Alfa Laval has over 100 years of experience in the food and beverage, pharmaceutical and beauty industries, providing modern tank-cleaning devices. Alfa Laval tank and tote cleaning devices are well known for reduced water consumption. They offer product efficiency and various benefits to workforce safety and the environment.

Downtime Efficiency

Alfa Laval's tank and tote cleaning processes allow for more efficient cleaning time. They are designed and sized from the beginning. Each tank cleaning device is optimized for the target application and operates with less energy and waste.

Replacing manual cleaning processes with automated tank cleaning methods achieves higher productivity, lower operating costs, and more time for prioritized tasks. Higher profitability is achievable with these savings, and production goals are easier to meet.

Workforce Safety

Industrial vessels can provide inherent risk upon entry if not assessed carefully. Alfa Laval offers mechanical tank cleaning processes that give an alternative to manual cleaning. These alternatives help companies to create a safer working environment.

Quality Impact

Alfa Laval has more than a century of experience in equipment design. Their designs ensure batch-to-batch reliability and energy saved in the cleaning process.

The quality of the Alfa Laval tank and tote cleaning devices is dependent on the control of the tank cleaning process for each piece of equipment. Their objective is to obtain consistent, precise, dependable results after each production cycle.

Less is More: Reducing Water Consumption

The saying "less is more" rings true as water conservation is becoming increasingly important in North America. As more processing and manufacturing companies reduce water usage in daily production activities, organizations are interested in making a positive environmental impact.

Reduce your Water Consumption for Tank Cleaning by 80%

Alfa Laval has modernized its technology with new tote and tank cleaning devices. These devices reduce water consumption, enabling users to meet challenging requirements.

How Clean is Your Tank?

Adequate tank cleaning in the food, beverage, pharmaceutical and personal care industries can be challenging. A high risk of product contamination can occur when adjudicators, connectors and coils create shadow areas.

Today, utilizing these four tank-cleaning technologies will ensure proper sanitation.

1. The Alfa Laval PlusClean® Cleaning Nozzle

Alfa Laval's new PlusClean Cleaning Nozzle provides 100% cleaning coverage regardless of specific tank design. Applied during Cleaning-In-Place (CIP), PlusClean reduces chemical and water consumption by up to 80%, making this a more sustainable choice than static spray balls.

Installed flush with the tank wall allows the Alfa Laval PlusClean Cleaning Nozzle to be used with tanks where the internals are close to the tank wall and doesn't interfere with other tank components.

Benefits of the Alfa Laval PlusClean® Cleaning Nozzle:

- 100% cleaning coverage in shadow areas, ensuring batch and continuous process changeovers are safe, quick, and free from contamination

- Easy to install and simple to use

- Eliminates risk due to high impact and optimized spray pattern

- Quick Return on Investment

- Reduces up to 80% water, cleaning solutions and energy due to its highly efficient, low-pressure tank cleaning.

2. The Alfa Laval PlusClean® UltraPure Cleaning Nozzle

With its optimized, high-impact spray pattern, PlusClean UltraPure cleaning nozzles deliver 100% cleaning coverage in shadow areas, such as beneath agitator blades, coils, and connections, that top-mounted tank cleaning devices can't reach. Faster, safer contaminant-free changeovers are now achievable, boosting batch or continuous process productivity in the biotech and pharmaceutical industries.

Benefits of the Alfa Laval PlusClean® Ultra Pure Cleaning Nozzle:

- Cut ownership costs due to low maintenance requirements and reduced water, cleaning agent and wastewater costs

- Eliminate product contamination risks and increase product yield

- Get 100% cleaning coverage

- Meet the sterile and aseptic process requirements in the biotechnology and pharmaceutical industries

- Up to 80% reduction in water and cleaning agent consumption

3. Alfa Laval Rotary Spray Heads

Alfa Laval Rotary Spray Heads can save up to 30% on solvent and water usage using this device compared to standard technologies like the static spray ball.

The Rotary Spray head disperses fans of water in a rotating flat fan spray. This spray sanitizes tanks more efficiently and increases tank wall coverage. Delivering frequent and moderate-level force allows challenging and stuck-on debris to dislodge from the tank walls. The tank cleaning is completed faster during this process, eliminating costly downtime.

In addition, the rotary spray head allows for retrofitting, ensuring the proper spray technology for your application needs.

Benefits of the Alfa Laval Rotary Spray Heads

- 40% faster cleaning times than the traditional static spray balls, resulting in more uptime

- 40% savings in cleaning solutions and water compared to static spray balls

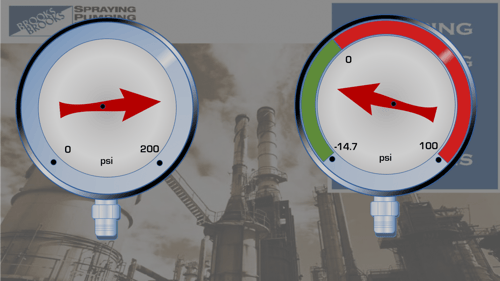

- Delivers a medium impact level of 15-40 PSI

- Easy to retrofit into tanks without having to adjust flow rates or supply pressures

- Eliminates the risk of contamination through its hygienic and safe design

- Increased cleaning efficiency and lower ownership costs make it more sustainable than static spray balls.

- Self-cleaning and self-draining, offering easy installation, inspection, and disassemble

4. The Alfa Laval Rotary Jet Head

Alfa Laval Rotary Jet Heads are so effective that they can reduce cleaning times by more than 50% and water and chemical consumption by 70% compared to traditional static spray balls.

The Alfa Laval Rotary Jet Head uses a high-impact jet stream to thoroughly clean. The water jets move in a pre-defined 360-degree rotation, with impingement being its main cleaning criterion. The Alfa Laval Rotary Jet Head delivers faster and more reliable tank cleaning by reducing energy, time, chemicals, and water. This solution increases productivity and product quality.

Benefits of the Alfa Laval Rotary Jet Head:

- Alfa Laval Q doc-documentation including EN 10204 (MTR) 3.1.B, FAT and SAT, and ATEX certificates

- Compliant with Good Manufacturing Practices (cGMP) for Alfa Laval UltraPure portfolio for sterile processes

- Improves safe working conditions using automation and eliminating confined space entry

- Powerful design

- Proven cleaning validation for hygienic process through protected process integrity

- Saves time, cleaning media and water

- Sufficient for tank cleaning in the food, beverage, personal care and pharmaceutical industries

To further reduce the risk of contamination, the rotary jet head has hygienic self-cleaning construction, allowing the cleaning solution to reach the outsides of the rotary jet head. This self-cleaning element helps eliminate the risk of a product recall or product loss.