Introduction to Pressure Gauges and How They Measure Water Pressure

What Are Pressure Gauges?

A pressure gauge is a device that measures the pressure of fluids, gas, or vapours in a pressure-powered unit to make sure there are no leaks or pressure variations that could impact the system's performance. Pressure systems are required to work within a specific range of pressures. Any divergence from the acceptable ranges can have a significant impact on the system's operation. For instance, too low or too high pressures can have a negative impact on product yield and quality and can potentially pose a safety hazard to system operators. That’s why in the industrial sector, pressure gauges are coveted for their ease of use, precision, cost-effectiveness, and ease of maintenance.

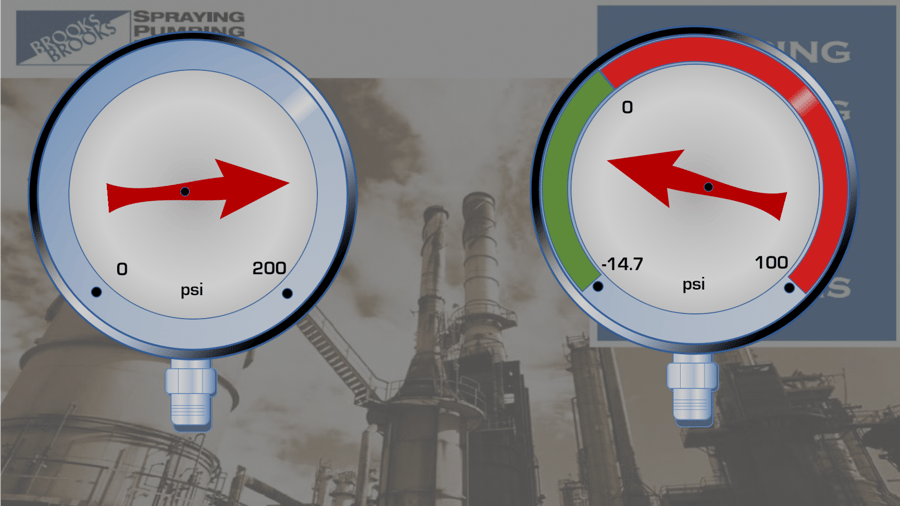

There are two basic types of gauges found in pumping systems: pressure gauges (on the left) and compound gauges (on the right), which measure both vacuum and pressure.

How to Measure Water Pressure with a Pressure Gauge?

Pressure monitoring is critical for the safe and proper operation of a variety of industrial systems. Without an accurate mechanism to measure and alter the pressure, entire fluid power systems would be erratic and unreliable and, hence, useless.

Measuring liquid pressure using a pressure gauge is critical for maintaining mechanisms that rely on appropriate pressure control and properly operating mechanisms that rely on pressure control values.

Pressure gauges can be used for several purposes. For example, the water or air that travels through our household water systems and tanks makes them work. A pressure gauge is used to check for faults in the tanks or systems by measuring the force of pressure in the water or air. You can use them on a well system's storage tank to ensure that the pump turns on and off appropriately.

Industrial usages include utilizing gauges on water treatment machinery and reverse osmosis systems, where pressure is a critical component of the system's performance.

How Do Pressure Gauges Work in Pumping Systems?

If you're wondering, "What should the water pressure in my pumping system be?" you should know that water pressure regulators that are used in municipal water supply systems distribute water to property holes at 50 to 70 PSI.

There is an easy way of testing your water pressure if you think it is either too high or too low: use a PSI-measuring pressure gauge.

There are two basic types of gauges found in pumping systems, pressure gauges and compound gauges, which measure both vacuum and pressure.

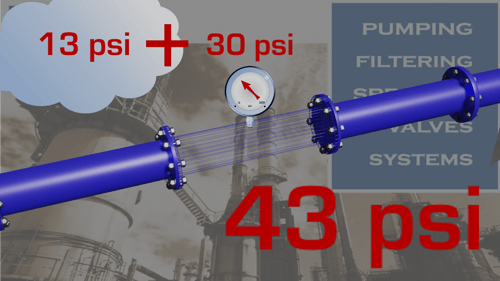

All gauges indicate the difference in pressure between the port and the outside environment. For example, if we have a pressure gauge installed in a pipe that reaches 30 PSI and the environmental pressure is 13 PSI absolute, the absolute pressure in the pipe would be 43 PSI.

Note: Zero absolute pressure is a perfect vacuum. Now, if there was a compound gauge in the pipe that is reading a negative value, then the pipe pressure is below the environmental pressure; we would say this pipe is under a vacuum.

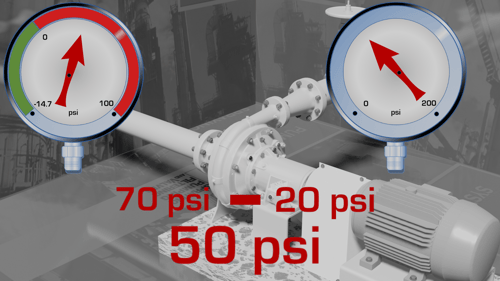

For understanding purposes, let’s consider a centrifugal pump installed in a piping system. We have a compound gauge installed on the suction of the pump and a pressure gauge installed on the discharge of the pump. Here, the amount of pressure the pump adds to the system or boosts can be calculated by taking the discharge pressure and subtracting the suction pressure.

John Brooks Company is an authorized distributor of Pressure Gauges

Since there are so many variables that go into choosing a good pressure gauge, one of the best decisions pressure gauge buyers can make is to invest time and money in a reputable pressure gauge provider.

At John Brooks Company, we offer you a broad range of pressure gauges. Working with a reputable supplier like us will guarantee that you get the most out of our pressure gauges for your specific application.

Contact us today to learn more or to book a consultation with one of our application experts.