Affordable Tank and Tote Cleaning

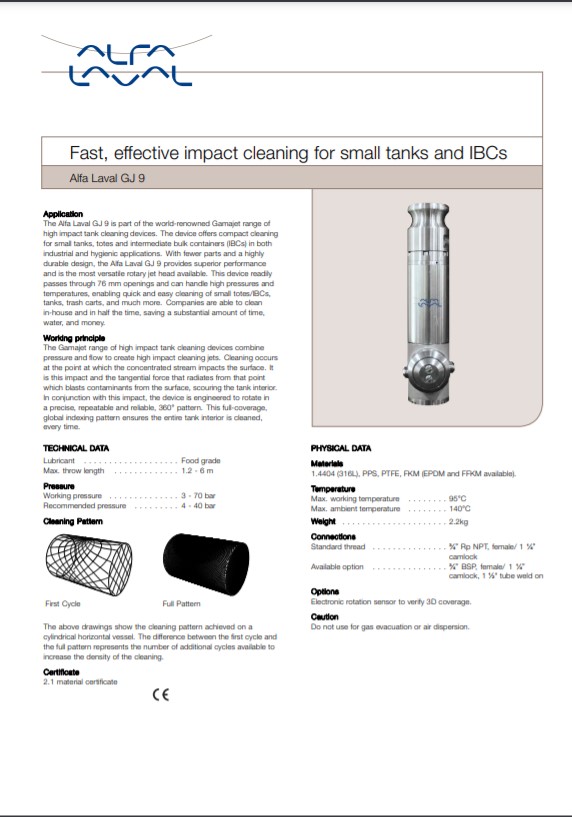

Alfa Laval Gamajet GJ9 tank cleaning device offers compact cleaning for small and mid-sized tanks with fewer parts, and a highly durable design, providing superior performance at an affordable price, making it the ultimate tote washer. Fewer parts means fewer breakdowns and lower maintenance costs. Coupled with our renowned product quality, the revolutionary GJ 9 tank cleaning device durability allows its use in rugged applications in the harshest environments.

The GJ 9 is another high-quality tank cleaning device from Alfa Laval. Originally designed for tote cleaning applications, the GJ 9 tank cleaning device is also perfect for other small and mid-sized tank cleaning applications. Its 360° spray pattern provides thorough scouring of the entire tank or tote, reducing operating time and costs. At an unbelievably low price, the GJ 9 tank cleaning device sets the standard for cost-effective impingement tank cleaning and tote washing.

Benefits:

- Cleans Totes and Other Vessels in Under 4-12 minutes

- Powerful: 12 lbs (5.5 kg) of Cleaning Force at 10’ (3 m)

- Compact, Durable and Easy to Maintain

Operating Range:

- Pressure: 40 to 1000+ psi (3 to 70 bar)

- Temperature: 32° to 250°F (0° to 121°C)

- Flow Rate: 4 to 30+ gpm (15 to 113 l/min)

- Cleaning Radius: 7.5 ft. (2.5 ms)

- Wash Cycle Time: 12 min.

- Impact: 12 lbs (5.5 kg) at 10 in. (3 m)

