ARTIFICIAL LIFT SOLUTIONS

Using a combination of HYDRA-CELL PRO Surface Equipment and JJ Tech Select-Jet Hydraulic Jet Pumps, you can enhance well production while reducing maintenance costs and minimizing workovers, even in the most challenging wells.

diaphragm SURFACE pumps

Benefit from longer run times and lowered maintenance costs with Wanner's seal-less design with no packing that could wear and fail. CLICK TO LEARN MORE

HYDRAULIC Jet pumps

Increase production efficiency with the most versatile jet pump in the industry that can be installed in vertical, deviated and horizontal oil and gas wells. CLICK TO LEARN MORE

-

What is Artificial Lift

Artificial lift refers to the use of surface energy (hp) to lift fluids from a wellbore.

Artificial lift systems are used to decrease bottom-hole pressure on the formation to increase the flow of fluids, such as crude oil, water, or natural gas from a producing well.

Artificial lift is used in wells that have insufficient pressure from the reservoir to force the formation fluids (hydrocarbons) to the surface but can also be used in naturally flowing wells (that technically do not need it) to increase the flow rate above what would flow without lift.

Generally, artificial lift employs a mechanical pump inside the well, which is used to decrease the hydrostatic column of fluid in a wellbore that is exerting backpressure on the reservoir. The fluid pumped from the well may be oil, water, natural gas, or a mixture of some or all of these.

-

Types of Artificial Lift Systems

- Sucker Rod Pump uses a system of reciprocating rods to actuate a downhole positive-displacement pump.

- Electric Submersible Pump (ESP) is a submerged multistage centrifugal pump that is installed on the end of the production tubing. A downhole electric motor is supplied power via a cable that is run from the surface and is banded to the outside of the tubing.

- Gas Lift uses a compressor and a system of mandrels to inject natural gas into the wellbore and lighten the column of fluid holding backpressure on the formation.

- Progressing Cavity Pump (PCP) uses a system of rotating rods to actuate a downhole positive-displacement pump.

- Jet Pump uses fluid power from a surface pump to power a downhole Venturi Pump.

COMPARISON

-

Artificial Lift Systems for Challenging Wells & Applications

JJ Tech has been providing effective artificial lift solutions in challenging wells for over 20 years. If challenging well conditions are compromising the production of your well, contact JJ Tech. An analysis of your current artificial lift system is the first step in overcoming your well production challenges.

JJ Tech provides artificial lift solutions that enable wells to be produced effectively despite a range of downhole issues:

- Horizontal or Deviated Wells

- Liquid-Loaded Wells

- High Sand Content | High Solids Producing Oil Wells

- Frac Flowback

- Gas Wells (Dewatering)

- Highly Corrosive Wells

Horizontal or Deviated WellsWhen a wellbore is crooked or deviated, the working life of most artificial lift systems is drastically shorter due to excessive wear on the moving (reciprocating or rotating) components. Also, other forms of artificial lift are subject to damage during installation in deviated wells.

Hydraulic Jet Pumps have no moving parts downhole, therefore downtime is greatly reduced between costly workovers.

Liquid-Loaded Wells

Common in the later stages of a well’s lifecycle, particularly gas wells, liquid-loaded wells are characterized by an accumulation of fluids from water and hydrocarbon condensates. This condition significantly decreases the well’s performance and efficiency. The accumulation of liquid can form a column in the well, creating backpressure on the formation that slows down or even halts the flow of gas to the surface.

JJ Tech’s hydraulic jet pump solutions have proven extremely effective in liquid-loaded wells that need extra power to push fluid to the surface.

High Sand Content | High Solids Producing Oil Wells

Wells that produce solids (formation or frac sand) can quickly damage moving components in most forms of artificial lift. Since JJ Tech hydraulic jet pump systems have no moving parts downhole, much longer run times are achievable with greater reliability and fewer workovers. JJ Tech offers tungsten and boron carbide components that are highly-resistant to abrasives. The JJ Tech solution often provides years of uninterrupted production without costly workovers.

