Open Top Headbox Shower Eliminates Pulp Build-Up

Open Top Headbox Shower Eliminates Pulp Build- up in a Paper Production Factory

THE CHALLENGE

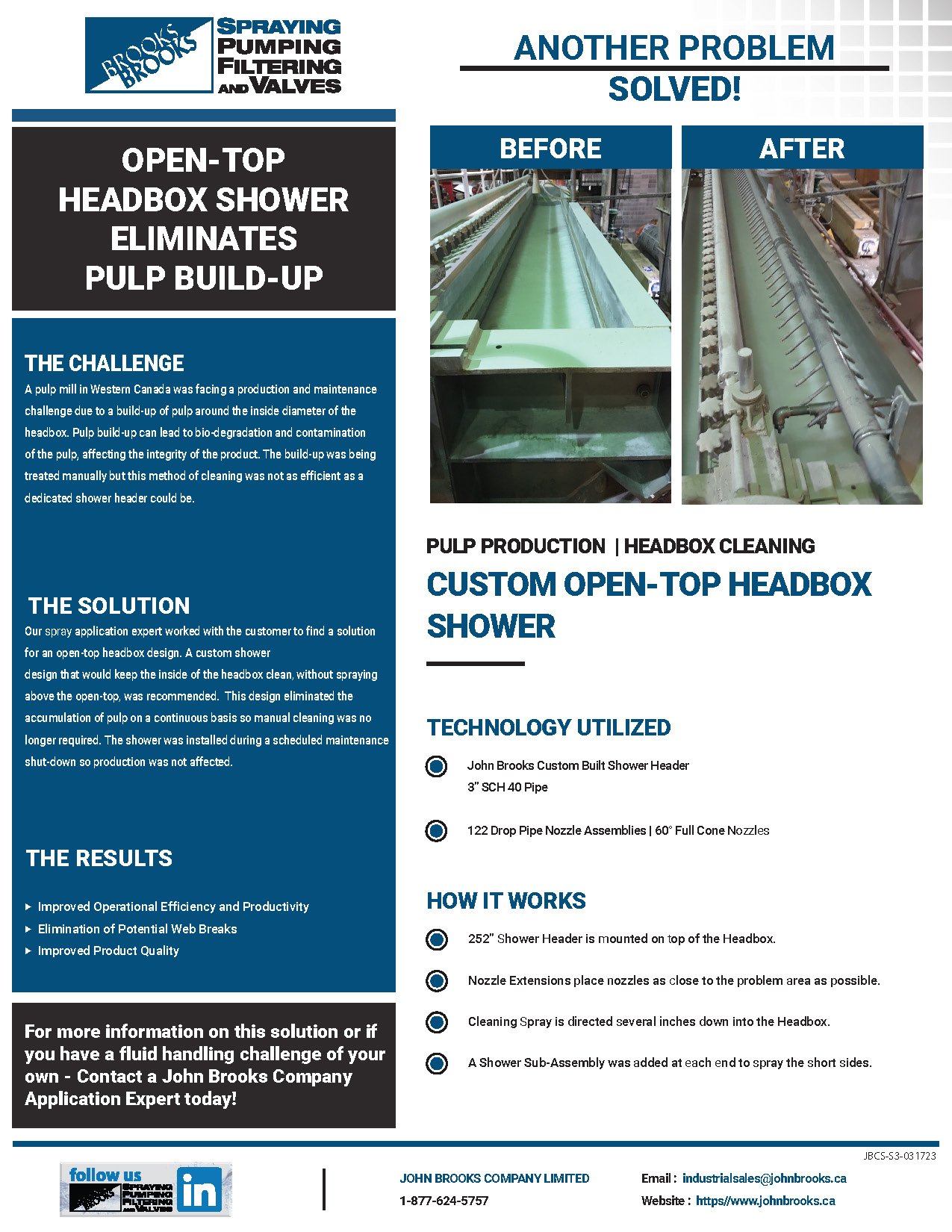

A pulp mill in Western Canada was facing a production and maintenance challenge due to a build-up of pulp around the inside diameter of the headbox. Pulp build-up can lead to bio-degradation and contamination of the pulp, affecting the integrity of the product. The build-up was being treated manually but this method of cleaning was not as efficient as a dedicated shower header could be.

THE SOLUTION

Our spray application expert worked with the customer to find a solution for an open-top headbox design. A custom shower design that would keep the inside of the headbox clean, without spraying above the open-top, was recommended. This design eliminated the accumulation of pulp on a continuous basis so manual cleaning was no longer required. The shower was installed during a scheduled maintenance shut-down so production was not affected.

THE RESULT

- Improved Operational Efficiency and Productivity

- Elimination of Potential Web Breaks

- Improved Product Quality

TECHNOLOGY UTILIZED

- John Brooks Custom Built Shower Header 3” SCH 40 Pipe

- 122 Drop Pipe Nozzle Assemblies | 60° Full Cone Nozzles

HOW IT WORKS

- 252” Shower Header is mounted on top of the Headbox.

- Nozzle Extensions place nozzles as close to the problem area as possible.

- Cleaning Spray is directed several inches down into the Headbox.

- A Shower Sub-Assembly was added at each end to spray the short sides.

Resources

Talk to one of our Experts

Reach out to our team of Spraying, Pumping, Filtering, Valve, and Systems Specialists today. We know we can help you with any municipal or industrial application challenges.