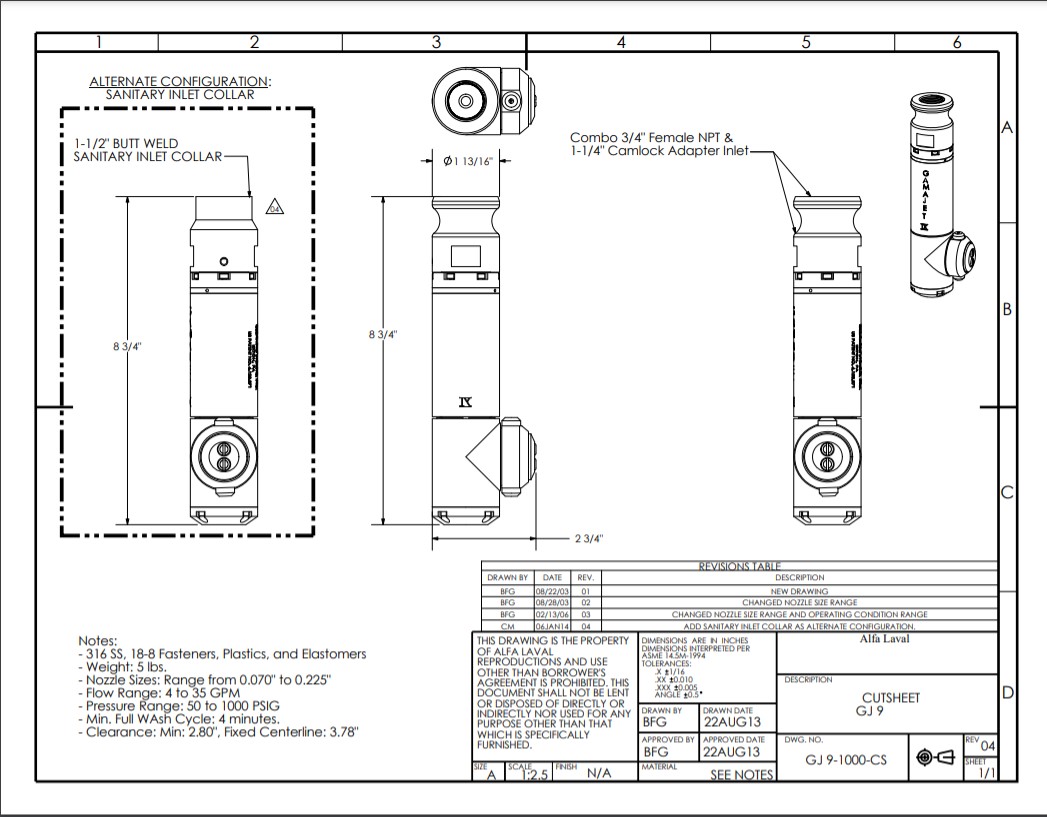

Overall Dimensions:

- Height: 8.8 in. (225 mm)

- Body Diameter: 1.80 in. (46 mm)

- Weight: 5 lb (2.4 kg)

- Clearance: 2.76 in. (70 mm) minimum passageway I.D.

Other Options:

- Quad Nozzles for Faster Cleaning

Accessories:

|

Alfa Laval Gamajet GJ ToteBlast StationClean any Tote or Bulk Container in 3 to 7 Minutes The... |

Alfa Laval Gamajet TriPod AttachmentFor Temporarily Mounting an Alfa Laval GJ 4, GJ8, GJ9 and GJ... |

Specifications:

| Inlet Connection: | 3/4 in. NPT with 1 1/4 in. Camlock, ¾ in. BSP with 1 ¼ in. Camlock Tri-clover sanitary inlets are available. |

|---|---|

| Construction/Design: | Parts are machined from 316-L Stainless Steel investment castings or bar stock. |

| Impeller & Final Shaft: | For increased wear resistance, the rotor shaft is plasma-sprayed with a Chromium Oxide coating on stainless steel. |

| Shaft & Gearbox Bushings: | Rotor shaft thrust is absorbed by a tungsten carbide bushing. Gearbox bushings are carbon-filled-reinforced polyphenylene sulfide. |

| Bearings: | Bearings in the rotating tee and nozzle housings are self-lubricating, carbon-fiber-reinforced polyphenylene sulfide. |

| Bearing Cups: | Main body castings are protected by replaceable 316-L Stainless Steel cups for extended frictional wear life. |

| Static Seals: | O-ring materials are selected for each application. Viton® is standard, with Kalrez® and EPDM available. Other materials can be supplied on special order. |

| Dynamic Seals: | Dynamic shaft seals are spring-loaded, double-lipped and made of PTFE. They are reinforced with carbon fiber for extra-long wear and protection against leakage, abrasion and deposit build-up. |

| Nozzles: | Dual or quad 0.05 in. (1.4 mm) to 0.225 in. (5.7 mm) orifice diameters. Other nozzle sizes available upon request. |

| Drive Mechanism: | The wash fluid enters the Alfa Laval Gamajet at the inlet collar where it encounters and spins rotor blades. The rotor blades are attached to the top of the rotor shaft. The bottom of this shaft is connected to the inside of a sealed, planetary gearhead which then turns the body in the horizontal plane and the nozzles in the vertical plane. |

| Planetary Gearhead: | The sealed planetary gearhead has an external casing made of steel, surface-anodized to increase corrosion resistance. This sealed gearhead is located inside the gearbox, which itself is sealed, the output shaft are stainless steel. |

| Lubricant: | A food grade lubricant is inside the sealed gearhead casing. No customer-supplied or user-maintained lubricant is needed. |