The Single Filter Multi-Basket is specially designed to be compact and easily maintained, with basket removal easier compared to other units with similar pipe size connections.

Principle of Operation

Airpel Series OV multi basket filters are designed for the removal of solids from liquid flows. Any solids larger than the selected filtration media are retained within the filter baskets (in to out filtration) and can then be disposed of safely and in a controlled manner. The OV series is used in liquid handling installations where the flow can be interrupted for short  periods to allow the removal of the basket for cleaning.

periods to allow the removal of the basket for cleaning.

Construction

All Airpel Series basket filters are of cast construction and house high quality stainless steel cylindrical baskets. The design allows quick and easy access to the baskets so they can be cleaned and re-used, helping reduce operating costs and controlling debris levels. Specially designed to be compact and easily maintained the multi basket range is of cast construction and is supplied with four or five high quality stainless steel cylindrical baskets.

Airpel Series Features and Benefits – OV Multibasket (Single / Simplex)

| Feature | Advantage | Benefit |

|---|---|---|

| Robust simple design | Low cost effective unit | Keeps within budget constraints |

| Easy access cover design | Quick opening for access to basket(s) | Reduced down time and no tooling required |

| Compact Design | Smaller foot print | Can be installed in tight / small locations |

| Multi basket option | High levels of filtration area and more compact design (Compared to ‘like for like’ products) | Less space required for installation and high filtration area gained |

| Standard Airpel Design | Wide range of sizes and materials available from standard stock | Meets customers delivery and budget requirements |

| Basket design | Debris is held within basket | Re-use, easier & cleaner to dispose of unwanted filtered solids |

| Higher filtration area / volume than ‘Y’ types or conical filters | Lower clean pressure differential and greater dirt holding capacity | Less down time, potential smaller filter selection |

The Single Filter Multi-basket is specially designed to be compact and easily maintained, with basket removal easier compared to other units with similar pipe size connections.

The filter is of cast construction and is supplied with four or five high quality stainless steel cylindrical baskets depending upon the size. Ideal for use in liquid handling installations where the flow can be interrupted to allow for the removal of baskets for cleaning.

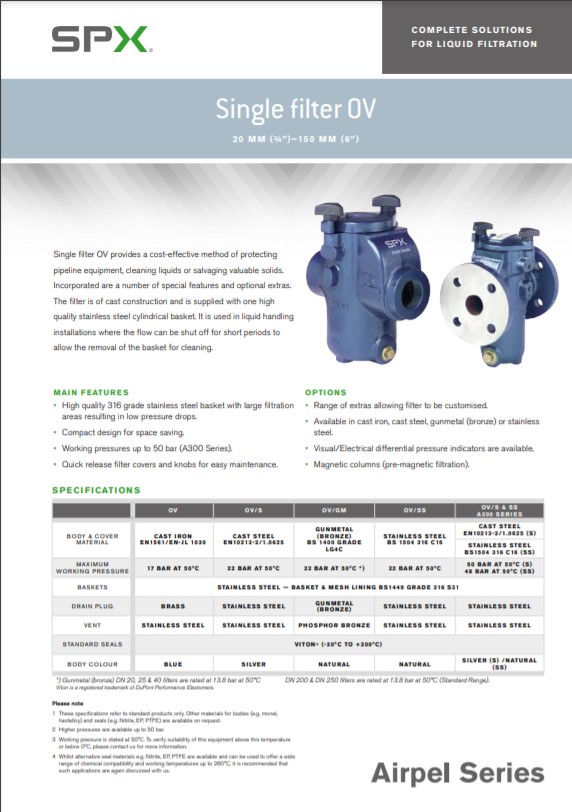

Specifications

- 200mm (8”) & 250mm (10”)

- Flanged and Screwed connection options

- Materials in Cast Iron, Cast Steel, Stainless Steel and Gunmetal

- Drain plug

- Quick release cover design for easy access

- Filtration levels down to 10 micron

Options

- Heating Jackets

- Air vents

- Differential Pressure Indicators (DPI)

- High temperature / pressure options

- Exotic basket materials available

- Magnetic basket inserts

- DIN sensors to provide remote high DP signal

Protect Pipeline Equipment Against Damage

Machinery such as pumps and valves can be broken by grit, metal fragments, etc. while nozzles and heat exchangers have narrow construction that could easily become blocked, this equipment is expensive to repair / replace and the cost of downtime could be crippling, so the installation of a strainer ensures that the primary equipment is protected from any unplanned outage.

Typical Applications would include:

- Nozzle protection

- Heat exchanger protection

- Valve protection

- Pump protection

Remove particles from fluid product

Even if pipeline equipment is not at risk particles in discharge may breach environmental legislation or product acceptance criteria, so the use of a strainer / filter can prove to be a cost effecting and efficient way to maintain the process fluids quality whilst maintaining working standards.

Common industries where product quality is essential:

- Water treatment

- Food and beverage

- Pharmaceutical

- Paints, inks and varnishes, etc.