Frac Flowback

We call it FRAC-EVAC. We achieve faster frac-flowback using a patented JJ Tech Jet Pump. The jet pump is set in the tubing string above a packer, which is set just above the perforations. Power fluid (water) is injected down the tubing through a nozzle. The power fluid and produced (frac) fluids are then combined in the throat (the Venturi Effect) and return up the tubing-casing annulus. The power for FRAC-EVAC is provided by JJ Tech’s ULTRA-FLOW production system. This patented process combines the JJ Tech Hydraulic Jet Pump with a powerful diaphragm surface pump by Wanner Engineering Inc. This award-winning diaphragm pump has no seals and is packing free, unlike the conventional triplex plunger pump. Not only does the seal-less design reduce downtime and maintenance, it is also an environmentally sound option, preventing oil and saltwater leakage. The Hydra-Cell PRO T100K Diaphragm Pump is capable of 1550 BPD at 3000 PSI.

Gas Well Dewatering

The JJ Tech hydraulic jet pump utilizes the Venturi Effect to pull wellbore fluids into a flow stream that is pumped downhole and back up again through a concentric string configuration. The key components of the jet pump assembly are flow-reversible and don’t require a service rig intervention to retrieve, inspect, service or change them. Pump component changeouts are a one-person operation that requires only one to two hours to perform. The jet pump can run on the end of the integral joint or coiled tubing inside of standard production tubing. The innovative, patented JJ Tech hydraulic jet pump design uses larger fluid input areas and cleaner flow geometries, allowing operation with efficiency equal to or greater than conventional artificial lift systems. These features also facilitate the movement of solids, i.e. sand, through the jet pump, making it ideal for production with high solid content.

JJ Tech’s jet pump is the downhole component of the company’s patented ULTRA-FLOW production system. It is combined with a T100 series high-pressure diaphragm surface pump, developed for JJ Tech by Wanner Engineering Inc. This rugged, reliable pump greatly reduces environmental and maintenance issues associated with conventional triplex pumps. The T100S, rated at 5000 PSI and 905 BPD is well suited for concentric string completions used with gas well dewatering, where smaller fluid conduits require higher pressures due to fluid friction through the smaller strings of pipe.

The Hydra-Cell PRO surface pumps are closed systems with cartridge-type check valves and diaphragms for ease of maintenance and lower operating costs. Units are configured with natural gas engines or electric motors with variable-frequency drives (VFDs) to reduce operating costs and pump wear.

ADVANTAGES OF THE JJ TECH GAS WELL DEWATERING SOLUTION

- There are no moving parts downhole.

- It can move large volumes of fluid with moderate to high solid (sand) content.

- It increases production rates as hydrostatic head is reduced.

- It increases recoverable reserves as more gas can move into the wellbore.

- Proprietary software provides formation monitoring and performance optimization.

- They can run horizontally.

Highly Corrosive Wells

Some wells produce corrosives, such as hydrogen sulfide or carbon dioxide, that can damage the wellbore components if they are not properly treated. These corrosives can also damage artificial lift systems components if they are composed of vulnerable materials.

Hydraulic Jet Pump systems help protect casing, tubulars, and artificial lift components by continuously injecting corrosion inhibitors downhole. JJ Tech offers artificial lift components manufactured of materials that endure different types of corrosives. Our standard material is 17-4 PH stainless steel, but we offer more corrosion-resistant materials such as Inconel and Hastelloy to reduce or eliminate corrosion-stress cracking.

-

How Jet Pump Systems Work

Jet pump systems work by utilizing a surface pump which pumps fluid (power fluid) to the downhole jet pump in a continuous loop. The jet pump bottom-hole assembly is set above a packer because all jet pump systems need two fluid conduits to work. Upon entering the jet pump, the high-pressure power fluid passes through a nozzle, where the resulting pressure drop allows formation fluid (produced fluid) to pass through a standing valve and enter the jet pump. The power fluid and produced fluid combine together in the “mixing tube” and the combined fluids return to the surface via the casing.

