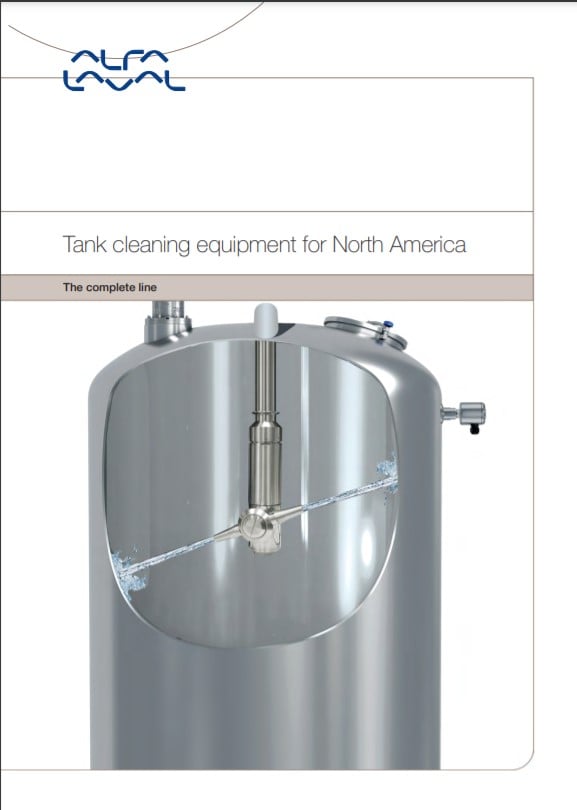

Automated Tank Cleaning for Food & Beverage Applications Feature Self-Cleaning Designs, Sanitary Inlet Adaptors and made of FDA Approved Materials

Whether you’re cleaning 80 foot process vessels with complex mixing systems, kettles, blenders, or totes, you need to ensure the job is done thoroughly – every time. The importance of avoiding contamination, meeting regulatory standards, reaching sustainability goals, and ensuring product quality is paramount.

Many plants operate on a 24-7-365 schedule, at maximum production. Under such pressure, efficiency and effectiveness are a must. We understand this pressure, and have developed the best solution for automated tank cleaning in the food and beverage industry.

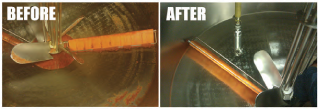

Food Processing Tank with Center Agitator

Benefits:

- Full Coverage Cleaning

- Meet Regulatory Standards

- Reduce Wash Fluid Usage

- Decrease Cleaning Time

- Eliminate Cross-Contamination

- Eliminate Confined Space Entry for Manual Cleaning

Residues:

- Tomato Paste; Sauce; Mustard; Molasses/Sugars; Soup; Fruit Juice; Yogurt; Milk; Cheese; Meat

Applications:

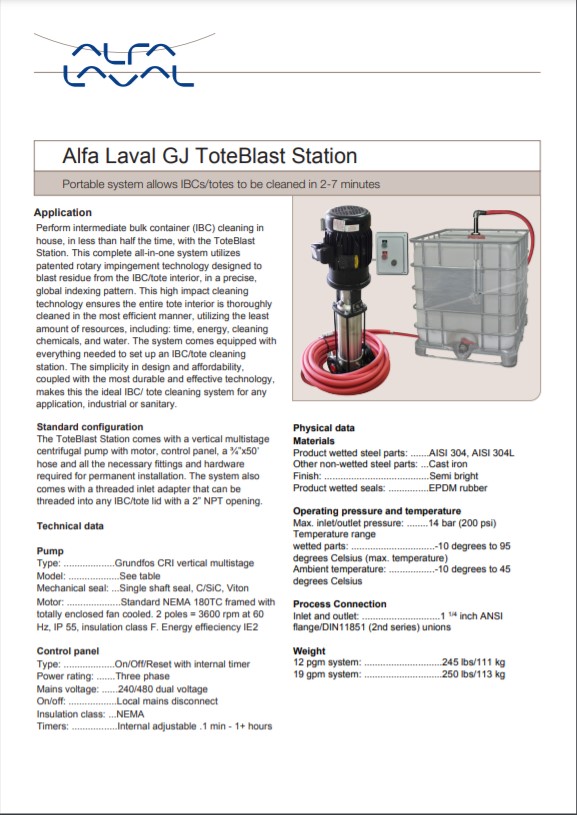

- Storage Tanks; Process Tanks; Blenders; Evaporators; Kettles; Mixers; Drums; Dryers; Totes/Bulk Containers/IBCs

360 degree Tank Cleaning for Food Processing Applications. Quick, Effective, Powerful.

Related Products – Alfa Laval Tank Cleaning Devices