (7.5 m)

Specifications:

| Inlet Connection: | 1.5 in. Tri-Clover, 1.5 in. slip-fit (R-clip), 1.5 in. NPT-Female, 2 in. Camlock Plug |

|---|---|

| Construction/Design: | Parts are machined from 316-L Stainless Steel investment castings or bar stock. |

| Impeller & Final Shaft: | For increased wear resistance, the input and output shafts are plasma-sprayed with a Chromium Oxide coating on Stainless Steel. |

| Shaft & Gearbox Bushings: | Turbine shaft thrust is absorbed by a Tungsten carbide bushing. Gear bushings are food grade polyphenylene sulfide. |

| Elastomers: | O-Ring materials are selected for each application. EPDM is standard, with Viton and Kalrez available. Other materials can be supplied on special order. |

| Nozzles: | Nozzle sizes from 1/4 in. (6.35 mm), 5/16 in. (7.94 mm) to 3/8 in. (9.53 mm) |

| Drive Mechanism: | The wash fluid enters the GJ PF at the inlet collar where it encounters and spins turbine blades. The turbine blades are attached to the top of the drive or rotor shaft. The bottom of this shaft is connected to the inside of a flow-thru, robust planetary gearhead which then turns the body in the horizontal plane and the nozzles in the vertical plane. |

| Planetary Gearhead: | The flow-thru planetary gearhead uses the wash fluid as a lubricant. All internal gearhead parts are stainless steel. |

| Operation & Maintenance: | Complete operating and maintenance procedures are covered in a detailed instruction manual furnished with all machines. Ready availability of spare parts or kits, and ease of on-site maintenance minimizes the need for repairs. Prompt factory overhaul or repair service is always available. Replacement parts are stocked year round. Special 24-48 hour delivery available upon request at no extra charge. |