-

Videos

JJ Tech Artificial Lift Bottom Hole Jet Pump

Hydra-Cell T100 Series Packing-Free Triplex Pumps

T100 & Q155 Low Pressure Diaphragm Disassembly and Maintenance

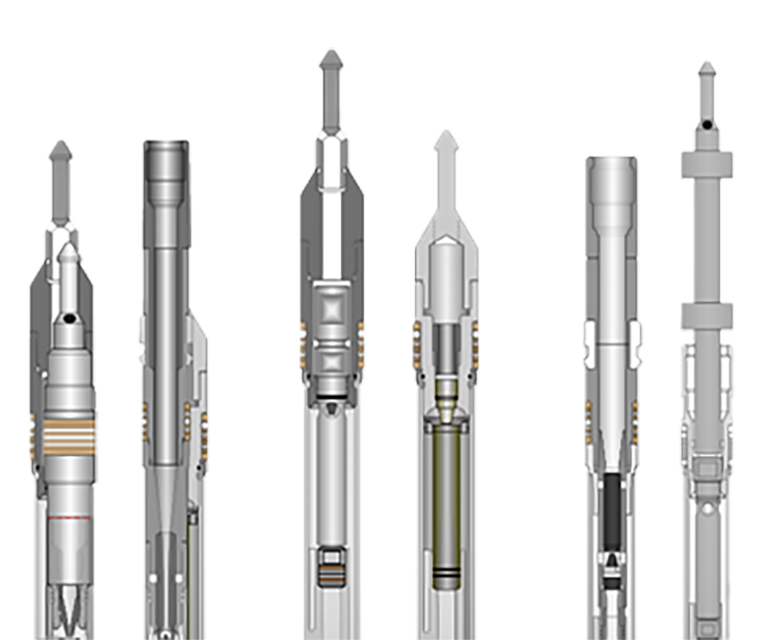

jj tech select-jet hydraulic jet pump for artificial lift

With the capability of being installed in both deviated and horizontal wells the patented line of JJ Tech jet pumps makes them some of the most versatile artificial lift systems in the industry. Whether it’s due to sand and solids production or gas locking from a high GLR, the JJ Tech jet pump is an ideal solution for troublesome wells. Combined with no moving parts downhole and a hydraulically retrieved carrier assembly, the JJ Tech jet pump eliminates the workover rig for routine maintenance.

FEATURES

- Versatile Bottom Hole Assembly with High Flow Capacity

- All Viton Elastomers (O-Rings)

- PEEK/Teflon Vee Packing

- 17-4 PH Stainless Steel – Standard (QPQ)

- Premium Materials Include :

- Inconel 625

- Hastelloy X

- 316 Stainless Steel

- 420 Stainless Steel (Boron Carbide Clad)

hydra-cell pro diaphragm pumps

WANNER Hydra-Cell PRO pumps feature an exclusive seal-less diaphragm design that eliminates packing and plunger wear, leakage, external lubrication, and emission – resulting in lower costs of ownership and maintenance as well as longer service life than traditional packed pumps.

T100 SERIES

LOW PRESSURE

Models: T100E, T100F, T100H

Max. Flow Rate: 96 gpm (366.1 l/min) 3292 BPD

Max. Pressure: 2100 psi (145 bar)

T100 series

medium pressure

Models: T100K, T100M

Max. Flow: 45 gpm (170.4 l/min) 1543 BPD

Max. Pressure: 3500 psi (241 bar)

T100 series

high PRESSURE

Model: T100S

Max. Flow: 26 gpm (98.4 l/min) 891 BPD

Max. Pressure: 5000 psi (345 bar)

T200 SERIES

MEDIUM PRESSURE

Models: T200K, T200M

Max. Flow: 93 gpm (352 l/min) 3189 BPD

Max. Pressure: 3500 psi (241 bar)

T200 series

HIGH pressure

Models: T200P, T200Q

Max. Flow: 72 gpm (272 l/min) 2469 BPD

Max. Pressure: 4500 psi (310 bar)

Q155 series

LOW PRESSURE

Models: Q155E, Q155F, Q155H

Max. Flow: 157 gpm (595 l/min) 5383 BPD

Max. Pressure: 2100 psi (145 bar)

Q155 SERIES

MEDIUM PRESSURE

Models: Q155K, Q155M

Max. Flow: 78 gpm (295 l/min) 2674 BPD

Max. Pressure: 3500 psi (241 bar)

q330 series

LOW pressure

Models: Q330E, Q330F, Q330G

Max. Flow: 330 gpm (1249 l/m) 11312 BPD

Max. Pressure: 2000 psi 138 bar)

q330 series

medium pressure

Models: Q330K, Q330M

Max. Flow: 153 gpm (579 l/m) 5247 BPD

Max. Pressure: 3500 psi (241 bar)

Q330 series

high PRESSURE

Models: Q330P, Q330Q

Max. Flow: 118 gpm (446 l/min) 4047 BPD

Max. Pressure: 4500 psi (310 bar)

request a no-cost well analysis

see how you can optimize production and reduce capital & operating costs

Submit your well data, and we’ll contact you to discuss how we can optimize your well’s production and efficiency. Please fill in all blanks with your latest known well data and specify units of measurement where applicable.